Fast quartz sand crushing device

A crushing device and quartz sand technology, applied in grain processing, etc., can solve problems such as low crushing efficiency, adaptive adjustment in structural design, and practical defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

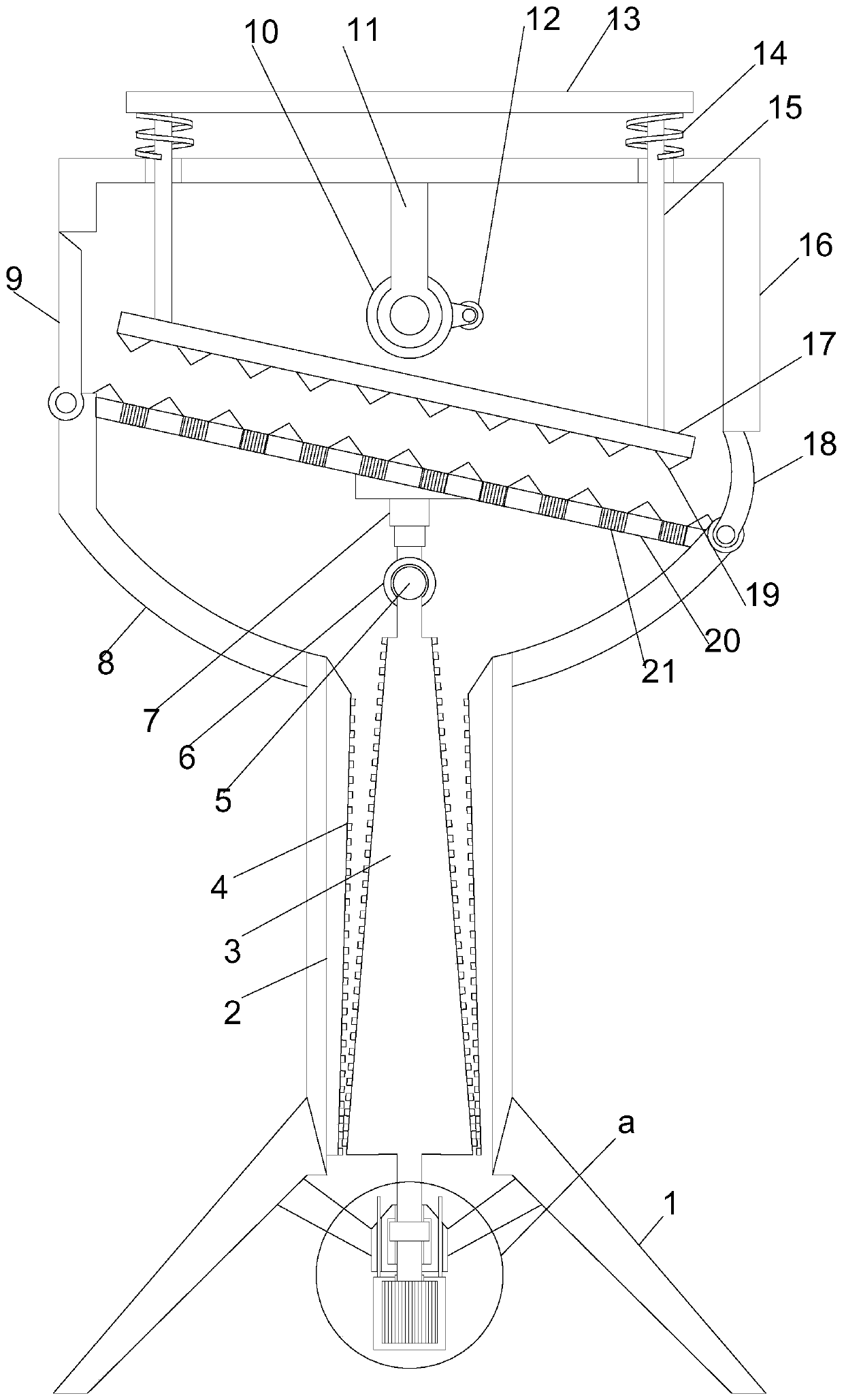

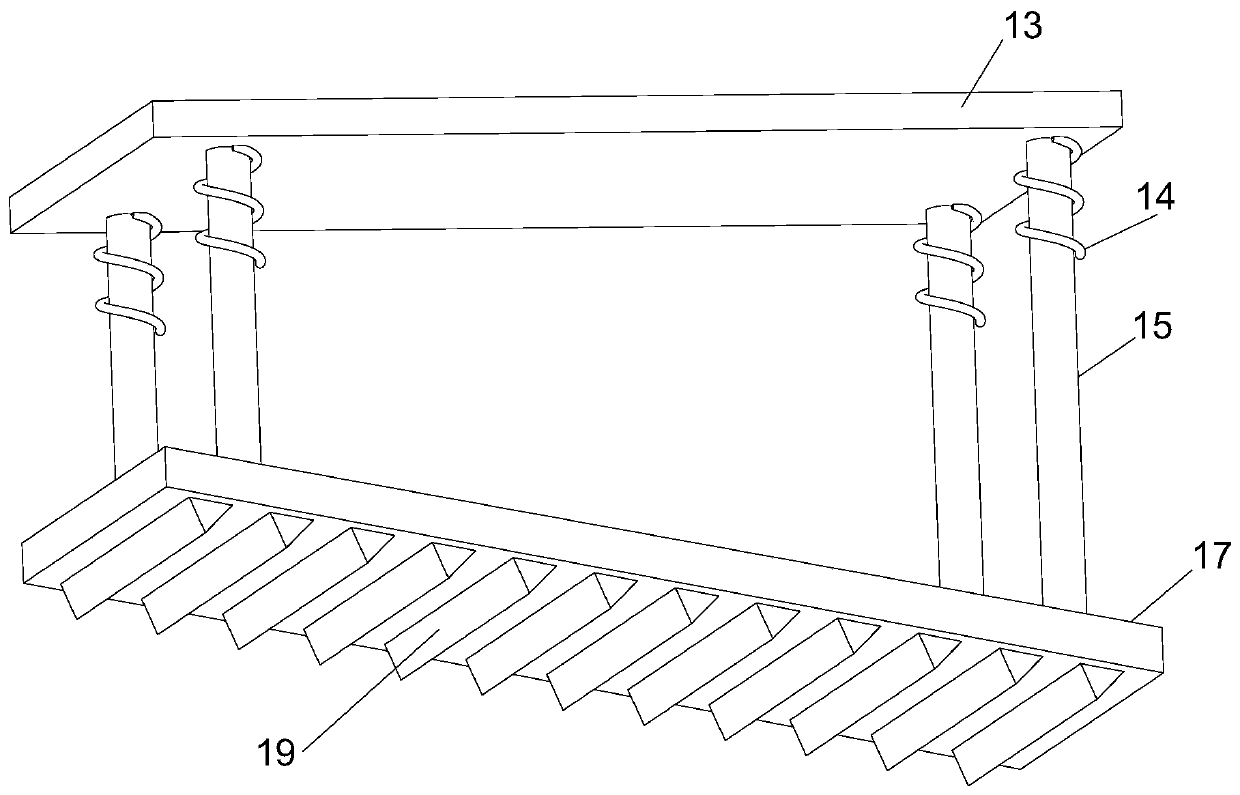

[0023] see Figure 1~3 , in an embodiment of the present invention, a quick crushing device for quartz sand includes a vertically arranged support installation cylinder 2, a number of support installation columns 1 are arranged at equal angles on the lower edge of the support installation cylinder 2, and the vertical support installation cylinder 2 is vertically The operation installation cylinder 16 is directly arranged, and the lower end of the operation installation cylinder 16 is provided with an arc surface installation cylinder 8, and the lower end of the arc surface installation cylinder 8 is connected with the upper end of the support installation cylinder 2, and the inside of the operation installation cylinder 16 is provided with a multi-hole guide. The material plate 20, the operation installation cylinder 16 is provided with the feed gate 9 in cooperation with the left end of the porous material guide plate 20, the arc surface installation cylinder 8 is provided wit...

