Rapid welding manipulator

A fast welding and manipulator technology, applied in the field of manipulators, can solve problems such as faults at the movable joints of welding manipulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

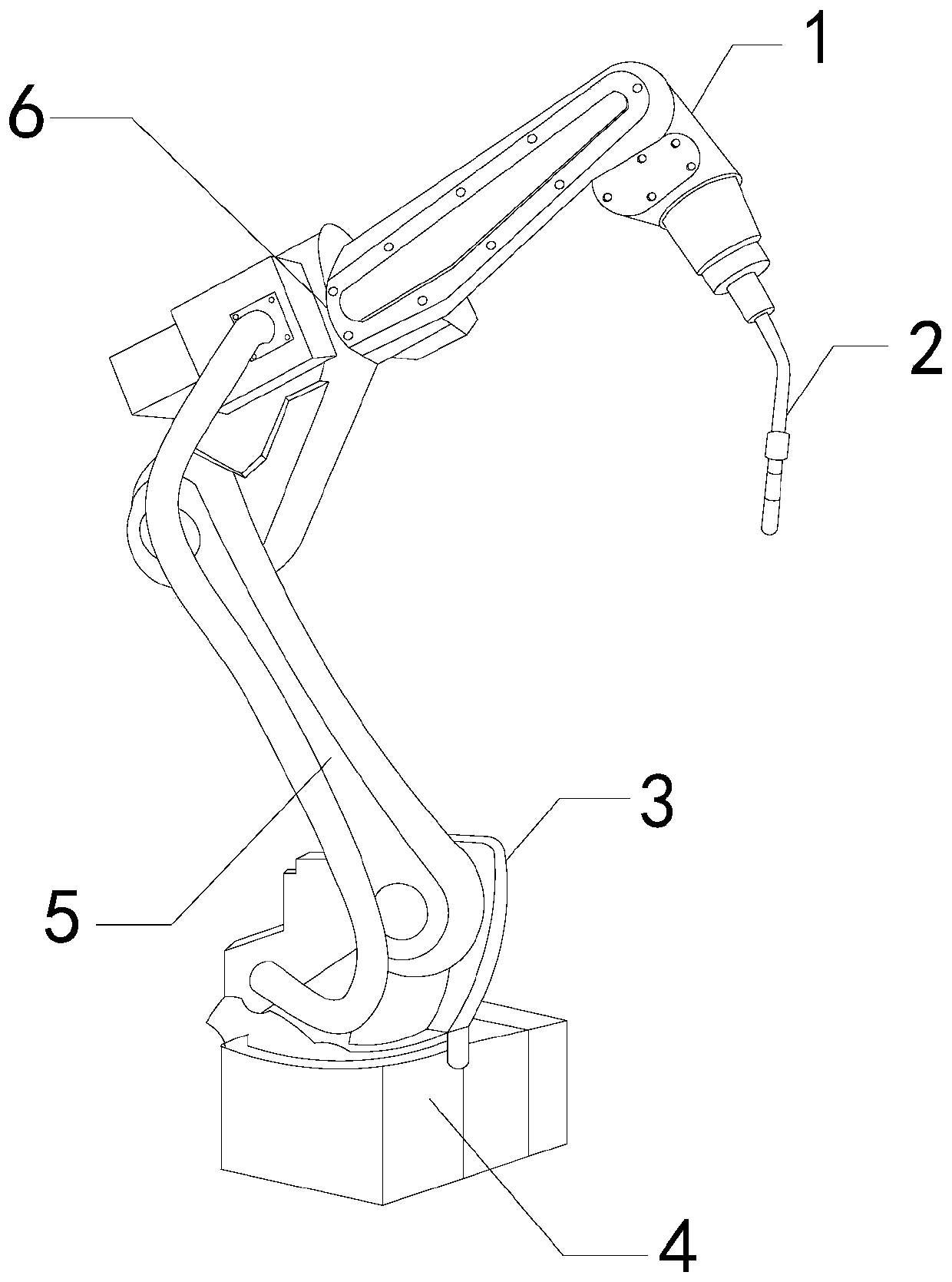

[0031] For example figure 1 -example Figure 7 Shown:

[0032] The invention provides a fast welding manipulator, the structure of which includes a manipulator 1, a welding torch 2, a steering support 3, a base 4, an engaging rod 5, and a movable rod 6. The welding torch 2 is embedded and connected to the manipulator 1, and the steering support 3 is movably engaged with the base 4, the base 4 is fixed at the lower end of the manipulator 1, the movable rod 6 is connected with the connecting column 5, and the connecting rod 5 is movably engaged with the steering support 3.

