Method for determining laser defocusing amount in femtosecond laser polishing process of optical element

A femtosecond laser and optical element technology, applied in laser welding equipment, complex mathematical operations, manufacturing tools, etc., can solve the problems of high cost, poor accuracy and low efficiency of polishing defocus, and achieve high efficiency and high accuracy. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

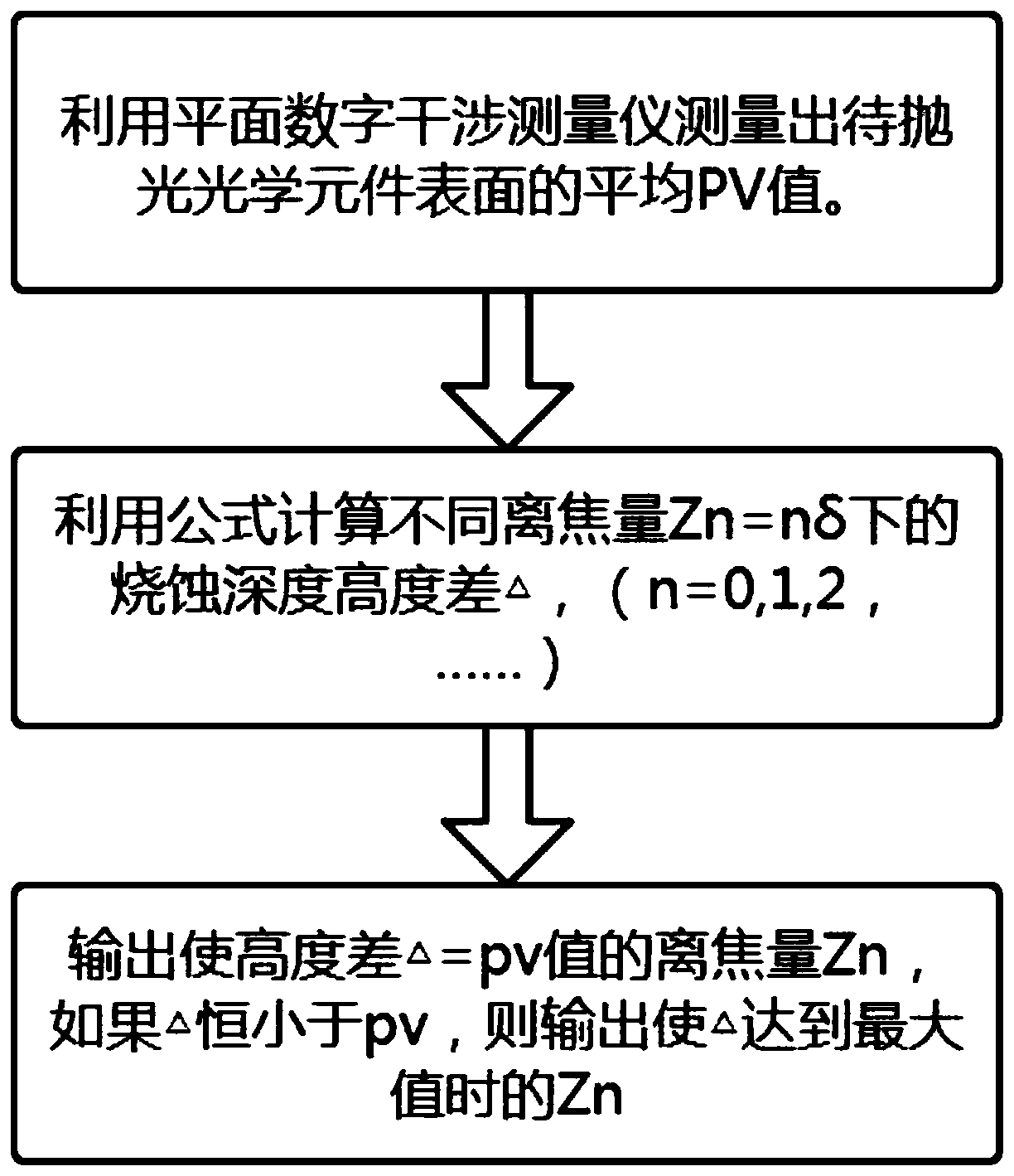

[0033] see figure 1 , a method for determining the amount of laser defocus in the process of femtosecond laser polishing optical components, a method for determining the amount of laser defocus in the process of femtosecond laser polishing optical components, comprising the following steps:

[0034] A. Use the femtosecond laser to output the laser wavelength λ(m), and the focus spot radius r(m) to calculate the Rayleigh length ZR(m) of the beam,

[0035] B. Use the output pulse energy F(J) of the laser to focus the spot radius r(um) and the defocus amount Z(um) to calculate the energy density F`(J / um) when the laser reaches the surface of the material 2 ),

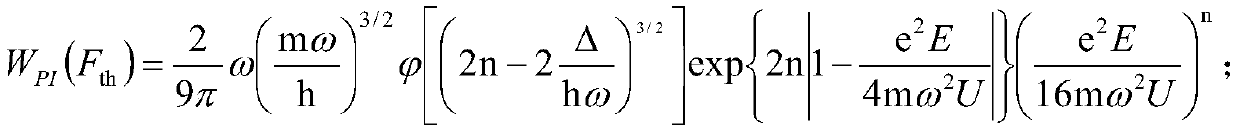

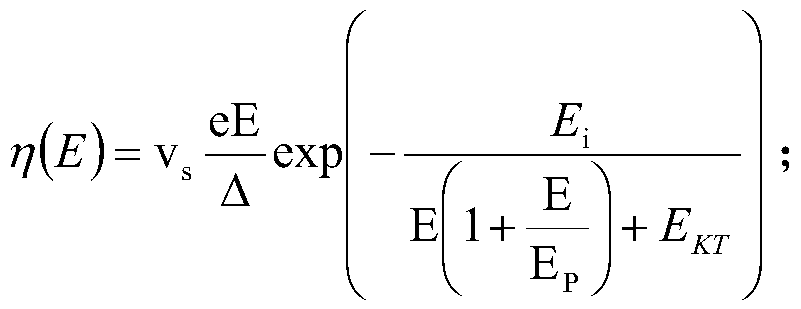

[0036] C. Calculate the ablation depth L (m) on the surface of the energy material by using the femtosecond laser ablation rate mathematical model, where the ablation rate mathematical model is:

[0037]

[0038] In the formula, L is the ablation depth; h is Planck's constant; ω is the laser frequency; τ is the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com