Embodiment 2

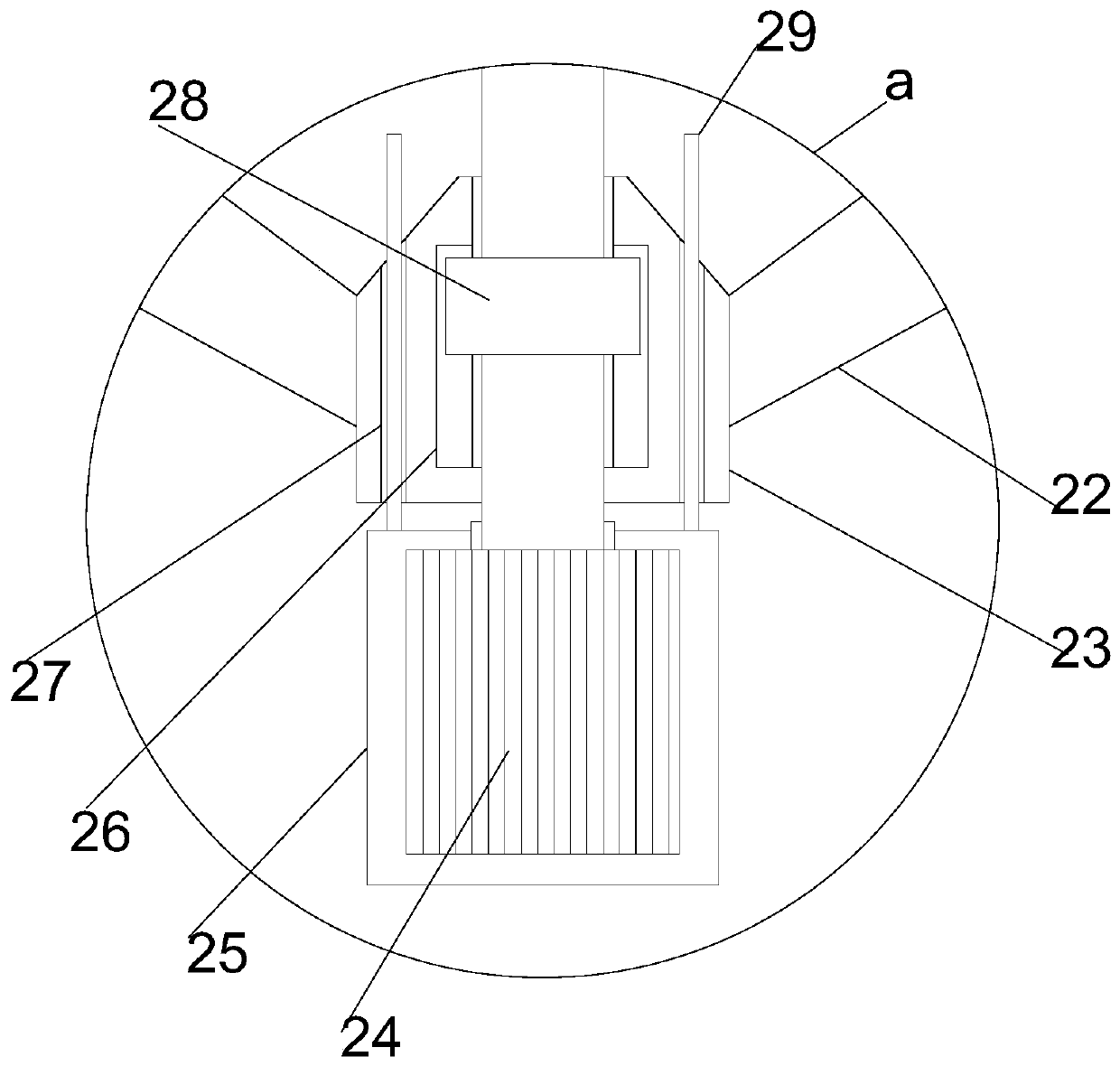

[0026] On the basis of Embodiment 1, when the driving motor 24 and the rotating conical surface crushing column 3 are adjusted up and down, the guide limit shaft 28 cooperates with the guide groove 26, and the limit guide post 29 cooperates with the limit guide hole 27 to realize stable guide displacement. , and the limit rotation sleeve 6 cooperates with the limit rotation block 5, so that rotation and crushing can still be realized during the displacement process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com