Integrated sampling calibration constant-pressure alkalization measurement device

A measuring device and integrated technology, applied in the direction of measuring device, material electrochemical variables, sampling, etc., can solve the problems of easy failure of instruments, easy aging of diffusion tubes, poor alkalizing effect, etc., and reduce flow failures and maintenance costs. , Increase reliable performance and service life, the effect of simple flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

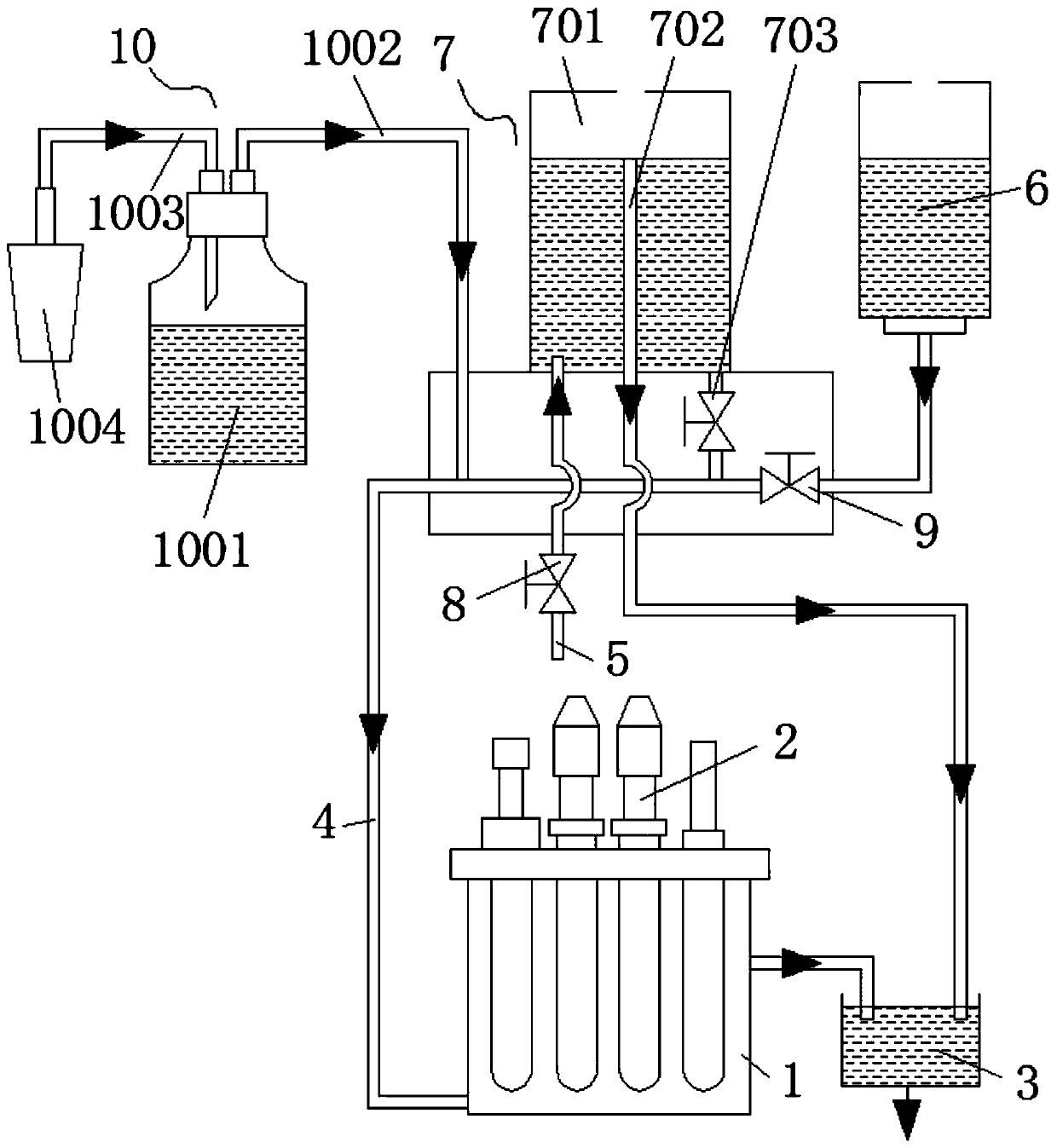

[0017] see figure 1 , an integrated sampling calibration constant pressure alkalization measuring device, comprising a measuring tank 1, the measuring tank 1 is provided with a measuring assembly 2, the outlet of the measuring tank 1 is connected to a sewage tank 3 through a pipeline, and the measuring tank 1 The inlet is connected to an alkalization solution pipe 4, and the alkalinization solution pipe 4 is sequentially connected to a water sample injection pipe 5 and a calibration liquid bottle 6, and the water sample injection pipe 5 is connected to the alkalinization solution pipe. 4 is provided with a constant pressure sampling assembly 7; a sampling valve 8 is provided on the water sample sampling tube 5 to adjust the flow rate of the inlet water sample; a calibration liquid valve 9 is provided at the outlet of the calibration liquid bottle 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com