Boiler scale thickness monitoring device and method

A technology of thickness monitoring and boiler scale, which is applied in the boiler field, can solve problems such as potential safety hazards, explosions, boiler scale monitoring, etc., and achieve the effects of easy maintenance and replacement, high measurement accuracy, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

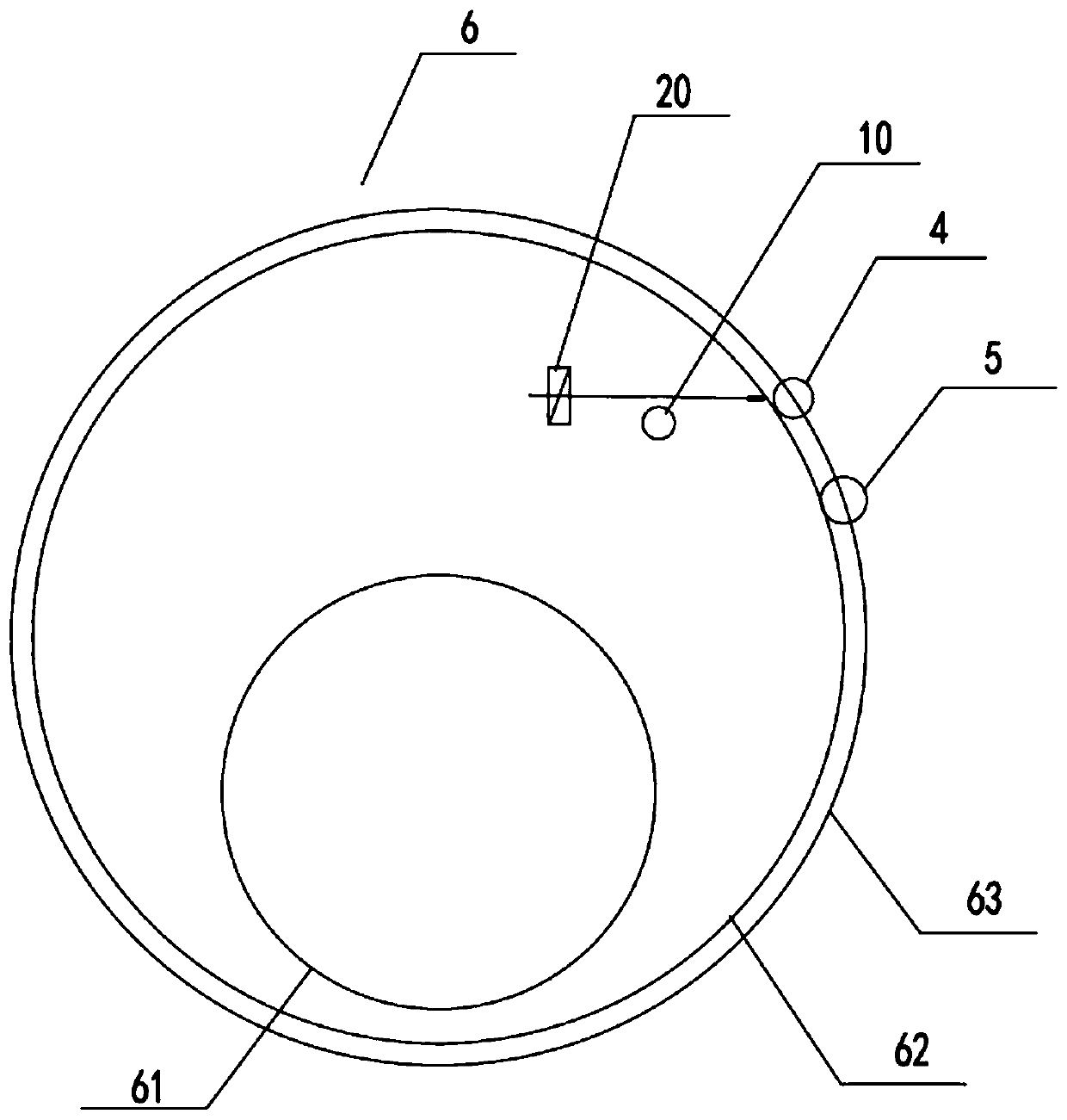

[0036] Such as figure 1 As shown, the boiler scale monitoring device includes a temperature sensor, a descaling device and a control device. The descaling device is installed inside the boiler to remove the scale at a certain position in the boiler. The descaling area should be slightly larger than the wall thickness of the boiler at this position. A furnace is arranged inside the boiler, and the boiler wall is divided into an inner wall and an outer wall. The temperature sensor is installed on the outer wall of the boiler, including a first temperature sensor and a second temperature sensor. The first temperature sensor is installed on the outer wall corresponding to the descaling position of the descaling device, and the second temperature sensor is installed on the outer wall near the descaling