Single-box multi-layer steel bar classification storage method

A steel, single-box technology, applied in loading/unloading, packaging, internal accessories, etc., can solve the problems of occupying space, lack of worker awareness, unused steel bars, etc., to reduce labor intensity, improve economic benefits, reduce possible effects of congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

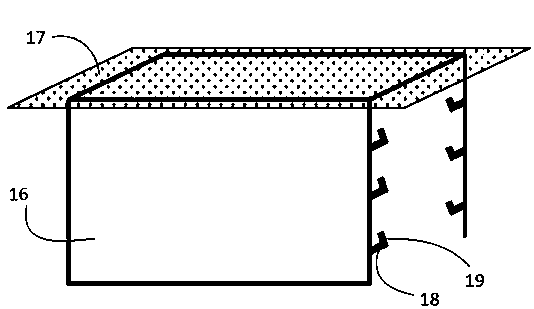

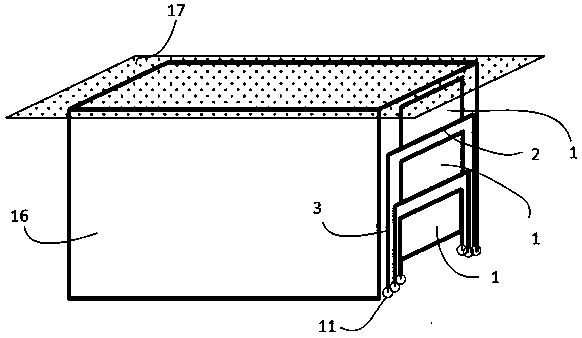

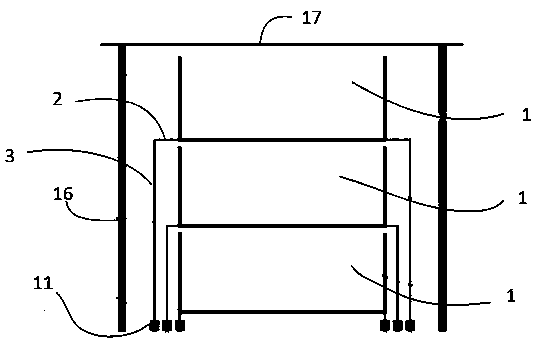

[0038] Example: such as Figure 1 to Figure 8 As shown, the present invention provides a kind of single case multi-layer steel bar classification storage method, comprises the following steps:

[0039] A. Harden the site where the steel bars are stacked, and set up a drainage system around the site;

[0040] B. process and manufacture to form a single box multi-layer steel bar classification storage structure, the single box multi-layer steel bar classification storage structure includes a box body 16, a plurality of steel bar storage tanks 1, a rainproof shed 17 and a sliding load-bearing structure, the box body 16 includes two side plates and an end plate connected to one end of the two side plates, so that the box body 16 forms a structure with an open upper side and the other end; Support structure 18, wherein, the heights of the two support structures 18 at the corresponding positions on the two side plates are consistent; the length direction of the support structure 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com