Method for treating antimony-polluted river water

A water treatment and river channel technology, applied in water/sewage treatment, polluted waterways/lakes/ponds/rivers treatment, water/sludge/sewage treatment, etc., can solve cumbersome processing steps, short processing time, and high processing speed Slow and other problems, achieve high antimony removal efficiency, short processing time, and reduce the effect of processing limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

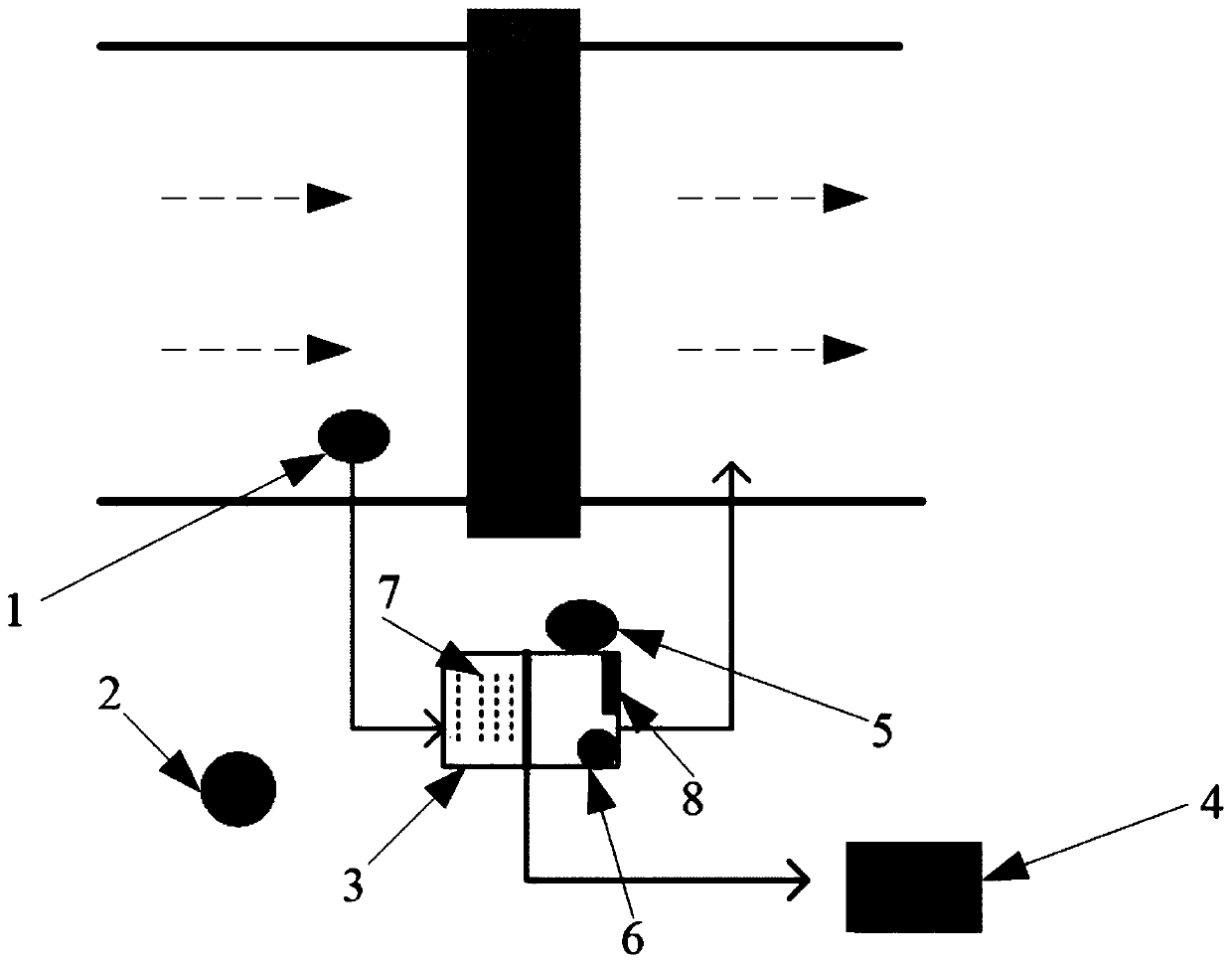

[0049] Set up a retaining dam at the boundary of the polluted river, and build a reactor 3 10m beside the polluted river. The overall size of the reactor 3 is 5m*5m*5m, and the effective volume is 112.5m 3 ,Such as figure 1 As shown, the reactor 3 includes an aeration device 7, an online detector 6 and a decanter 8, and the aeration device 7 is arranged at the bottom of the reactor 3 to promote the thorough mixing of the antimony removal agent and the water body; The on-line detector 6 is located at the end of the reactor 3 for on-line monitoring of the total antimony content, and the decanter 8 is used to filter the precipitate produced in the antimony removal process, and the produced precipitate is transported to the sludge drying Plant 4. The first lift pump 1 for introducing the polluted water body into the reactor 3 is arranged beside the river course, and the second lift pump 5 and the dosing pump 5 for pumping back the water body in the reactor 3 to the polluted area ...

Embodiment 2

[0056] Set up a retaining dam at the boundary of the polluted river, and build a reactor 3 at 10m beside the polluted river. The overall size of the reactor 3 is 5m*5m*5m, and the effective volume is 112.5m 3 , The structure of the reactor 3 is the same as in Example 1.

[0057] The polluted river water is introduced into the reactor 3 through the first lifting pump 1 and the water volume is controlled. At the same time, the dosing device 2 is turned on to transport the compound antimony removal agent. The compound antimony removal agent uses ferric chloride, sodium hydroxide, hydroxide It is prepared by mixing calcium and water. The mass ratio of ferric chloride, sodium hydroxide, calcium hydroxide and water in the compound antimony removal agent is 8:4:2:110, and the dosage keeps the mass ratio of iron and antimony at 5000:1, that is, 22kg compound agent / t polluted water body;

[0058] The aeration device 7 is turned on, under the action of aeration and stirring, the medica...

Embodiment 3

[0062] Set up a retaining dam at the boundary of the polluted river, and build a reactor 3 at 10m beside the polluted river. The overall size of the reactor 3 is 5m*5m*5m, and the effective volume is 112.5m 3 , The structure of the reactor 3 is the same as in Example 1.

[0063] The polluted river water is introduced into the reactor 3 through the first lifting pump 1 and the water volume is controlled. At the same time, the dosing device 2 is turned on to transport the compound antimony removal agent. The compound antimony removal agent uses ferric chloride, sodium hydroxide, hydroxide It is prepared by mixing calcium and water. The mass ratio of ferric chloride, sodium hydroxide, calcium hydroxide and water in the compound antimony removal agent is 8:4:2:120, and the dosage keeps the mass ratio of iron and antimony at 6000:1, that is, 29kg compound medicine / t polluted water body;

[0064] The aeration device 7 is turned on, under the action of aeration and stirring, the med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com