position. on the wall. The second temperature sensor should be separated from the first temperature sensor by a certain distance to ensure that the scale in the boiler correspondin...

Embodiment 2

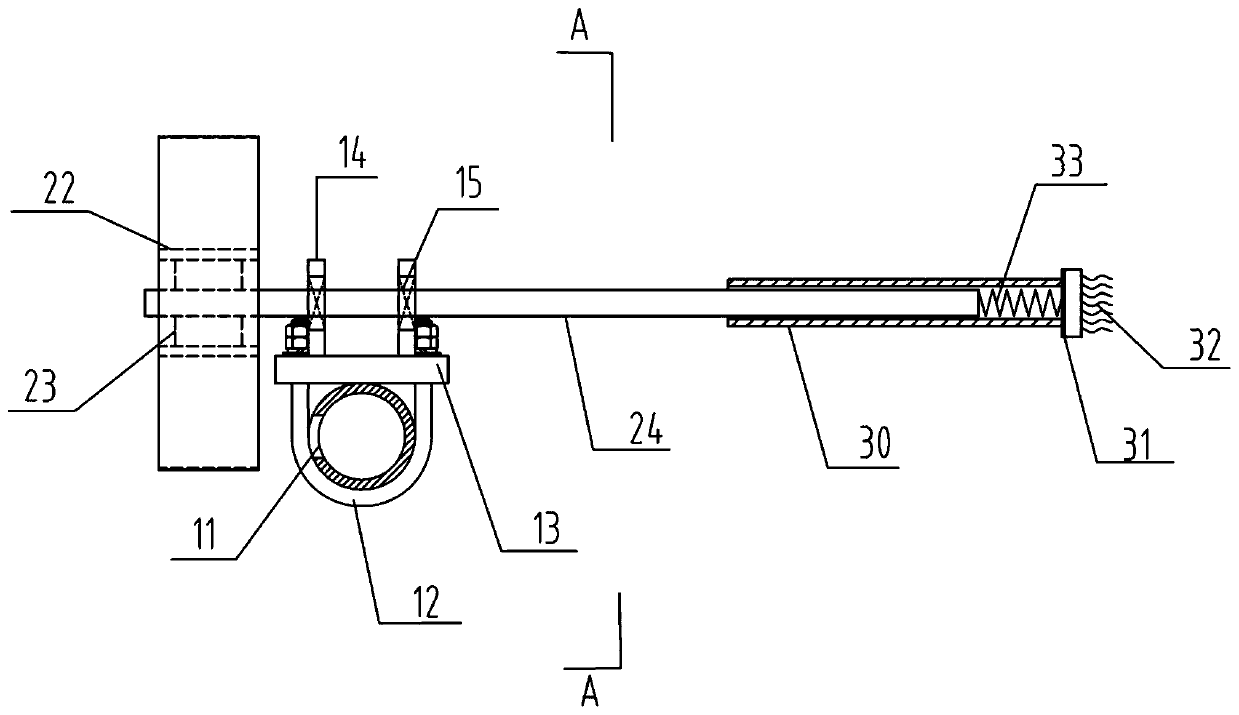

[0053] Such as Figure 8-9 As shown, the descaling device of this embodiment includes a water supply pipe, a turbine device and a cleaning device. The turbine device is installed on the water supply pipe, and the cleaning device is installed on the turbine device. The turbine device in this embodiment includes turbine blades, a transmission shaft and a driven shaft. The turbine blades are straight blades, one end of the transmission shaft is connected with the turbine blades, and the other end is equipped with gears. A gear is installed at one end of the driven shaft, and the gear is vertically driven with the gear on the drive shaft. The other end of the driven shaft is equipped with a cleaning device. The cleaning device in this embodiment is the same as that in Embodiment 1, and will not be repeated here. In order to ensure the stable installation of the turbine device on the water supply pipe, a pair of U-shaped bolts are set on the water supply pipe, and a bottom plate...

