Highway bridge guardrail maintenance equipment

A technology for road bridges and guardrails, which is applied in road surface cleaning, construction, cleaning methods, etc., can solve the problems of single maintenance and cleaning functions, inconvenient promotion and implementation, and high manufacturing costs, so as to improve cleaning quality, meet sustainable development requirements, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

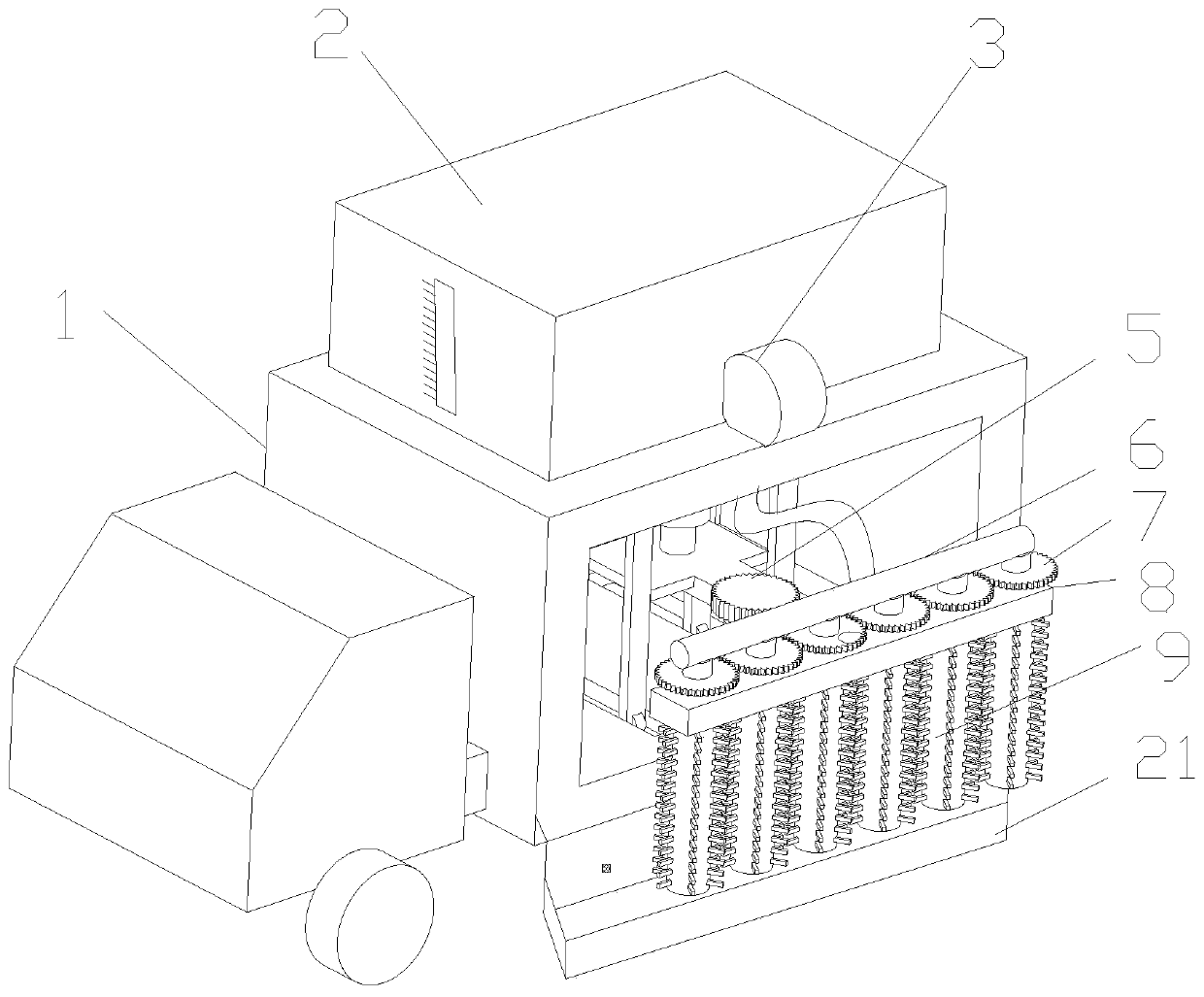

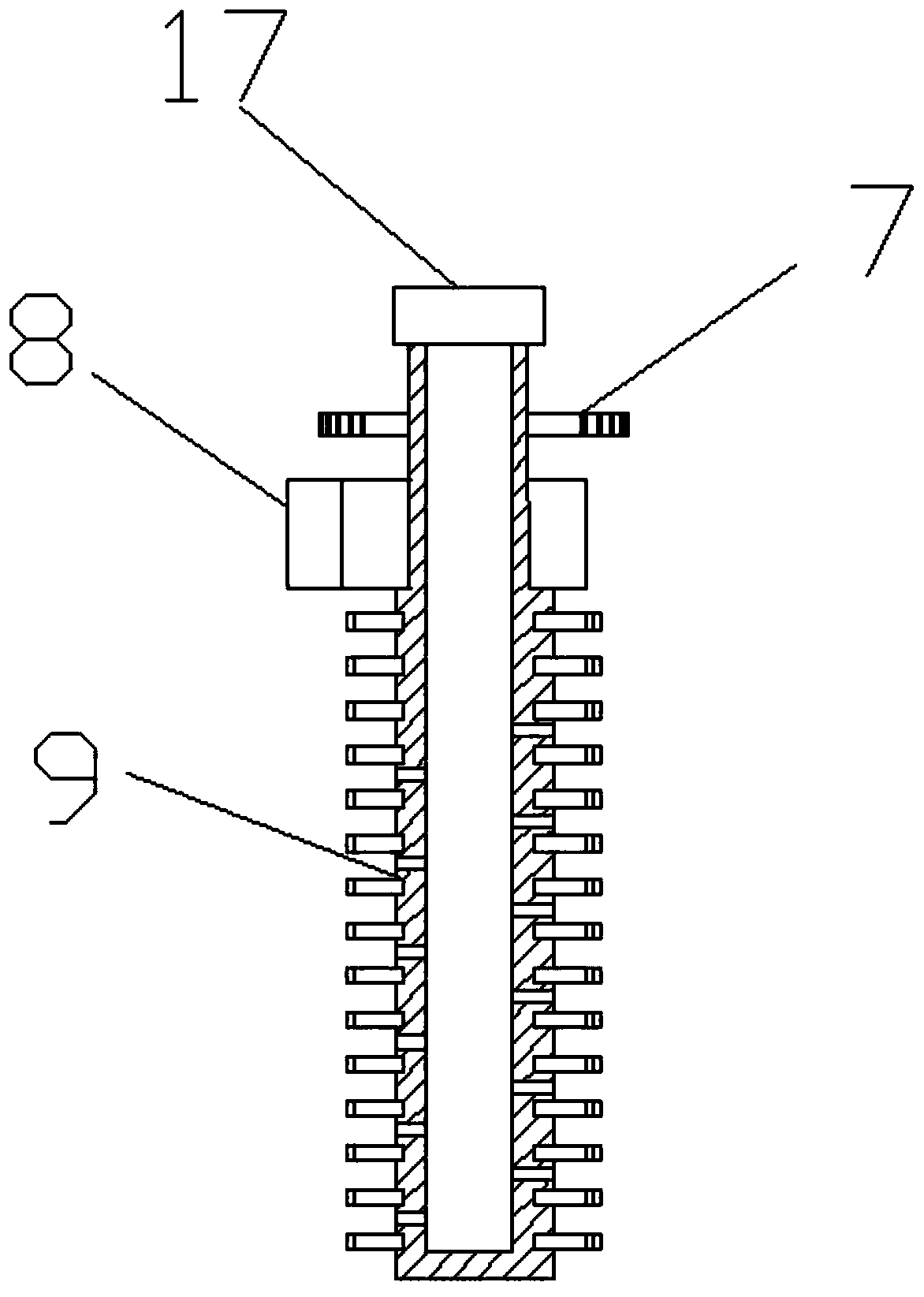

[0022] see Figure 1-4 , figure 1 It is a three-dimensional structural schematic diagram of a highway bridge guardrail maintenance equipment. figure 2 It is a schematic diagram of the front structure of a highway bridge guardrail maintenance equipment. image 3 It is a structural schematic diagram of a brush roller in a road bridge guardrail maintenance equipment. Figure 4 It is a schematic diagram of the use state of a highway bridge guardrail maintenance equipment. In the figure, a highway bridge guardrail maintenance equipment includes a carriage 1 and a brush roller 9 . The interior of the compartment 1 is slidingly provided with a translation frame 11, the inner wall of the compartment 1 is fixedly connected to one end of the first hydraulic rod 10, and the other end of the first hydraulic rod 10 is fixedly connected to the translation frame 11, and this end has a displacement sensor 20 , by monitoring the expansion and contraction of the first hydraulic rod 10, the...

Embodiment 2

[0027] On the basis of Embodiment 1, a water tank 2 is arranged on the compartment 1, and a water pump 3 is fixedly arranged on the compartment 1. The water tank 2 communicates with the water pump 3, and the water pump 3 communicates with the water distribution pipe 6 through a hose. There is a water spray hole, and the water distribution pipe 6 is rotatably connected by the shaft seal 17. Under the action of the water pump 3, the water inside the water tank 2 enters the inside of the brush roller 9 and is sprayed from the water spray hole, thereby facilitating the cleaning of the guardrail. Thereby the cleaning degree of the guardrail is improved. The water tank 2 is provided with an observation window, the setting of the observation window is convenient for observing the state of the water inside the water tank 2, and the observation window is engraved with a scale line, and the setting of the scale line is convenient for quantitatively observing the amount of water. The inb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com