Photocatalysis device and method for removing malodorous gas by using photocatalysis device

A malodorous gas and photocatalytic technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as impact on contact, TiO2 deactivation, and low treatment efficiency of sulfur-containing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

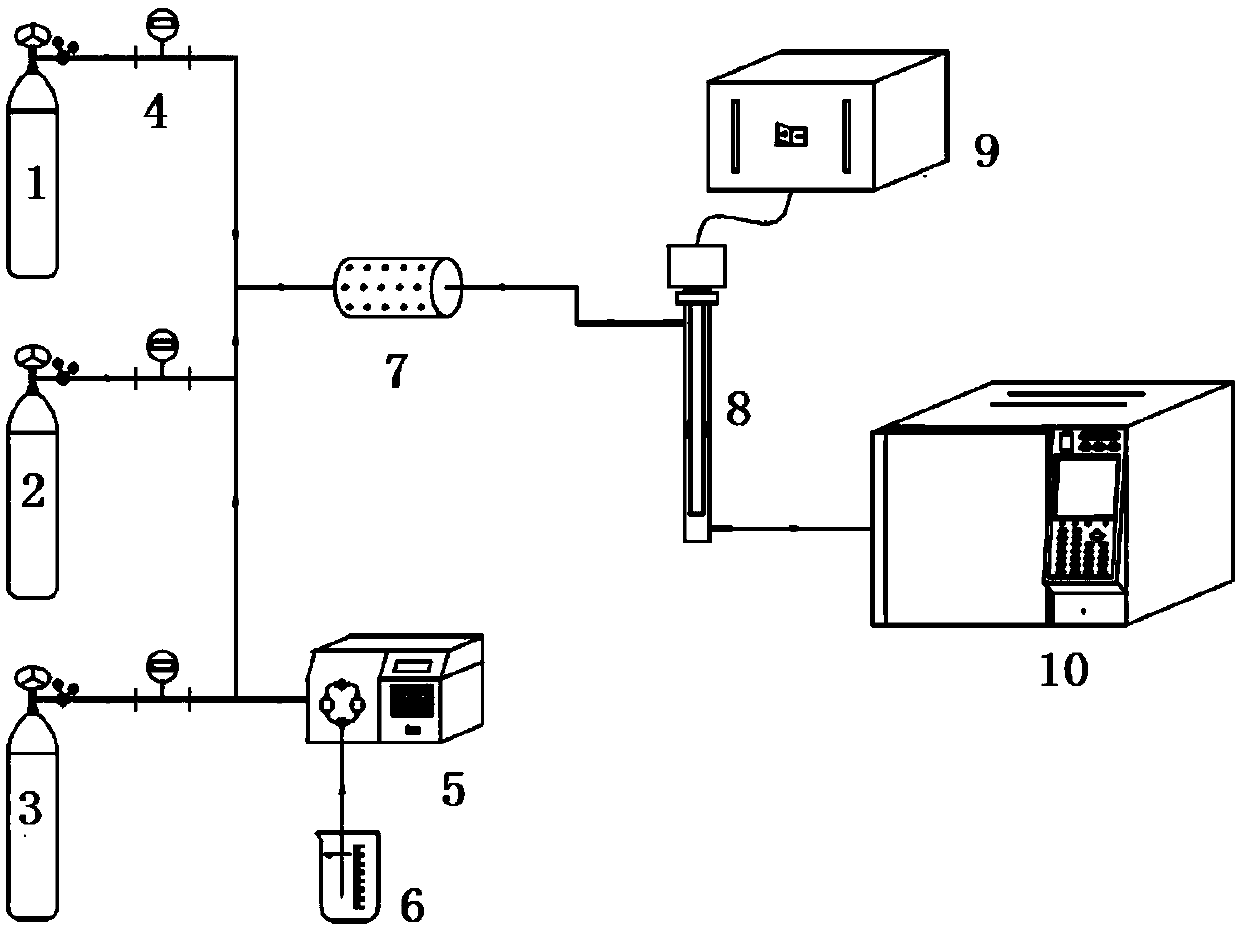

Method used

Image

Examples

preparation example Construction

[0049] In the present invention, the preparation method of described hydrophobic photocatalyst comprises the following steps:

[0050] Step 1: activating the molecular sieve;

[0051] The molecular sieve is a zeolite molecular sieve, preferably a ZSM-5 zeolite molecular sieve in the present invention, more preferably a HZSM-5 zeolite molecular sieve, and the silicon-aluminum ratio of the HZSM-5 type molecular sieve is 20-40, and the specific surface area is 300 ~400m 2 / g, relative crystallinity ≥ 90%;

[0052] The inventors found that before use, the molecular sieve is activated, preferably the HZSM-5 molecular sieve is subjected to high-temperature activation treatment to remove impurities such as carbon deposits; so that the performance of the final hydrophobic photocatalyst is better;

[0053] Activation at 400-800°C, the preferred activation temperature is 400-600°C;

[0054] The high-temperature activation temperature of the HZSM-5 molecular sieve is 400-600°C, more p...

Embodiment 1

[0110] The HZSM-5 molecular sieve was activated under an air atmosphere at 500°C for 4 hours to remove impurities and carbon deposits in the molecular sieve to obtain an activated HZSM-5 molecular sieve.

Embodiment 2

[0112] Take 5g of HZSM-5 obtained in Example 1 and ethanol at a mass ratio of 1:15 and vigorously stir for 0.5h to fully disperse the HZSM-5 molecular sieve in the ethanol solution, and then press the mass ratio of HZSM-5 to 1:5 Add 1 g of butyl titanate, continue to stir for 1 h, make the butyl titanate fully contact with the molecular sieve, then slowly add 20 mL of deionized water dropwise, and stir vigorously for 1 h to fully hydrolyze the butyl titanate, and carry out the Ultrasonic 0.5h.

[0113] Next, the obtained solution was filtered, put into a drying oven and dried overnight at 80° C., and finally the dried sample was put into a muffle furnace and calcined at 550° C. for 4 hours. The obtained powder is compressed into tablets and sieved to obtain granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com