Composition for cooling and lubricating a drive system of a vehicle

A technology of composition and mixture, which is applied in the direction of lubricating composition, base material, thickener, etc., can solve the problems of unsatisfactory cooling potential and unguaranteed lubrication level, etc., and achieve good cooling performance, easy preparation, and good stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] Preparation of lubricating compositions (CL) according to the invention and comparative compositions (CC)

[0166] The components of the composition were mixed according to the properties and amounts (expressed in mass percent) of the products shown in Table 1 below.

[0167]

[0168] (1) by Evonik under the trade name Comb polymethacrylate polymer sold in 3-200;

[0169] (2) Trade name by Infineum 261 is a star hydrogenated copolymer of styrene, butadiene and isoprene.

[0170] Table 1

[0171] The properties of the compositions thus prepared are shown in Table 2.

[0172] CL1 CL2 CC1 KV100-ISO 3104 (mm 2 .s -1 ) *

6.10 5.95 5.90

[0173] *Kinematic viscosity measured at 100°C according to standard ISO3104

[0174] Table 2

Embodiment 2

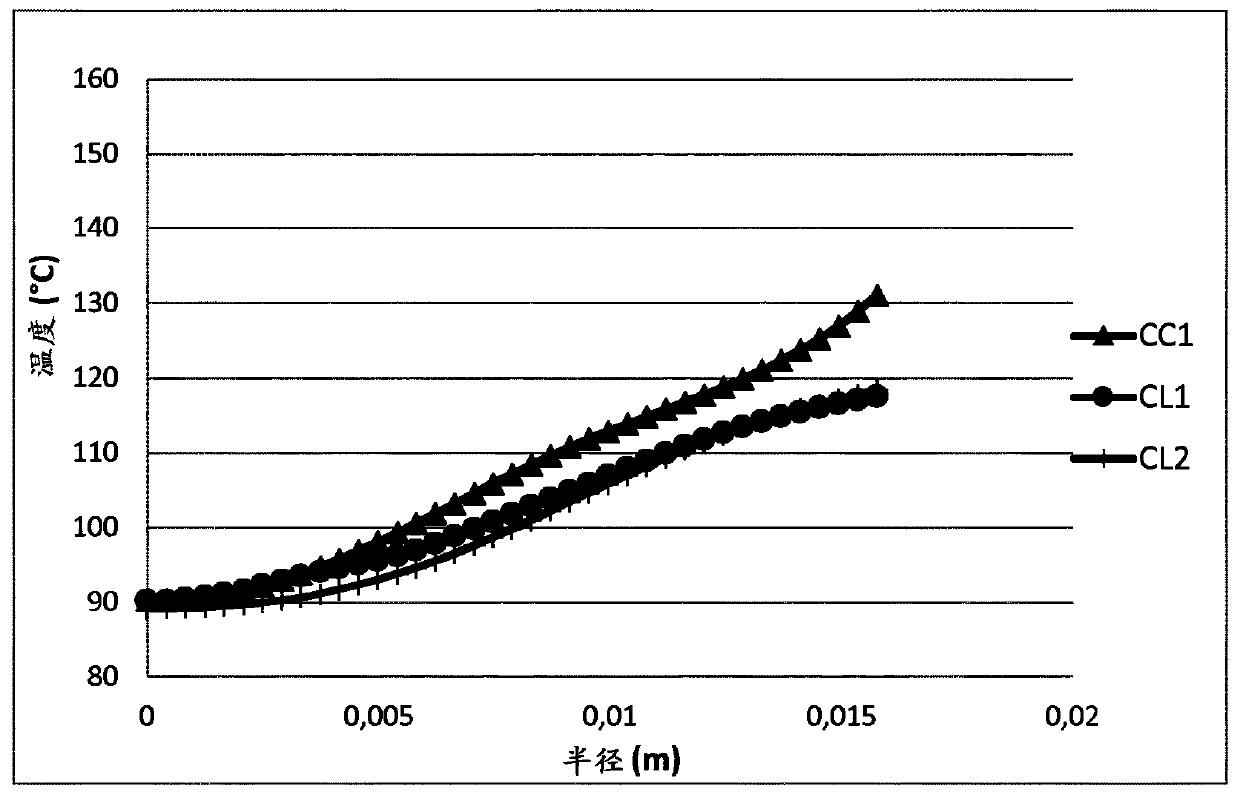

[0176] Measurement of thermal properties of compositions according to the invention

[0177] One way to measure the thermal properties of a fluid is to measure the heat transfer coefficient (heat transfer per unit surface area and temperature) of the fluid. Fluids with higher heat transfer coefficients have better cooling properties.

[0178] Tests to measure the heat transfer coefficients of each of the compositions described in Table 1 were performed.

[0179] The principle of the test consists in injecting an oil jet by means of a nozzle perpendicular to the induction heated metal plate. A thermal imaging camera placed above the plate records the temperature profile during oil injection. The average heat transfer coefficient of the composition can be calculated from the temperature change on this plate.

[0180] Various parameters can be varied, notably the temperature of the plates, the size of the nozzles and the pressure at which the oil is ejected. Measurements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com