Production method of button cell without welding traces and prepared button cell

A technology of a button battery and a production method, which is applied to the equipment for manufacturing a primary battery, a cylindrical shell battery/battery, a primary battery, etc. Bulge and other problems, to achieve the effect of good connection stability, easy detection, and avoidance of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

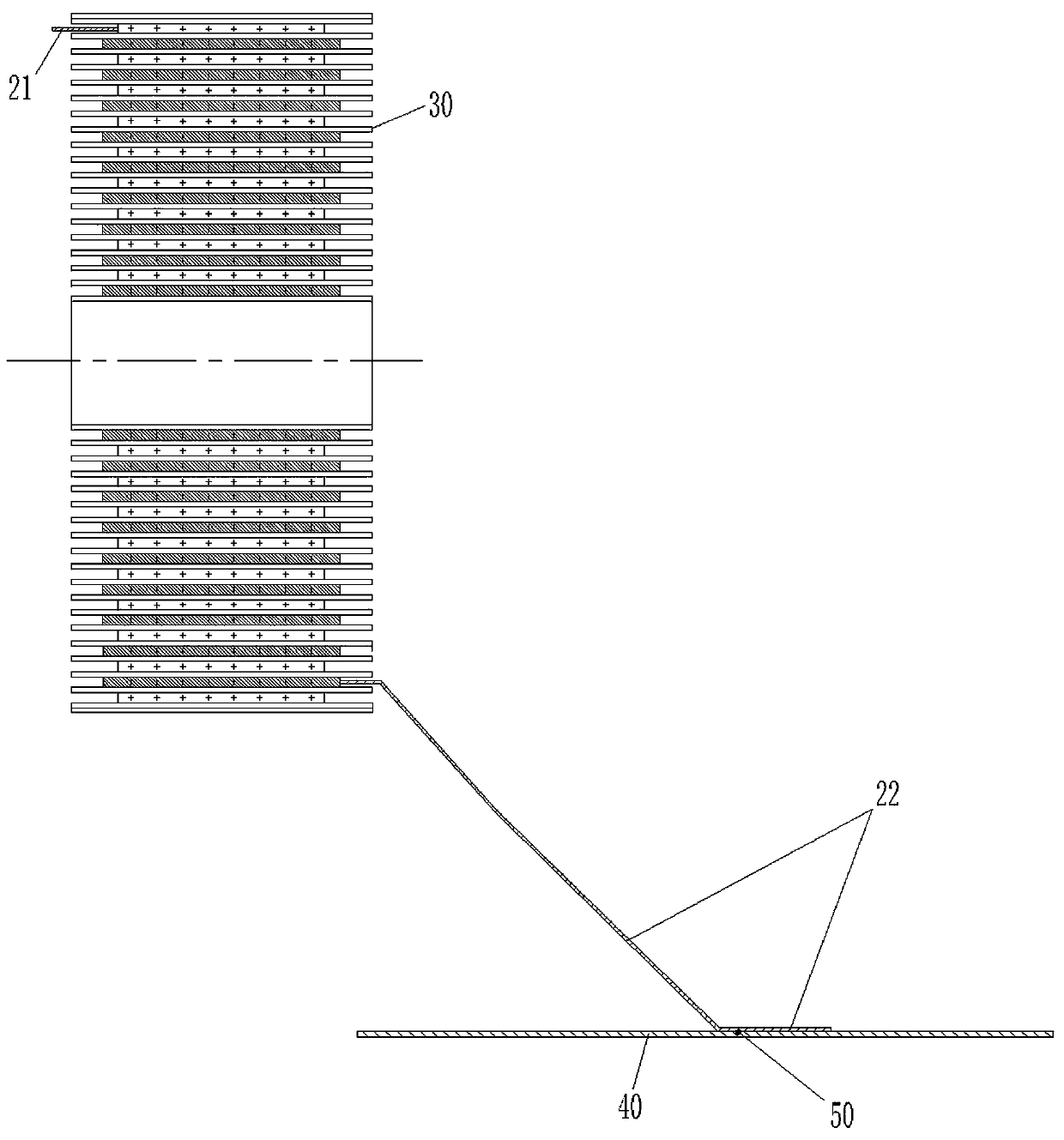

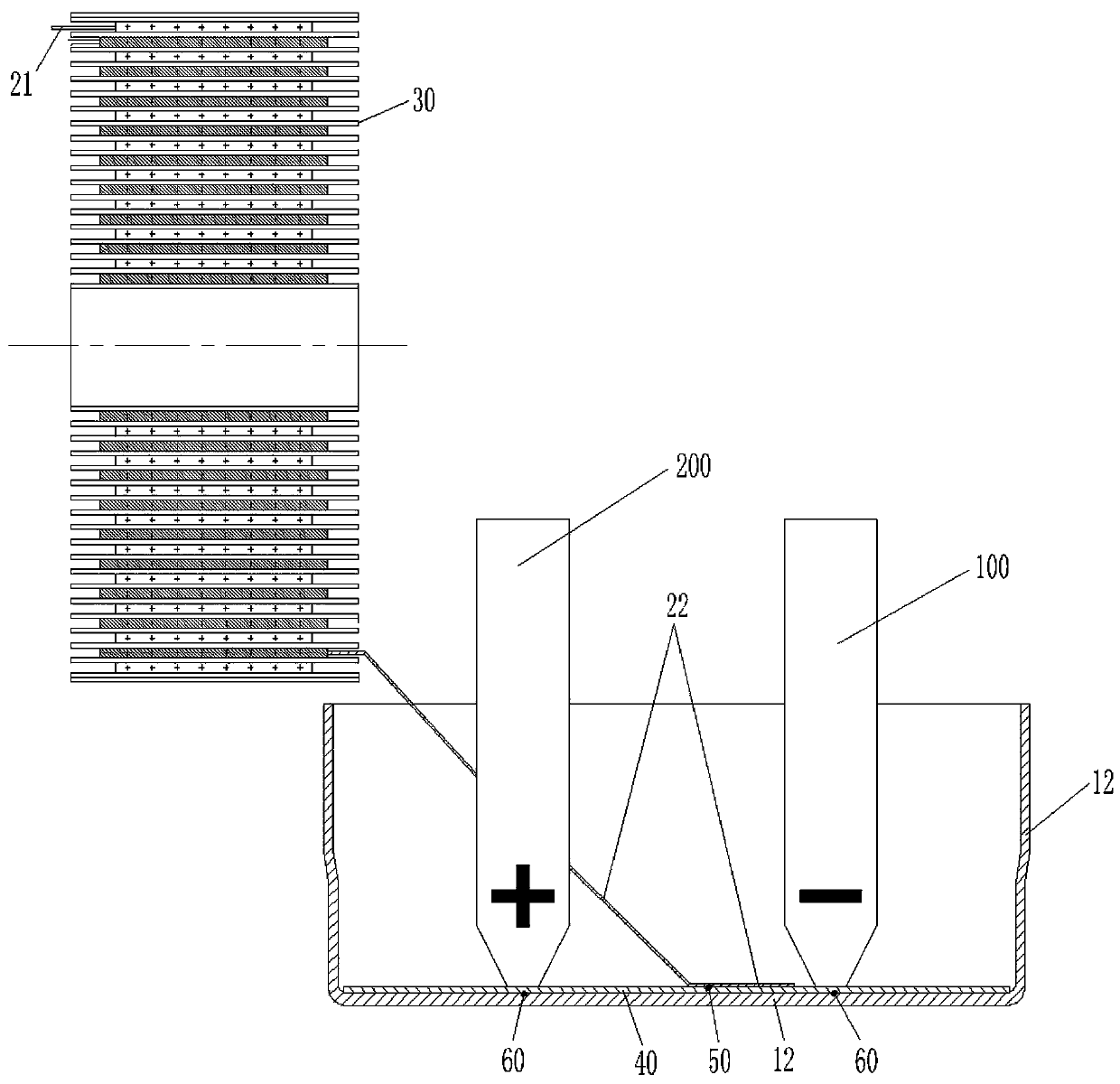

[0032] combine Figure 1~Figure 4 , a production method of a button battery without welding traces, the button battery includes a positive electrode case 11, a negative electrode case 12, an insulating sealing ring 70 and an electric core 30, the positive electrode case 11 and the negative electrode case 12 are cup-shaped, and the positive electrode case 11 and the negative electrode case 12 are cup-shaped. Negative pole case 12 can open up and down relative to buckle to form cylindrical button cell casing; Described positive pole case 11 and negative pole case 12 partially overlap in vertical direction, and the opening end wall 111 of described positive pole case 11 is positioned at the opening end wall of negative pole case 12 121 inside, there is a gap between the opening end wall 111 of the positive electrode casing 11 and the opening end wall 121 of the negative electrode casing 12, and the insulating sealing ring 70 fills the gap to electrically isolate the positive elect...