Embodiment 3

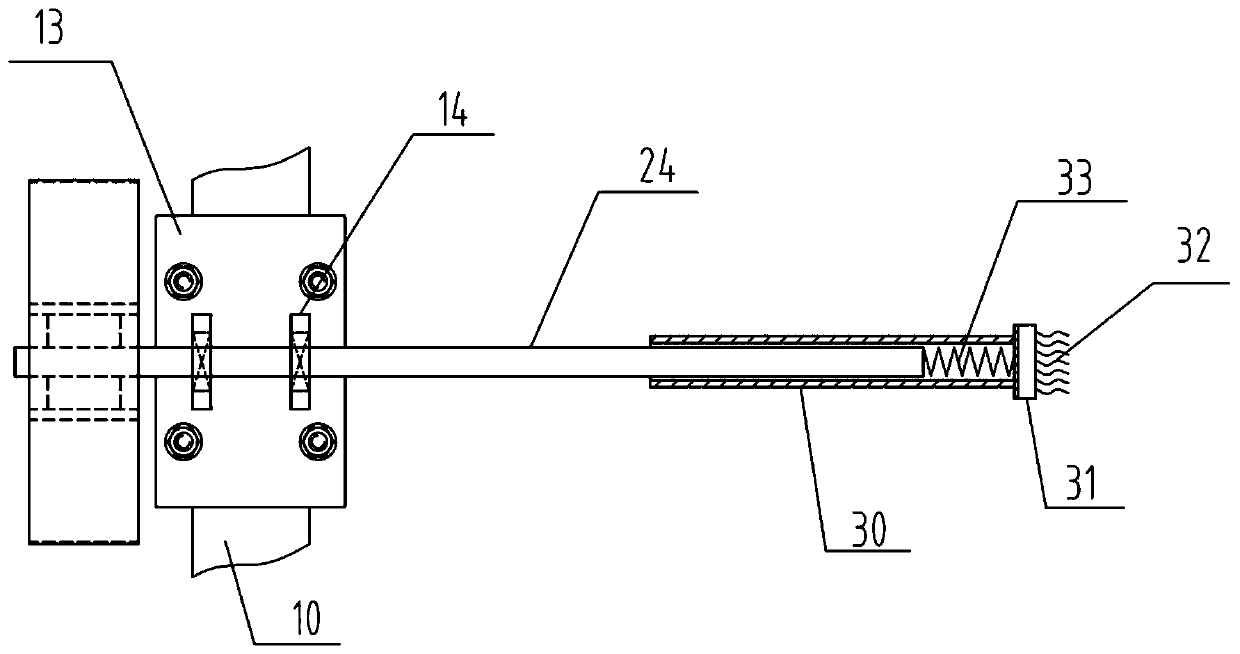

[0056] Such as Figure 10-11 As shown, the descaling device of this embodiment includes a water supply pipe, a turbine device and a cleaning device. The turbine device includes turbine blades, a drive shaft and a driven shaft. The turbine blades are installed inside the water supply pipe, and the blades are straight blades. In order to install the turbine blades into the water supply pipe, it is necessary to modify the original water supply pipe of the boiler to form a cavity capable of accommodating the turbine blades. When water enters the water supply pipe, the water flow directly washes the turbine blades and drives the turbine blades to rotate. The transmission shaft passes through the water supply pipe and is connected with the first bearing arranged on the pipe wall of the water supply pipe. The transmission shaft is vertically connected with the driven shaft and driven by gears. Two third bearing plates are welded on the wall surface of the outer pipe of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com