Production process for steamed cake

A production process and cake steaming technology, which is applied in the field of cake steaming production process, can solve the problems of low production efficiency, waste of materials, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

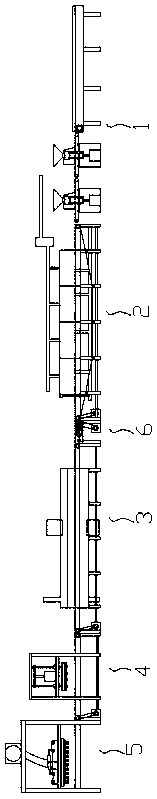

[0081] Please refer to Figure 1~19 Shown, a kind of production technology of steamed cake comprises the following steps:

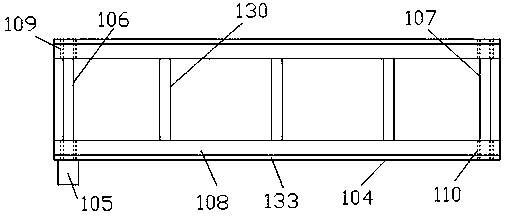

[0082] (1) Place the cake mold tray on the conveying line, and place a paper tray into each cavity of the mold tray;

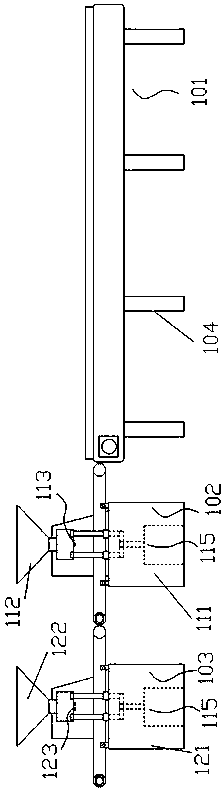

[0083] (2) Transport the prepared cake batter into the cake batter injection molding device 1, and inject the cake batter into each paper holder on the mold plate through the cake batter injection molding device 1;

[0084] (3) Send the mold plate with the cake paste into the tunnel cake steaming oven 2, and heat the cake paste through the high-temperature steam in the furnace to form a steamed cake; when the mold plate reaches the tunnel cake steam oven 2, At the outlet end, the mold plate is vibrated by the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com