Embodiment 2

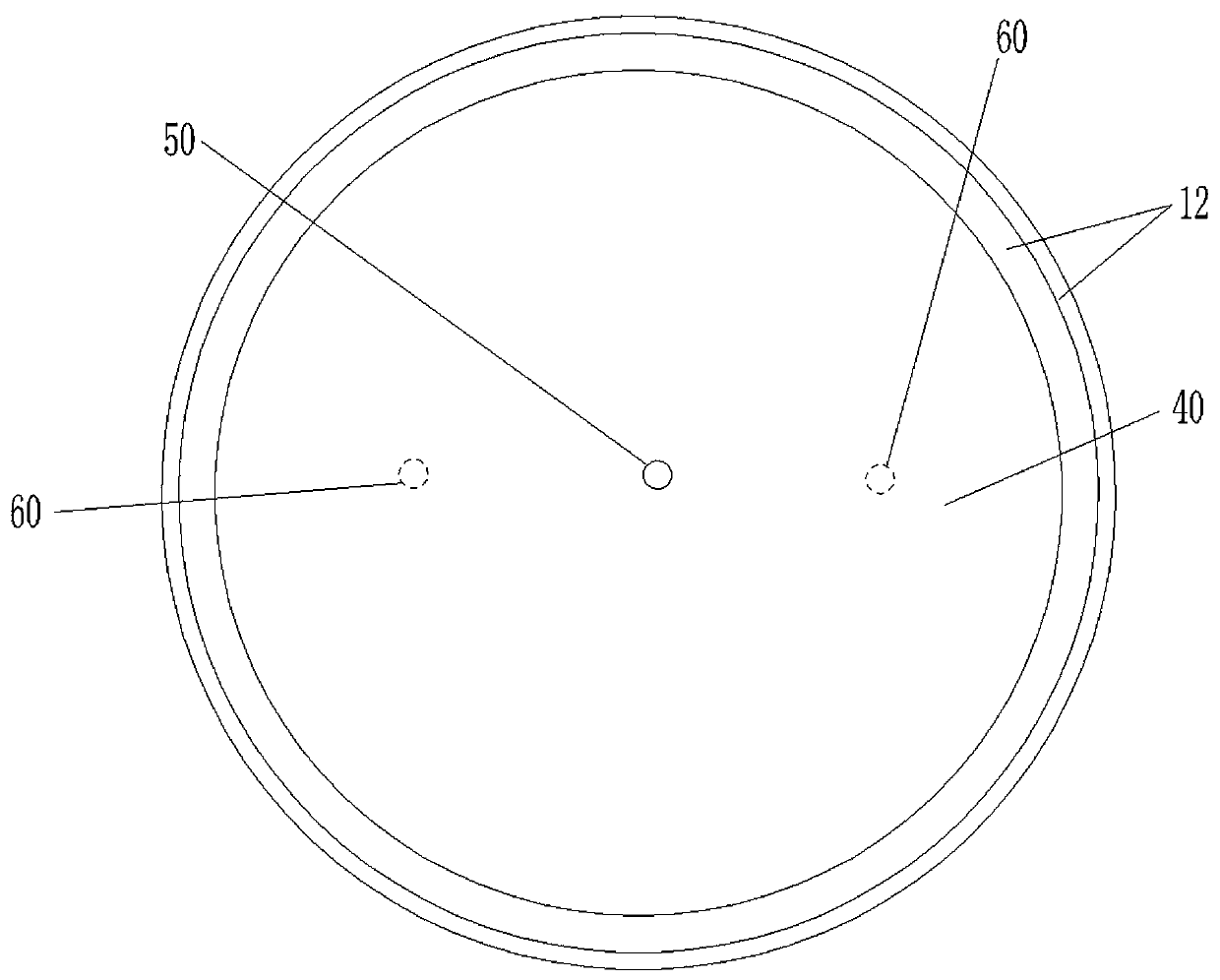

[0040] like Image 6 As shown, the difference between the production method of the button battery without welding traces in Example 2 and the production method of the button battery without welding traces in Embodiment 1 is that step S2 is continuously carried out in the welding method between the negative electrode tab 22 and the negative electrode shell 12 2 times, 2 pairs of second welding spots 60 are formed between the metal sheet 40 and the negative electrode casing 12, and there are two welding positions overlapped in the welding positions of the metal sheet 40 and the negative electrode casing 12 in different sub-steps S2, and the remaining steps are all Same as Example 1.

[0041] like Image 6 As shown, the button battery without welding marks according to embodiment 2 is different from the button battery without welding marks in embodiment 1 in that: the number of second welding spots 60 is 2 pairs, and the second welding spots of different pairs There are two sec...

Embodiment 3

[0043] like Figure 7 As shown, the difference between the production method of the button battery without welding traces in Example 3 and the production method of the button battery without welding traces in Embodiment 1 is that step S2 is continuously carried out in the welding method between the negative electrode tab 22 and the negative electrode case 12 3 times, 3 pairs of second welding spots 60 were formed between the metal sheet 40 and the negative electrode casing 12, and the welding positions of the metal sheet 40 and the negative electrode casing 12 in different steps S2 did not overlap, and the remaining steps were all the same as in Example 1 same.

[0044] like Figure 7 As shown, the button battery without welding marks according to embodiment 3 is different from the button battery without welding marks in embodiment 1 in that: the number of second welding spots 60 is 3 pairs, and the second welding spots of different pairs 60 do not overlap, and all the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com