Ink-jet printing trolley and ink-jet printing device

A technology for inkjet printing and ink supply devices, which is applied in printing devices, printing, typewriters, etc., and can solve problems such as weight increase, printing car structure stress mode and running stability discount, nozzle nozzle precision splicing problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0034] It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiment of the present invention are limited to relative positions on the designated view, not absolute positions.

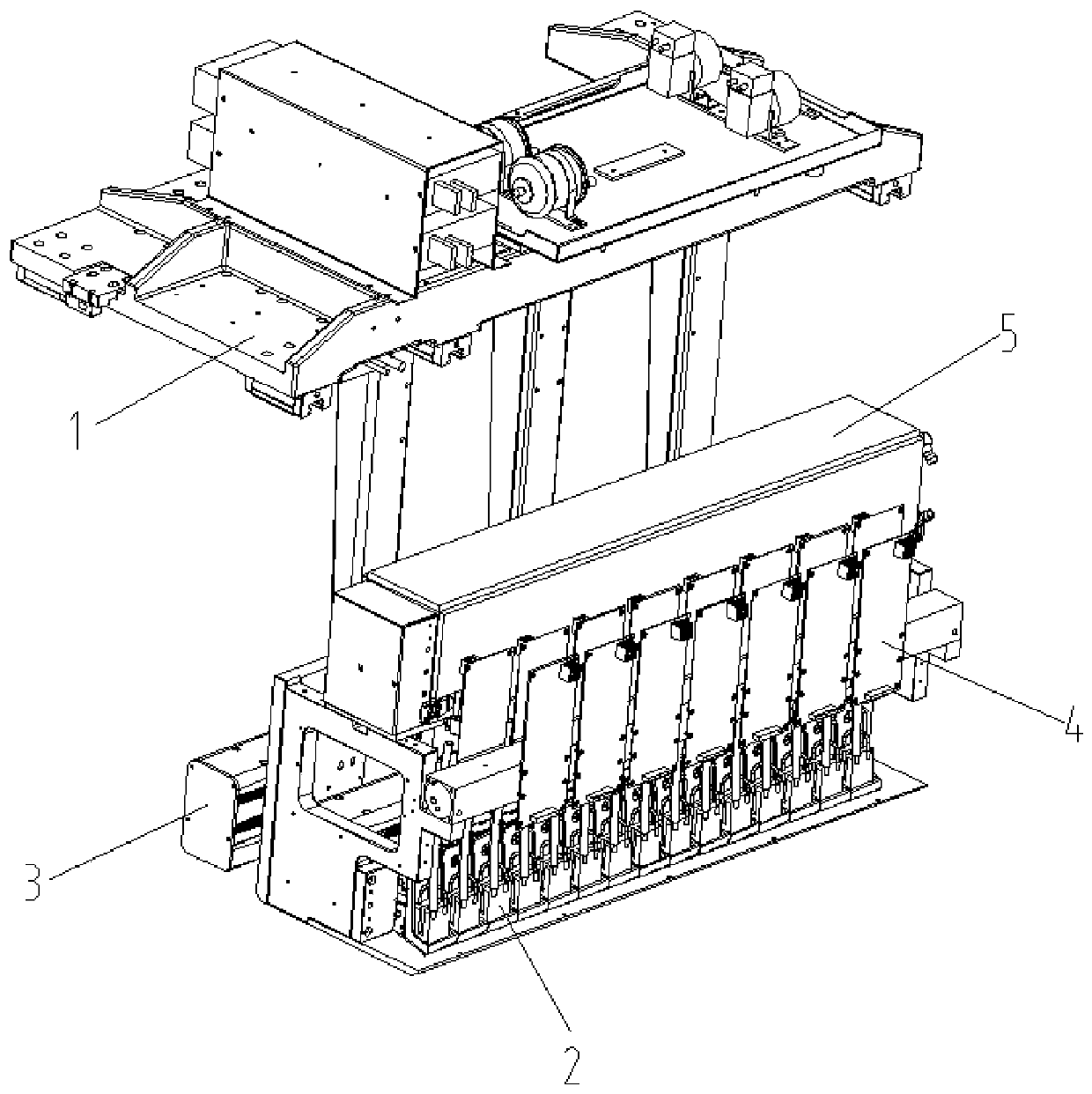

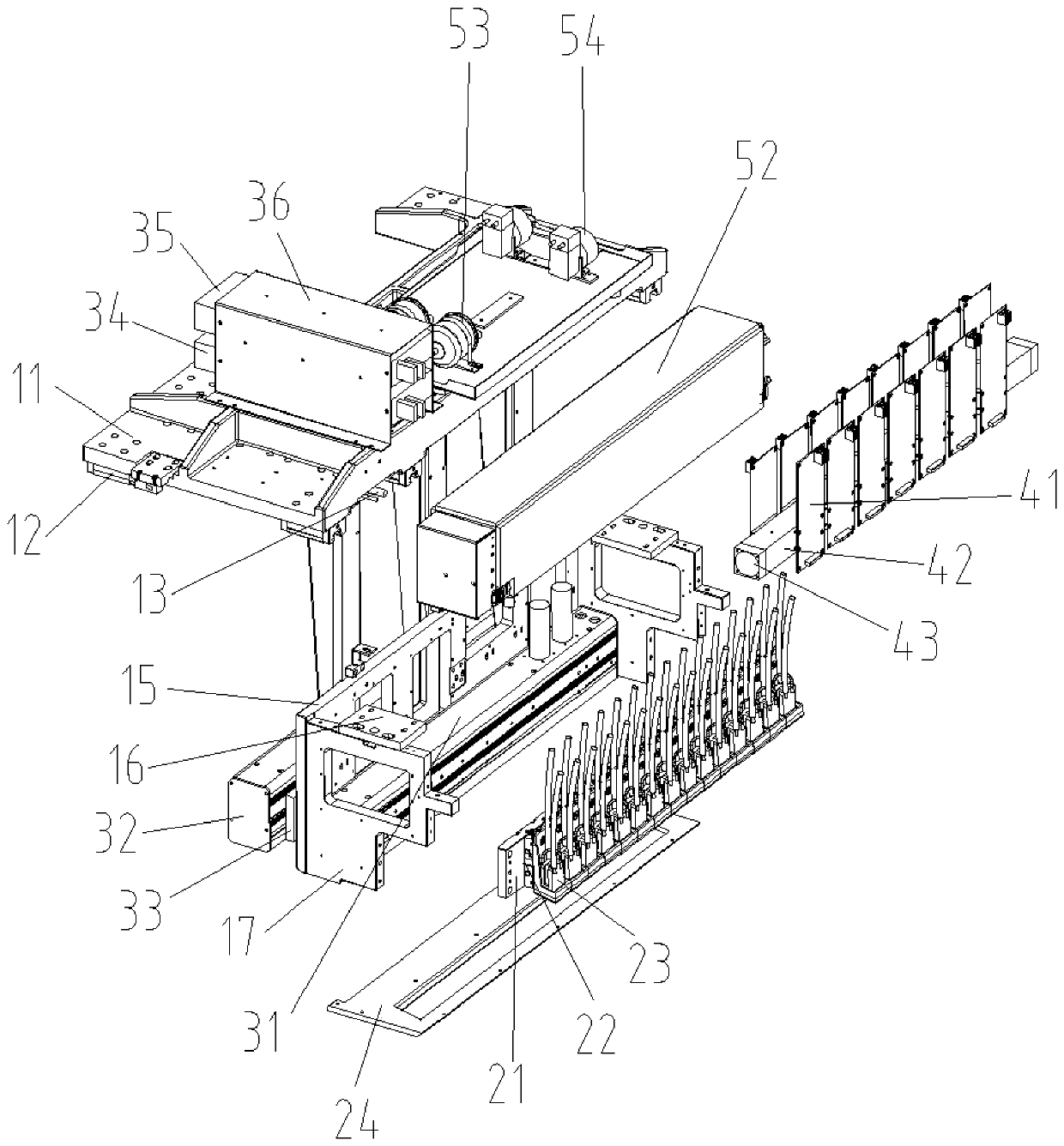

[0035] See Figure 1 to Figure 3 , The present invention provides an inkjet printing cart, which includes: a cart support assembly 1, a printing module 2, a curing module 3, a nozzle control module 4, and an ink supply device 5. The trolley support assembly 1 is slidably installed on the beam of the equipment, and is used to carry the printing module 2, the curing module 3, the nozzle control module 4 and the ink supply device 5. The jet printing module 2 is used to print graphics and text on the printing medium, which can meet the printing requirements of different wide-format printing media. The curing module 3 is used for curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com