Stepping type magnesium alloy coiled strip annealing furnace

A magnesium alloy, step-by-step technology, applied in the direction of furnace, furnace type, heat treatment furnace, etc., can solve the problem that the annealing furnace cannot be applied to the coil annealing treatment of magnesium alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

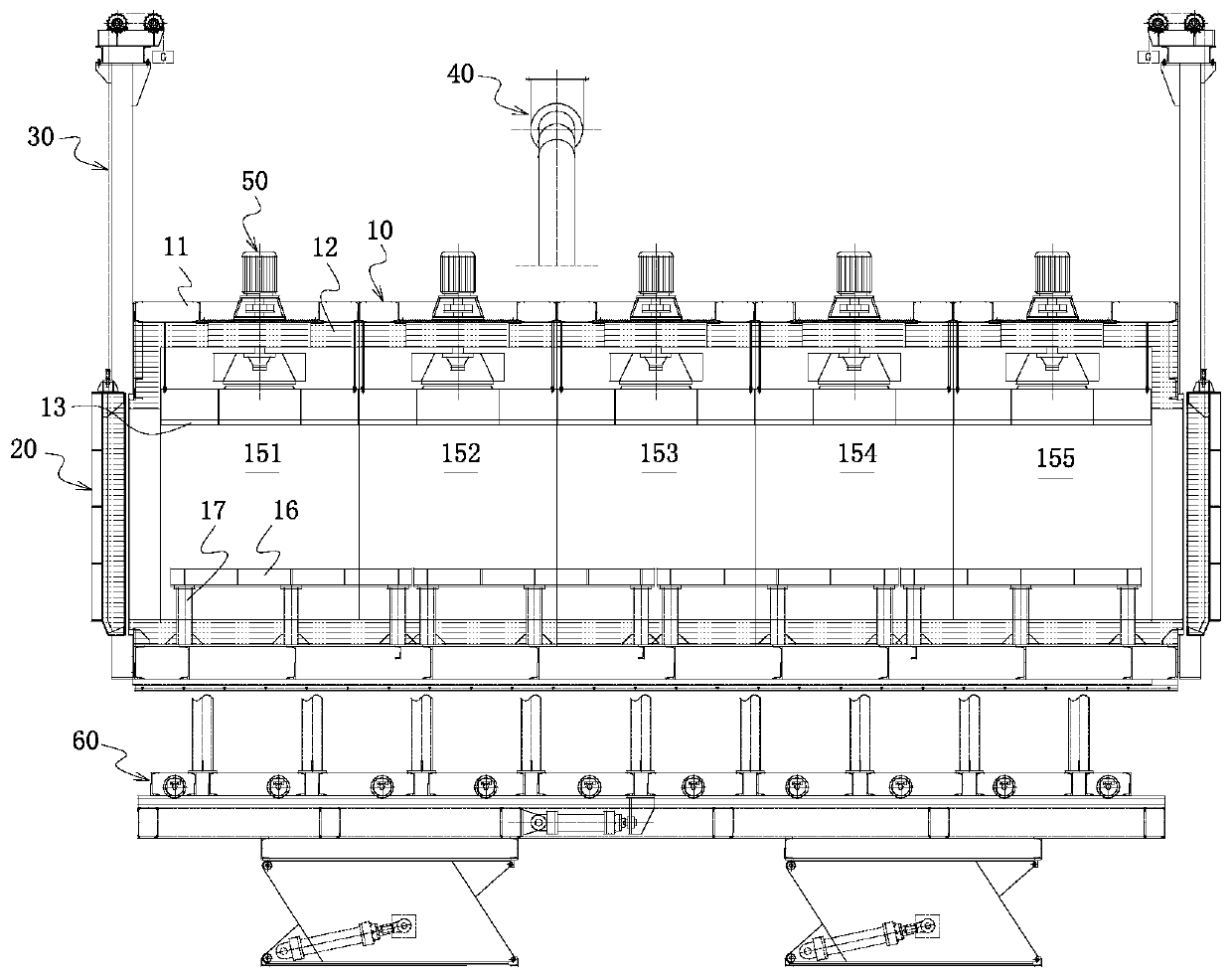

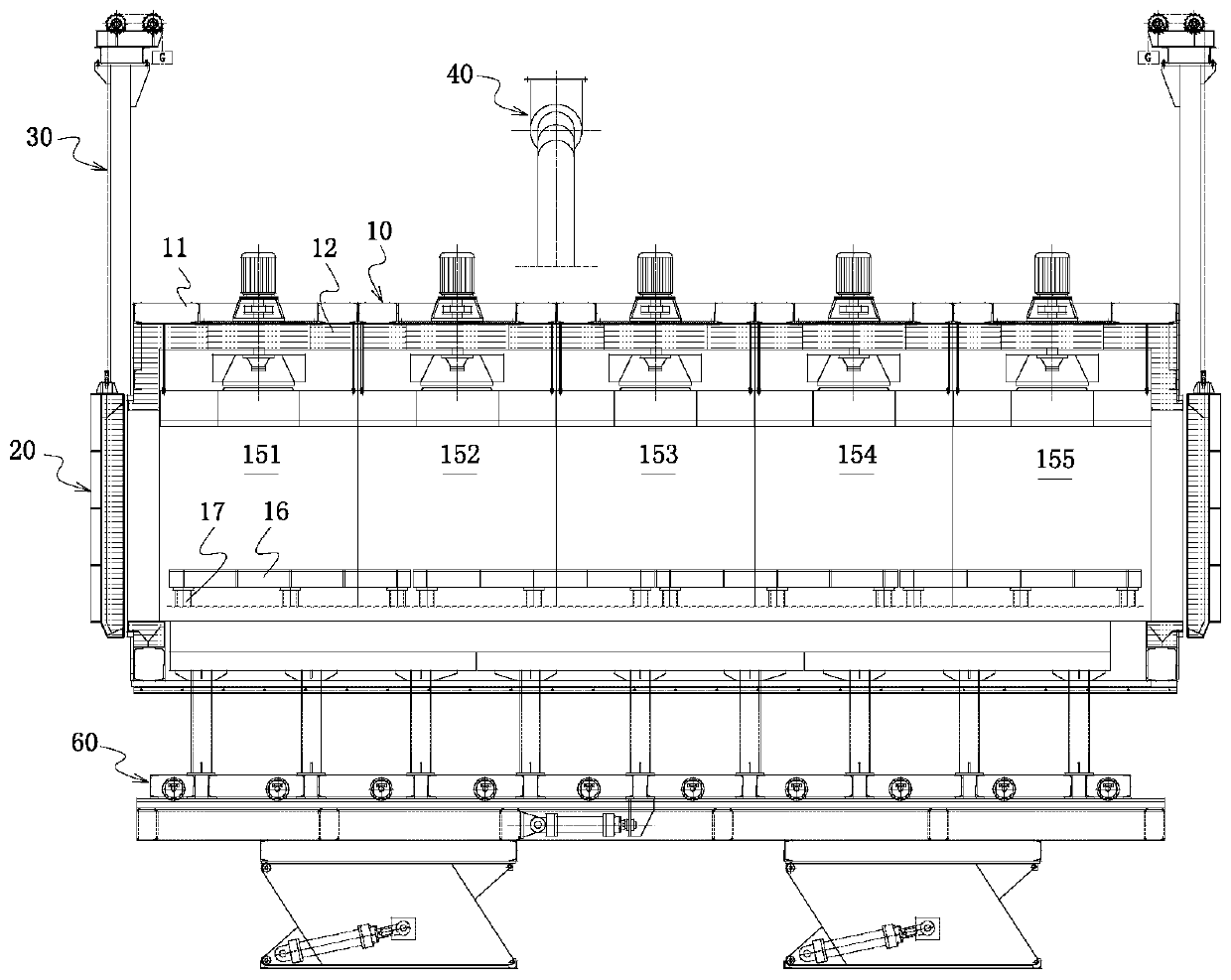

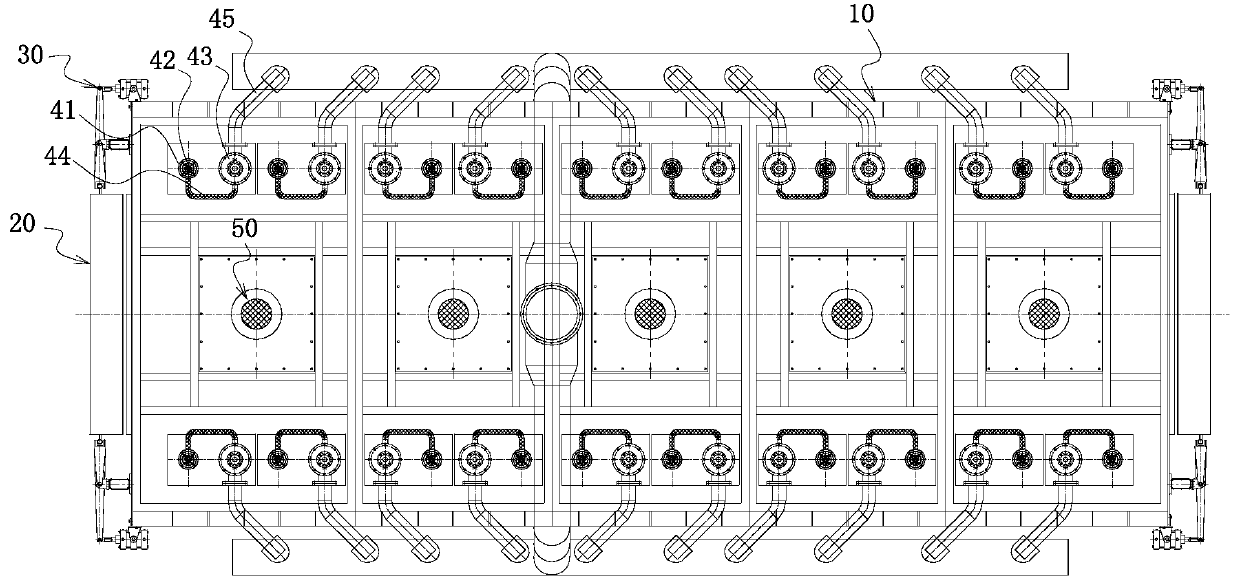

[0027] refer to Figure 1 ~ Figure 4 , the present embodiment provides a step-by-step magnesium alloy strip annealing furnace, comprising a box-type furnace body 10, furnace doors 20 are provided on the front and rear sides of the furnace body, and a furnace wall 13 is provided in the furnace body, and the furnace wall longitudinally divides the furnace chamber It is divided into two parts, the furnace 15 and the flue 14. The flue 14 is surrounded by the top surface of the furnace and the left and right sides. 15 includes more than two heating zones, each heating zone is equipped with a circulation fan 15 in the top flue, the fan inlet is connected to the furnace 15, and the fan outlet is connected to the flue 14; Radiant tube heating device 40, the center of the bottom wall of the furnace body is provided with a lower opening 18 extending along the length direction of the furnace, and the left and right sides of the lower opening are provided with supporting beams 16 for supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com