Limiting protection structure for motor hoisting and transportation

A protective structure and motor technology, applied in transportation and packaging, packaging food, assembling machines, etc., can solve problems such as inability to buffer the motor, damage to the internal parts of the motor, and affect the service life of the motor, so as to ensure the protection effect and improve the limit The effect of bit fixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

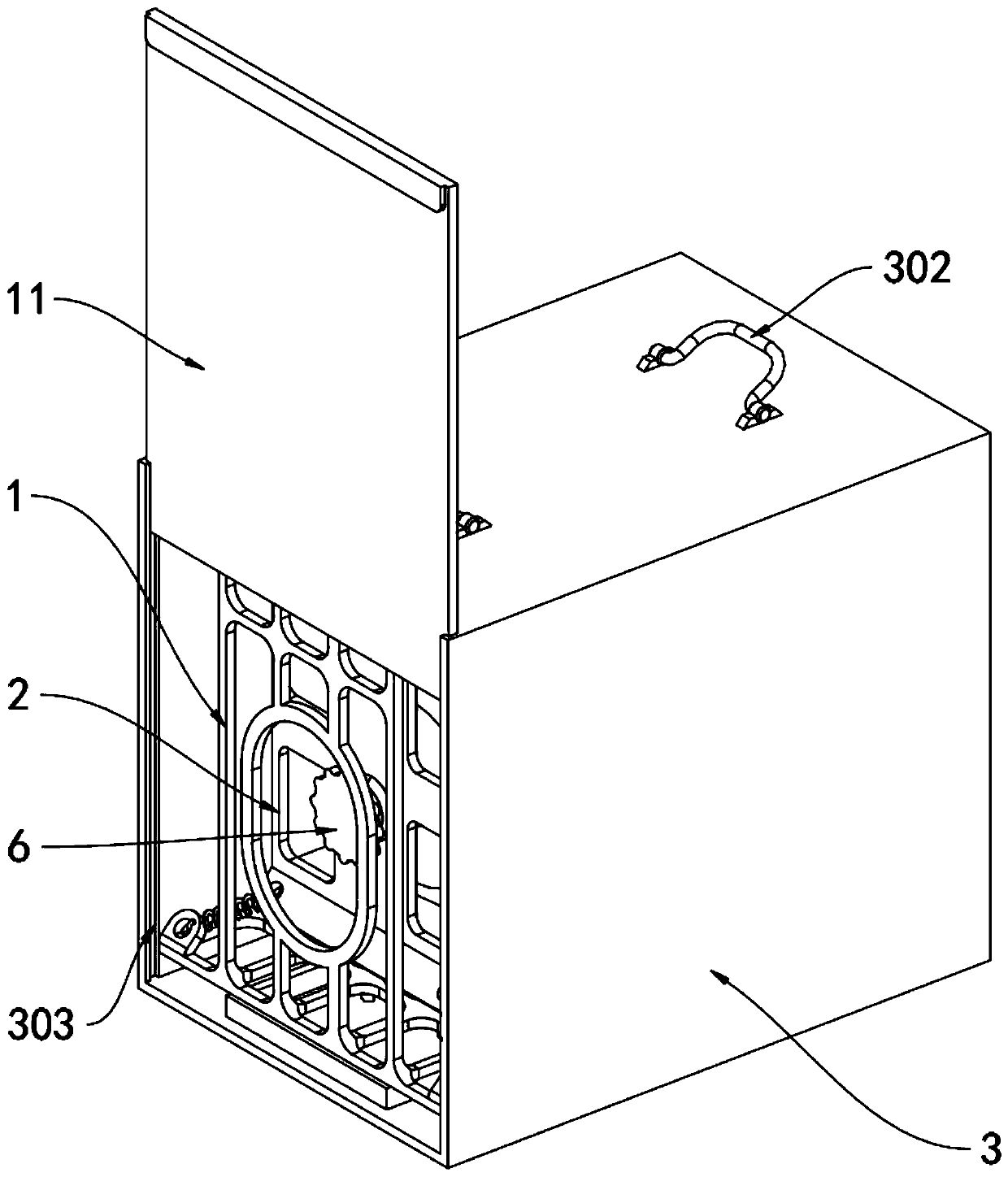

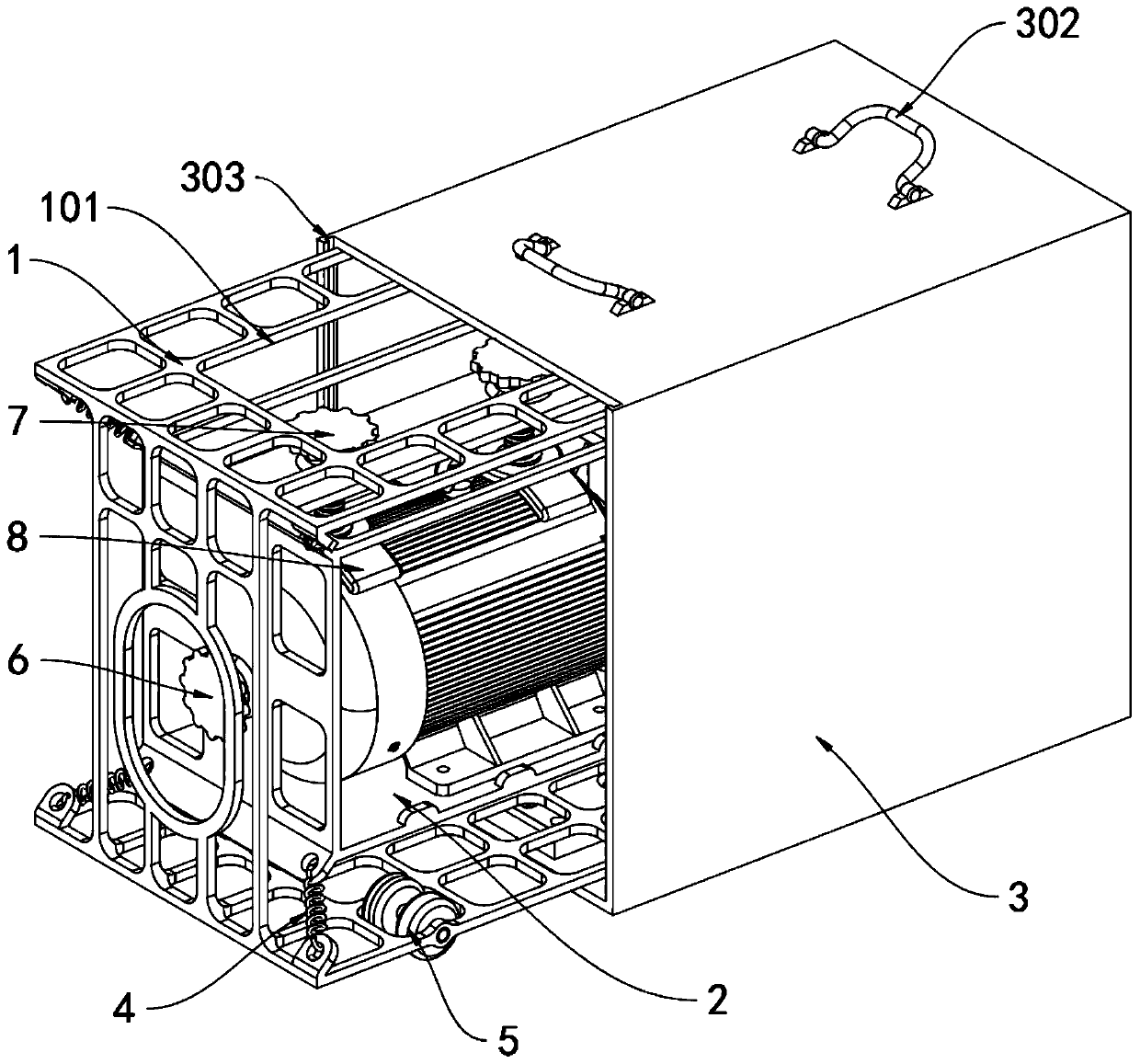

