Sludge treatment method of alkali treatment coupled single-chamber microbial electrochemical system

A technology of microbial electrochemistry and treatment method, which is applied in the field of sludge treatment, can solve the problems that the remaining sludge cannot be completely decomposed, and achieve the effect of increasing the concentration of organic matter and improving the degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

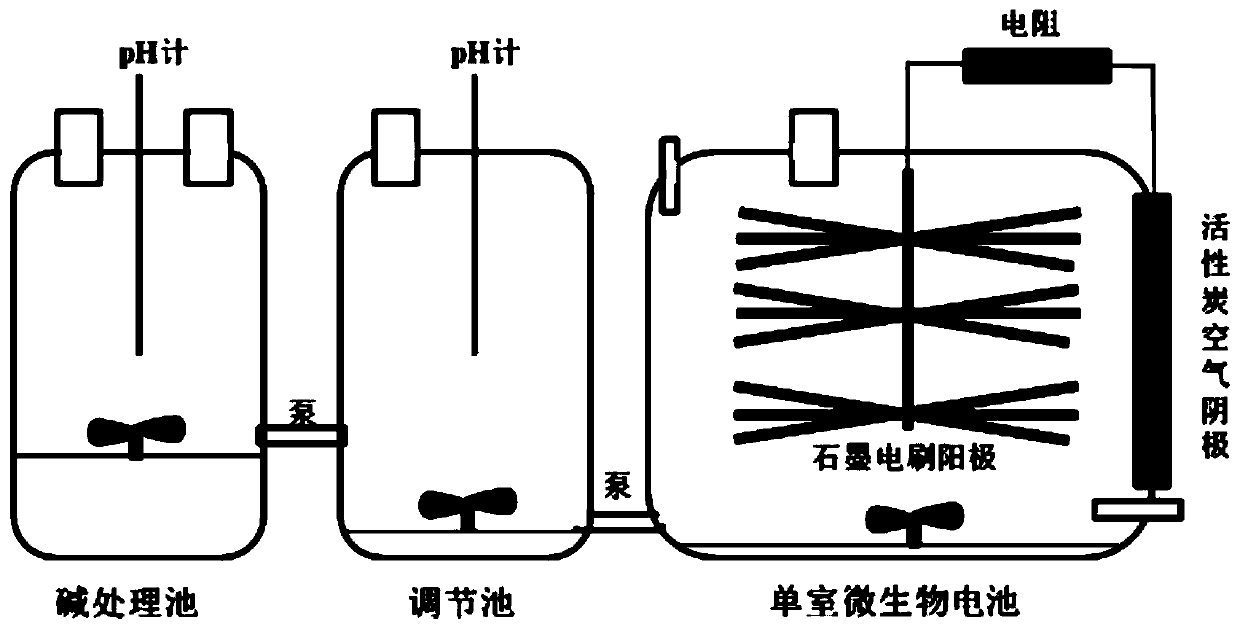

[0024] A sludge treatment method for alkaline treatment coupled with a single-chamber microbial electrochemical system, the specific steps are as follows:

[0025] (1) Alkali treatment of sludge: Collect samples of excess sludge from sewage treatment plants, import 1000 mg of excess sludge from the sludge inlet of the alkali treatment tank into the alkali treatment tank, measure the pH value with a pH meter, and determine the pH of the original excess sludge The value is about 6.5. While the agitator is stirring continuously, add NaOH (2mol / L) through the acid-base adjustment port of the alkali treatment tank to adjust the pH value of the remaining sludge to 12, and keep it at room temperature for 14 hours;

[0026] (2) Construction of a single-chamber microbial battery: Take 100 mg of raw sludge (containing mature strains) in the secondary sedimentation tank of a sewage treatment plant, inoculate it into a single-chamber microbial battery from the strain inoculation port, and ...

Embodiment 2

[0030] A sludge treatment method for alkaline treatment coupled with a single-chamber microbial electrochemical system, the specific steps are as follows:

[0031] (1) Alkali treatment of sludge: Collect samples of excess sludge from sewage treatment plants, import 1000 mg of excess sludge from the sludge inlet of the alkali treatment tank into the alkali treatment tank, measure the pH value with a pH meter, and determine the pH of the original excess sludge The value is about 6.5. While the agitator is constantly stirring, add NaOH (1.5mol / L) through the acid-base adjustment port of the alkali treatment tank to adjust the pH value of the remaining sludge to 10, and keep it at room temperature for 15 hours;

[0032](2) Construction of a single-chamber microbial battery: Take 90 mg of raw sludge (containing mature strains) in the secondary sedimentation tank of a sewage treatment plant, inoculate it into a single-chamber microbial battery from the strain inoculation port, and mi...

Embodiment 3

[0036] A sludge treatment method for alkaline treatment coupled with a single-chamber microbial electrochemical system, the specific steps are as follows:

[0037] (1) Alkali treatment of sludge: Collect samples of excess sludge from sewage treatment plants, import 1000 mg of excess sludge from the sludge inlet of the alkali treatment tank into the alkali treatment tank, measure the pH value with a pH meter, and determine the pH of the original excess sludge The value is about 6.5. While the agitator is stirring continuously, add NaOH (1mol / L) through the acid-base adjustment port of the alkali treatment pool to adjust the pH value of the remaining sludge to 7, and keep it at room temperature for 16 hours;

[0038] (2) Construction of a single-chamber microbial battery: Take 110 mg of raw sludge (containing mature strains) in the secondary sedimentation tank of a sewage treatment plant, inoculate it into a single-chamber microbial battery from the strain inoculation port, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com