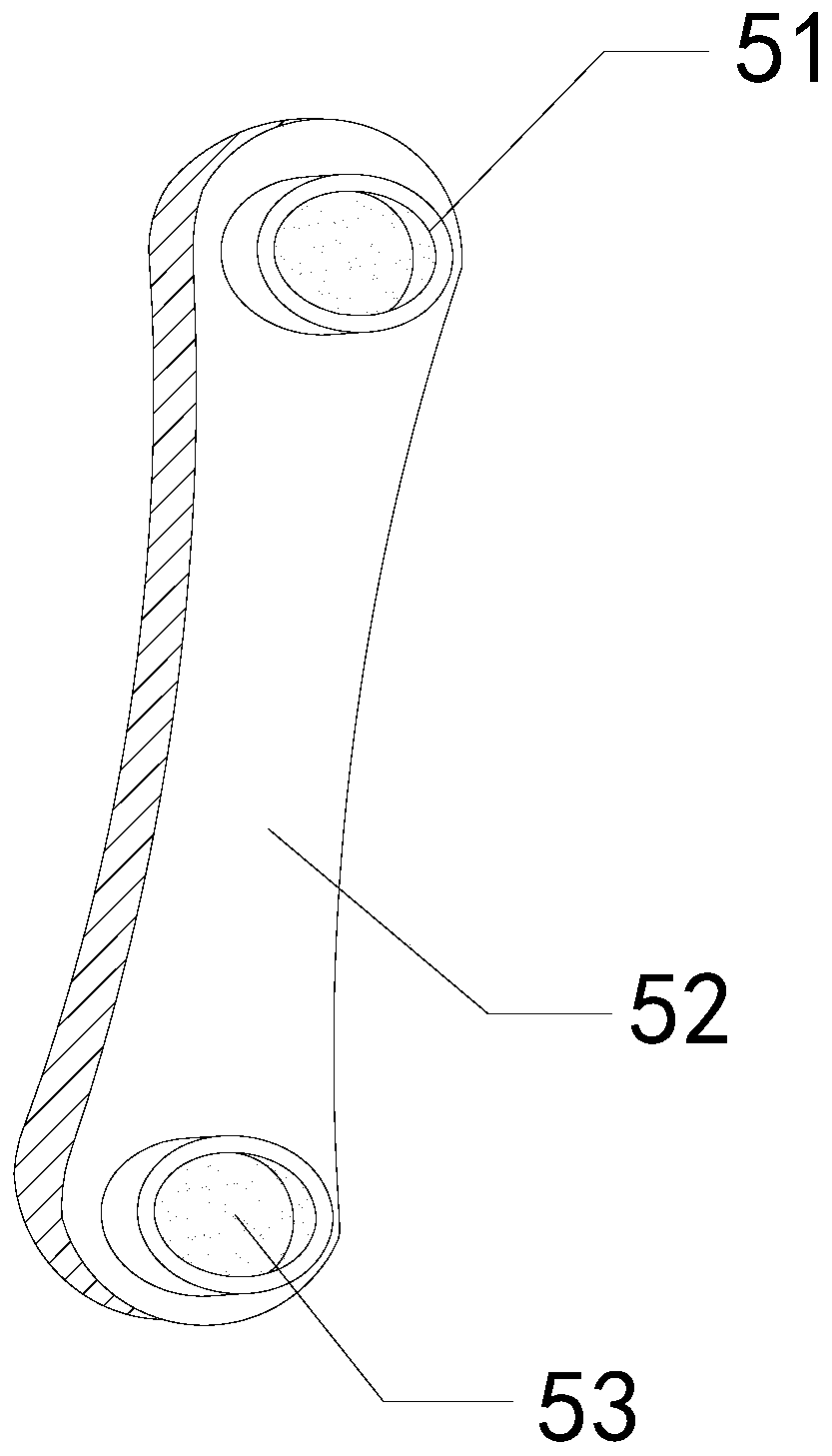

[0033] Wherein, the connecting rod 5 includes a shield 51, a fixed rod 52, and a connection port 53, the shield 51 is installed at an external position of the connection port 53, the connection port 53 is embedded and connected with the fixed rod 52, and the shield The cover 51 has a circular structure, which can better protect the connection port 53 .