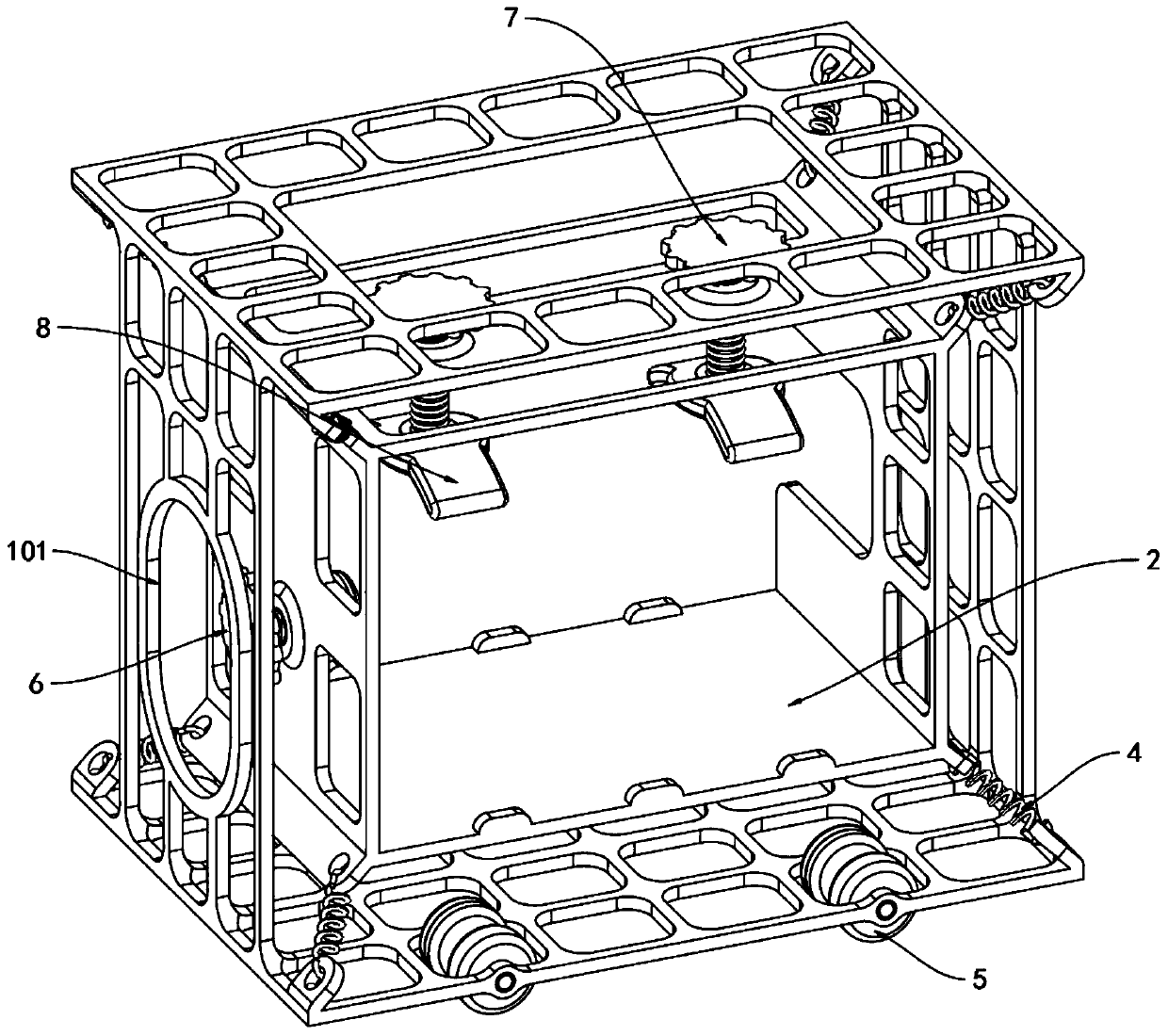

[0030] as attached figure 1 to attach Figure 9 Shown:

[0031] The invention provides a position-limiting protective structure for hoisting and transporting a motor, which includes an outer protective frame 1, an inner protective frame 2, an outer protective shell 3, a position-limiting bolt 6, a pressing bolt 7, an arc-shaped position-limiting plate 8, a porous moisture-absorbing Plate 9 and outer baffle plate 11; outer cage 1 is a square structure, and the top four ends and bottom four ends of the outer cage 1 are respectively connected with the buffer spring 4; the inner cage 2 is a square structure, and the inner cage 2 is The suspended shape is located inside the outer casing 1; the top of the outer casing 3 is provided with two hoisting handles 302, and the outer casing 1 and the inner casing 2 are both located inside the outer casing 3; there are eight buffer springs 4, divided into There are two sets of upper and lower groups, and the inner cage 2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com