Retractable cleaning device for copper pipes of condenser

A technology for cleaning devices and condensers, used in cleaning heat transfer devices, flushing, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

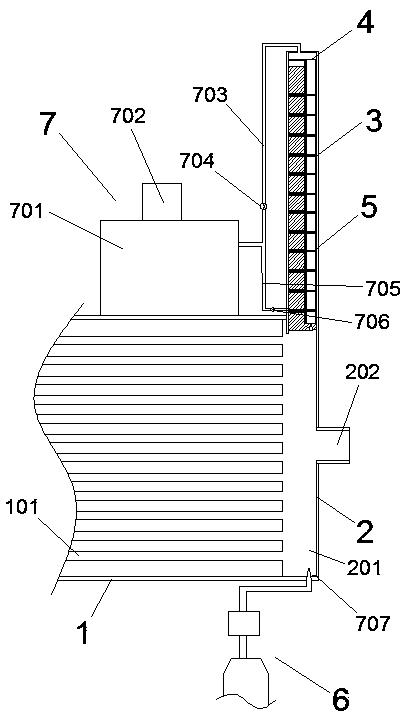

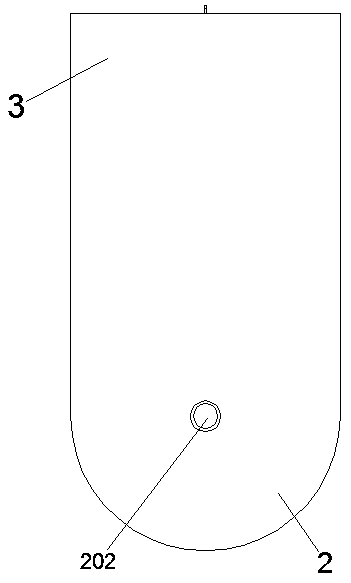

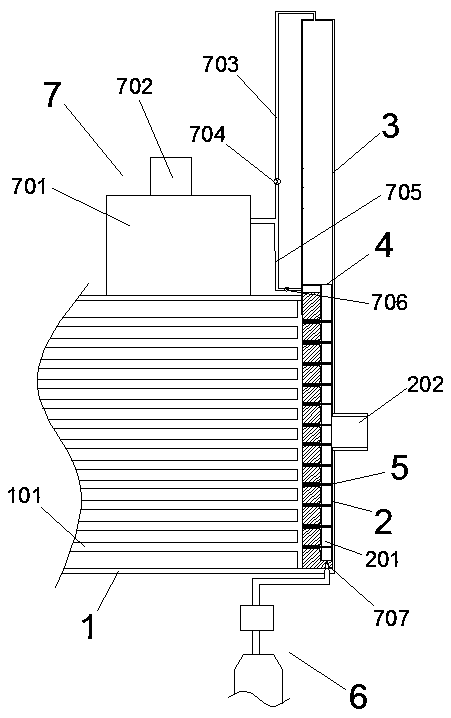

[0038] Such as Figure 1-10 As shown, a telescopic cleaning device for condenser copper pipes, the cleaning device includes a closed casing arranged at the water inlet end of the condenser 1, and the casing includes a semi-closed cavity 3 with a rectangular cross section on the upper part and The lower semicircular cover plate 2, the semicircular cover plate 2 is connected to the water inlet end of the condenser, and forms a gap between the condensation copper tube area 101 in the condenser 1 and the semicircular cover plate 2 The water cavity 201 is provided with a condensed water inlet 202 communicating with the water inlet cavity 201 on the semicircular cover plate 2; the bottom of one side of the semi-closed cavity 3 is connected to the straight edge of the semicircular cover plate 2 through an extension , the other side is connected to the outer wall of the water inlet end of the condenser 1, thereby forming a cavity communicated with the water inlet cavity 201, and a mob...

Embodiment 2

[0051] This embodiment is an improvement made on the basis of Embodiment 1, its basic structure is the same as that of Embodiment 1, and the improvements are as follows: Figure 7 As shown, the opening of the installation hole 406 towards the end of the hydraulic oil chamber 404 has a circular pit that expands around the opening, and an internal thread is provided on the inner wall of the pit, and the end of the outer sleeve 502 is fixed on a The bottom of the threaded sleeve 507, and the external thread of the outer wall of the threaded sleeve 507 forms a threaded connection with the internal thread of the inner wall of the circular pit, so as to realize the fixing of the outer sleeve 502.

Embodiment 3

[0053] This embodiment is another improvement made on the basis of embodiment 1, its basic structure is the same as that of embodiment 1, and the improvements are as follows: Figure 7-10 As shown, the center of the hollow inner tube 501 is provided with a filling part 509 extending along its axial direction, and an inner cavity 506 through which the acid cleaning agent passes is formed between the filling part 509 and the inner wall of the hollow inner tube 501 .

[0054] In this embodiment, the shape and volume of the filling part 509 can be set as required, and it is preferably cylindrical, and no matter what the shape is, in order to reduce the weight, the inside of the filling part 509 is preferably made hollow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com