Magnetic powder particle surface all-dimensional film-attaching anti-oxidation method

A particle surface and all-round technology, which is applied in the manufacture of permanent magnets, inductors/transformers/magnets, electrical components, etc., can solve the problems of reduced service life of magnetic powder, contact with atomized solution, and defects in the oxidation resistance of magnetic powder. , to achieve uniform thickness, avoid waste, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

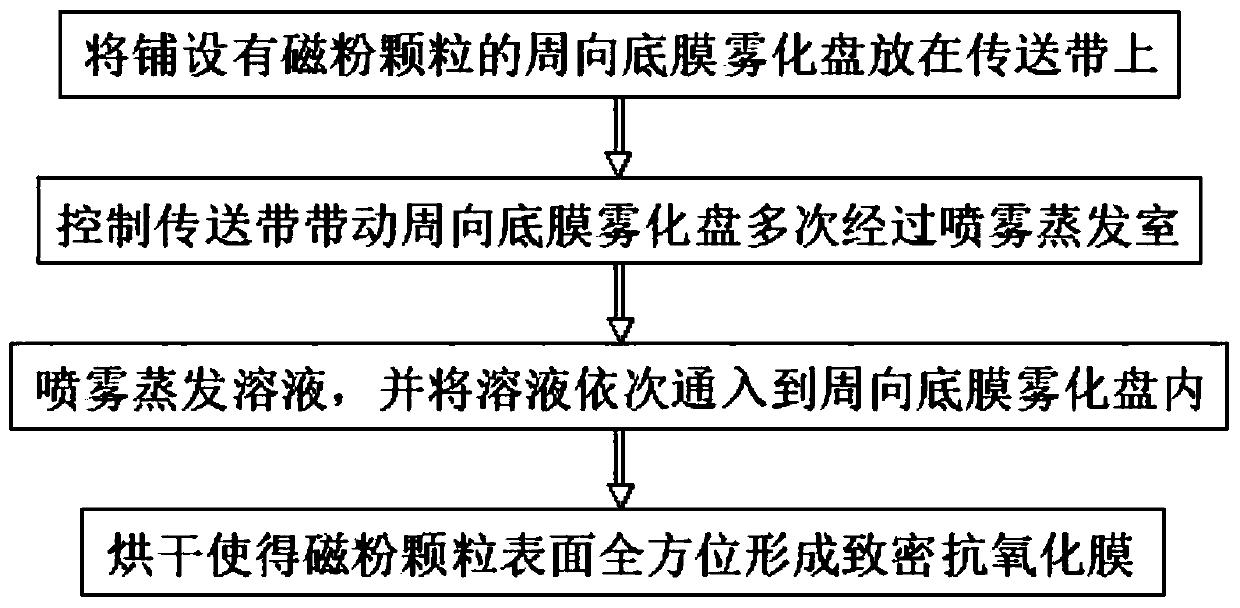

[0047] see Figure 1-2 , a method for all-round film-attached anti-oxidation on the surface of magnetic powder particles, comprising the following steps:

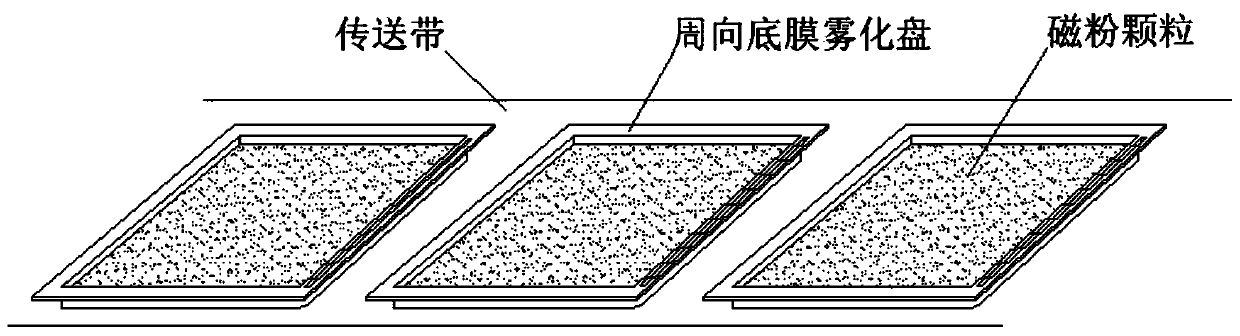

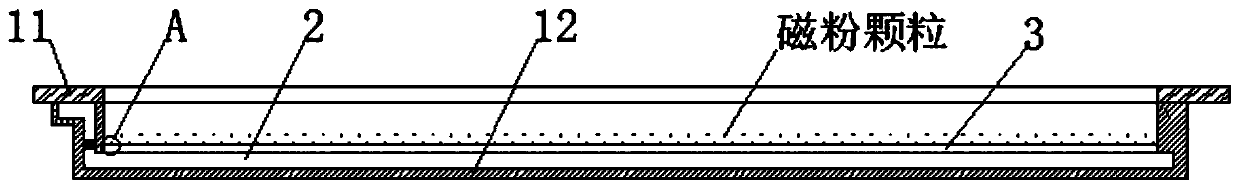

[0048] S1. First lay the magnetic powder particles on the circumferential bottom film atomizing disc, and place the circumferential bottom film atomizing disc on the conveyor belt in turn;

[0049] S2. Control the conveyor belt to drive the circumferential bottom film atomizing disc to pass through the spray evaporation chamber several times;

[0050] S3. When passing through the spray evaporation chamber for many times, spray and evaporate phosphoric acid, sodium bisulfite solution and sodium hydroxide solution respectively, and simultaneously pass the above solutions into the circumferential bottom film atomization disk in sequence;

[0051] S4, electrifying the bottom of the atomizing plate with the circumferential bottom film to dry the magnetic powder, so that a dense anti-oxidation film is formed on the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com