Independent suspension integrated wheel-side motor assembly

A technology of independent suspension and integrated wheel, applied in motion deposition, power unit, transportation and packaging, etc., can solve the problems of great influence on motor service life, large impact, increase the complexity and cost of suspension structure, and reduce Effects of unsprung mass, system simplification, and improved ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

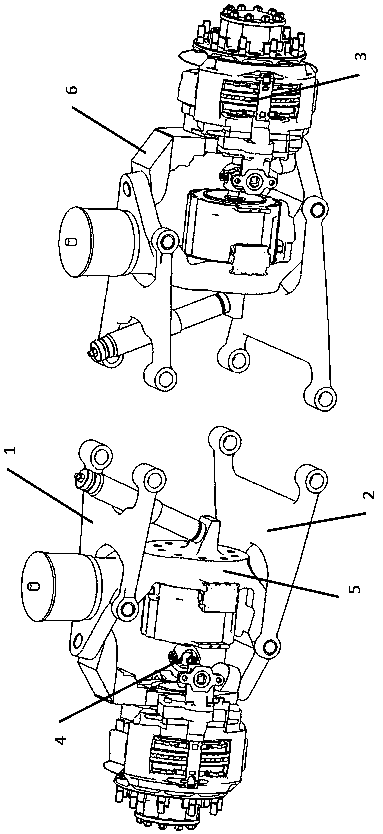

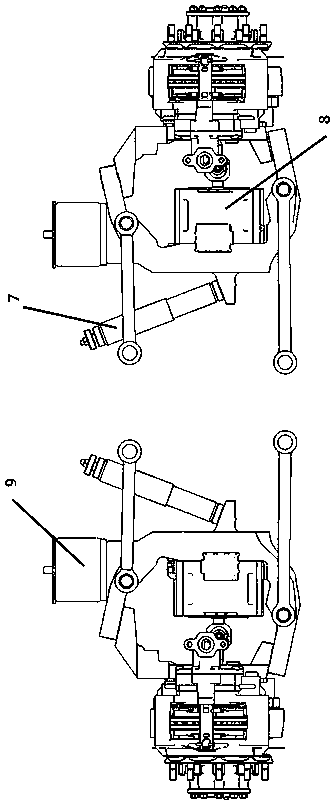

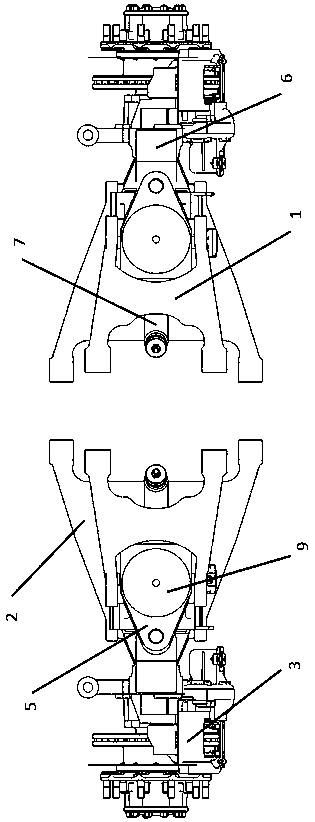

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, the present invention mainly consists of upper A arm 1, lower A arm 2, wheel end 3, cardan shaft 4, column 5, steering knuckle 6, shock absorber 7, motor 8, air spring 9, kingpin 12, stop Push bearing 13, speed reducer 14 etc. are formed. The suspensions on the left and right sides are connected with the vehicle frame separately, so that the independence when the left and right wheel ends 3 jump up and down can be realized. One end of the upper A-arm 1 and the lower A-arm 2 are respectively connected with the column 5 in a rotating pair, and the rotation axes of both are parallel to the ground. . The upper and lower ends of the column 5 are respectively connected with the upper and lower ends of the steering knuckle 6 in a rotating pair, and the axes of the upper and lower rotating pairs are coincident. Different from the traditional monolithic kingpin structure, more space can be provided for the arrangem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com