Automated analyzer and automated analyzer control method

一种自动分析装置、控制方法的技术,应用在分析材料、测量装置、通过光学手段进行材料分析等方向,能够解决脱离调整范围等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

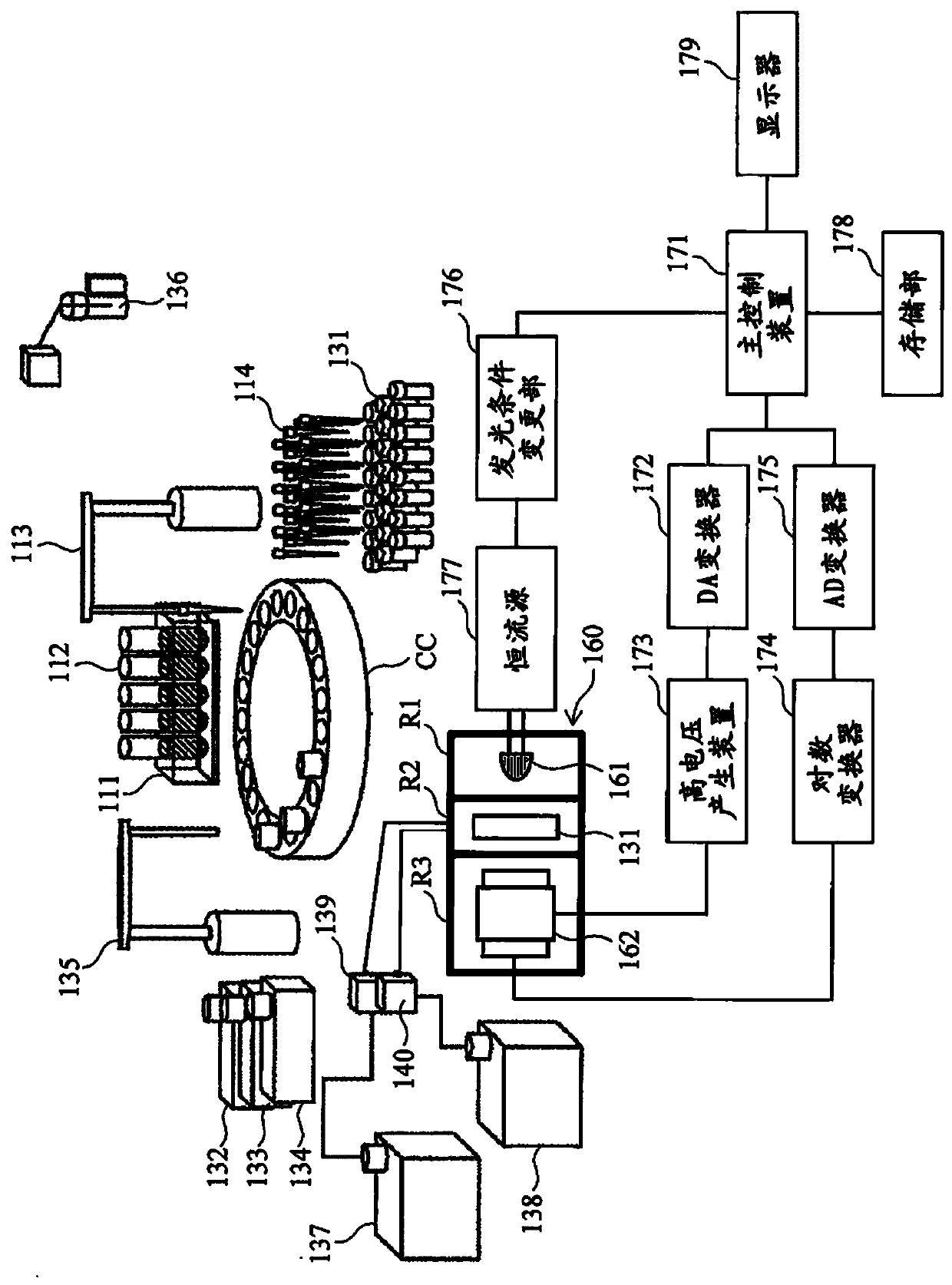

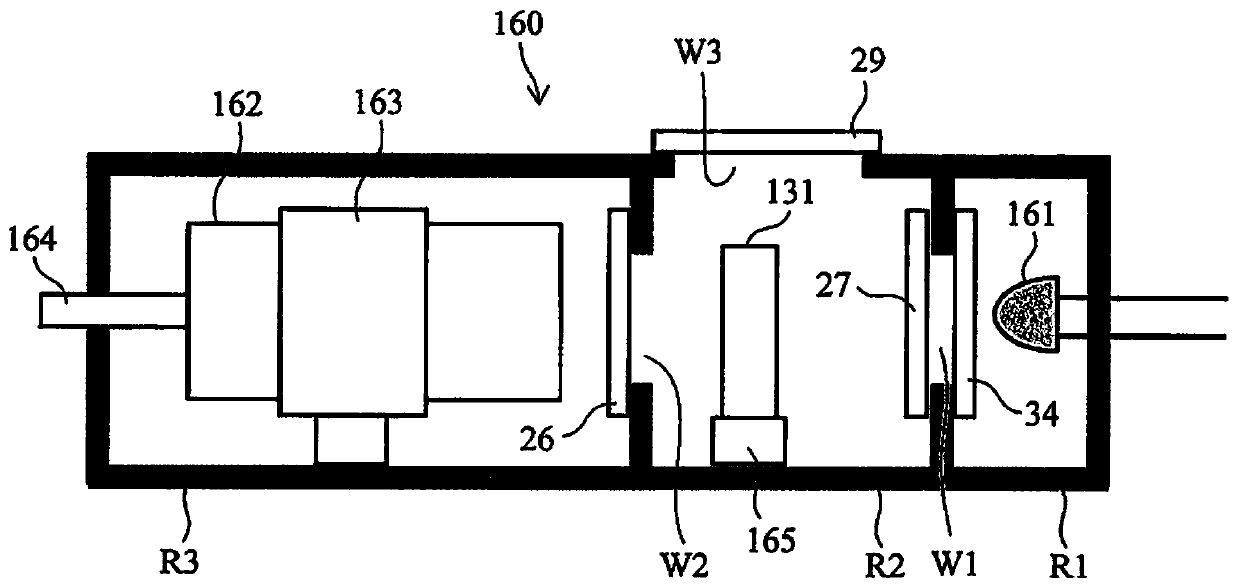

[0029] First, refer to figure 1 The automatic analyzer of the first embodiment of the present invention will be described.

[0030] In this first embodiment, the following automatic analyzer will be described as an example, that is, a photomultiplier tube is used as a detector, and a chemiluminescence method using an acridinium ester as a luminescent label is used in the detection part, but the acridinium ester is only is an example, not limited to.

[0031] figure 1 It is a schematic diagram showing the overall configuration of the automatic analyzer of the first embodiment. This apparatus includes a container rack 111 , and is configured such that a test material container 112 can be mounted on the container rack 111 . In addition, this device includes a sampling mechanism 113 that sucks the test material in the test material container 112 through the sampling sheet 114 . The container racks 111 are sequentially transported by a transport mechanism not shown to a positio...