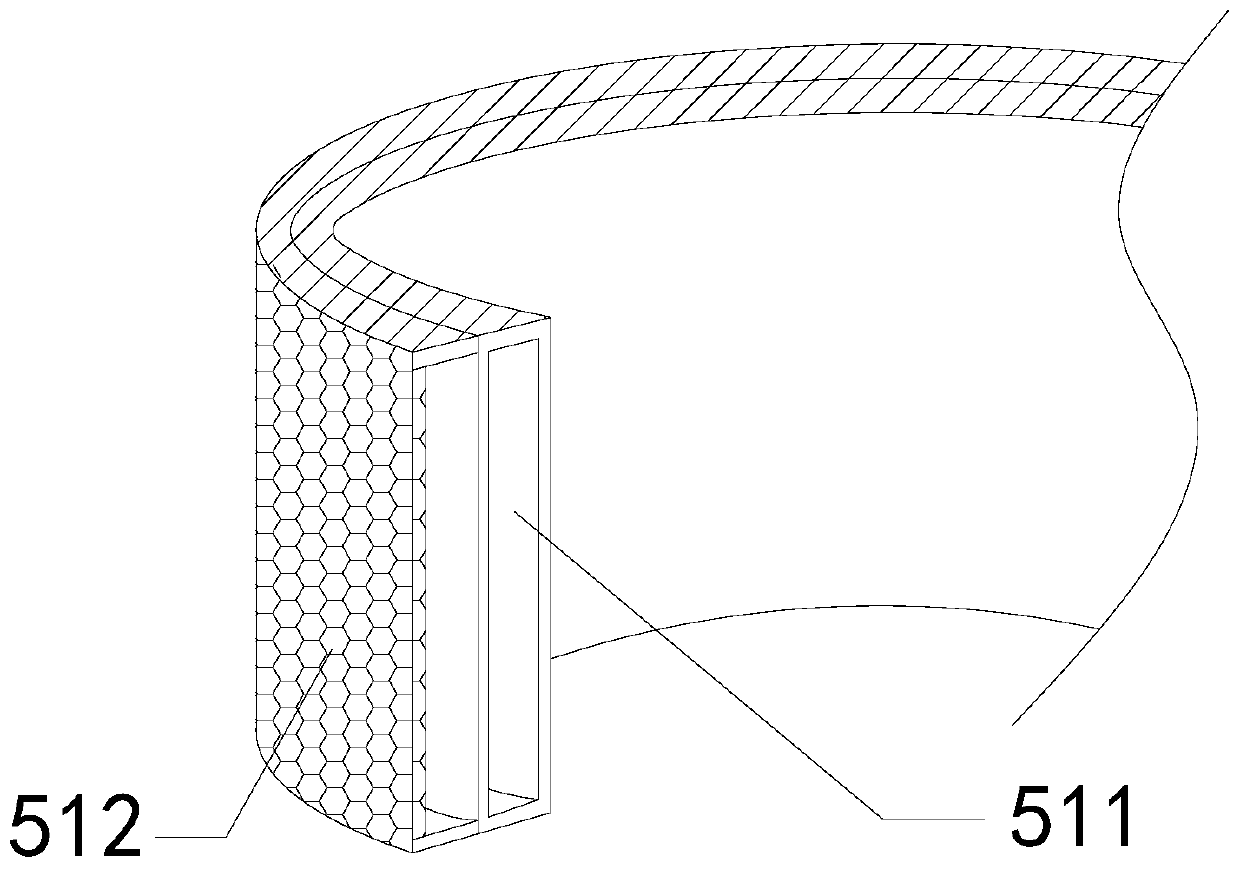

[0034] Wherein, the shield 51 includes a fixed inne...

Embodiment 2

[0042] For example Figure 8 -example Figure 10 Shown:

[0043] Wherein, the movable outer ring 512 includes a baffle c1, a clearing mechanism c2, and a through-hole plate c3, the baffle c1 is embedded and connected with the clearing mechanism c2, and the through-hole plate c3 is embedded and connected with the baffle c1. The perforated plate c3 has a porous structure, which can allow splashing sparks to enter from all angles, effectively improving the treatment effect on sparks.

[0044] Wherein, the cleaning mechanism c2 includes a brush head c21 and a fixed pipe c22, the brush head c21 is embedded and connected with the fixed pipe c22, and the fixed pipe c22 is installed at the rear end of the brush head c21, and the brush head c21 adopts a hardness The higher polyurethane sponge is beneficial for the brush head c21 to remove welding slag.

[0045] Wherein, the fixed pipe c22 includes a housing c221, a seepage pipe c222, and a liquid receiving chamber c223, the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com