Preparation process of fadeless jean fabric

A preparation process, a technology for denim fabrics, applied in dyeing, textiles and papermaking, etc., can solve the problems of large pollution discharge, dull color, poor color fastness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

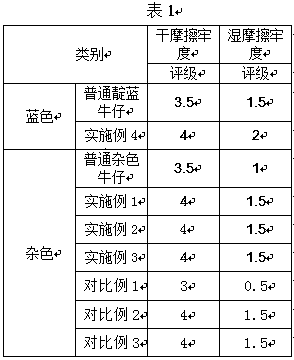

Examples

Embodiment 1

[0031] Embodiment 1 is the best embodiment of the present invention, and the present invention will be further explained below in conjunction with the embodiments.

[0032] The modifier used in the following examples is the FST IND NEW cationic modifier from Jianming Industrial (Zhuhai) Co., Ltd., the direct dye is from Jianming Industrial (Zhuhai) Co., Ltd., the dye liquor bath ratio is 1:10, and the penetrant is Yixing Zhongda Chemical Co., Ltd. The ZD-128 produced, non-foaming soaping agent, color-fixing agent and dry-wet rubbing fastness improving agent were purchased from Boxing Tongsheng Industry and Trade Co., Ltd. The model of non-foaming soaping agent is TS-XH, and the model of color-fixing agent is TS-LX, the type of dry and wet rubbing fastness improving agent is TS-890, all the water used is from Lanyan Textile's hard water softening tank, the loom used is Itema R9500 rapier, and the average hardness of EDTA titration is 50ppm.

[0033] Example 1

[0034] A prepar...

Embodiment 2

[0051] A preparation method of non-fading denim fabric, the direct dye is BROWN DIRTY C-D OVD stained brown.

[0052] The dye concentrations are as follows:

[0053] Dirty brown 20g / L

[0054] Yuanming Powder 20g / L

[0055] Sodium carbonate 5g / L

[0056] Penetrant 7g / L

[0057] 1) Cooking: Cook the pure cotton yarn at 60℃ and 0.4psi pressure for 20s, in which cationic modifier is added to the cooking water to make the concentration of the cationic modifier to be 50g / L;

[0058] 2) Washing: After washing three tanks at room temperature, it floats through five empty tanks and enters the direct dye bar for dyeing;

[0059] 3) Dyeing: dyeing twice at 100℃, 22s each time;

[0060] 4) Soaping: enter the soaping pool, wherein the concentration of non-foaming soaping agent is 5g / L;

[0061] 5) Washing and color fixing: After two washings, it is put into a color fixing agent with a concentration of 40g / L, and the color is fixed twice for 20s each time;

[0062] 6) Drying: finally ...

Embodiment 3

[0067] A preparation method of non-fading denim fabric, the direct dyes are selected from Venetian red, dark blue and blackberry.

[0068] The dye concentrations are as follows:

[0069] Venice Red 3.75g / L

[0070] Dark blue 3.375 g / L

[0071] Blackberry 0.375 g / L

[0072] Yuanming Powder 7.5g / L

[0073] Sodium carbonate 5g / L

[0074] Penetrant 3g / L

[0075] 1) Scouring: scouring the viscose yarn at 60℃ and 0.4psi pressure for 20s, in which the cationic modifier is added to the scouring water to make the concentration of the cationic modifier 30g / L;

[0076] 2) Washing: After washing three tanks at room temperature, it floats through five empty tanks and enters the direct dye bar for dyeing;

[0077] 3) Dyeing: dyeing twice at 90℃, 22s each time;

[0078] 4) Soaping: enter the soaping pool, wherein the concentration of non-foaming soaping agent is 5g / L;

[0079] 5) Washing and color fixing: After two washings, it is put into a color fixing agent with a concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com