no. 2 approach

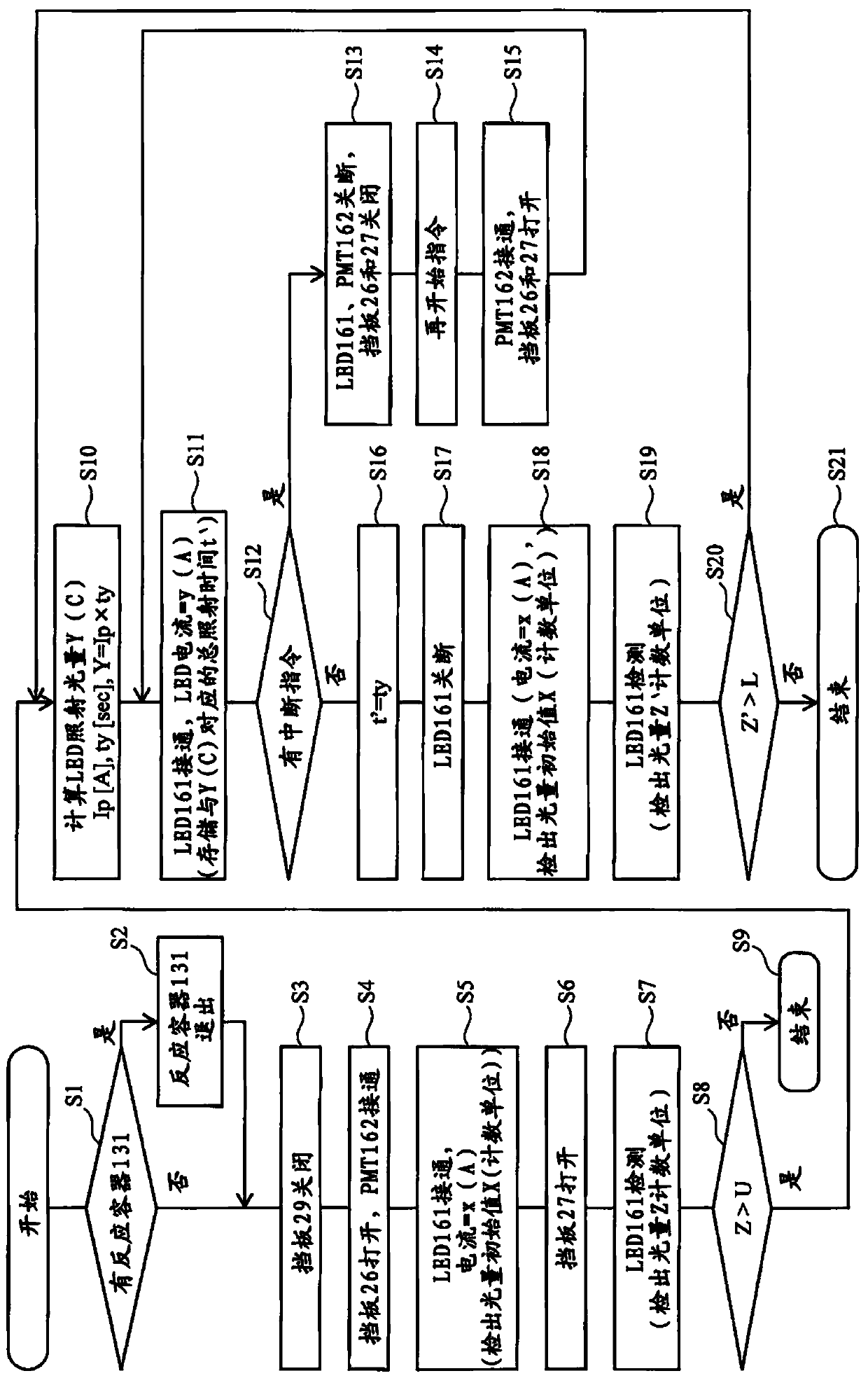

[0086] Next, refer to Image 6 and Figure 7 The automatic analyzer of the second embodiment will be described. The appearance of the structure of the device is the same as that of the first embodiment ( figure 1 ) are the same, so repeated explanations are omitted. However, the operation of controlling the sensitivity of the photomultiplier tube 162 in the second embodiment is different from that in the first embodiment. Specifically, this second embodiment differs from the first embodiment in that, in addition to controlling the sensitivity of the photomultiplier tube 162 by irradiating control light, it also performs control by correcting an electric signal. Control of the sensitivity of the photomultiplier tube 162.

[0087] Image 6 It is a flowchart showing the procedure of inspecting the photomultiplier tube 162 and controlling the sensitivity as necessary in the automatic analyzer of the second embodiment. in addition, Figure 7 It is a conceptual diagram (graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com