An ultra-high pressure pre-mixed abrasive jet abrasive amount adjustment feeding device

A technology of pre-mixing abrasive and feeding device, applied in abrasive feeding device, abrasive, metal processing equipment and other directions, can solve the problems of low cutting capacity, reducing the transmission efficiency of water medium to abrasive, and regulating the amount of abrasive, and achieves improved mixing. effect, improve the effective utilization rate, and reduce the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

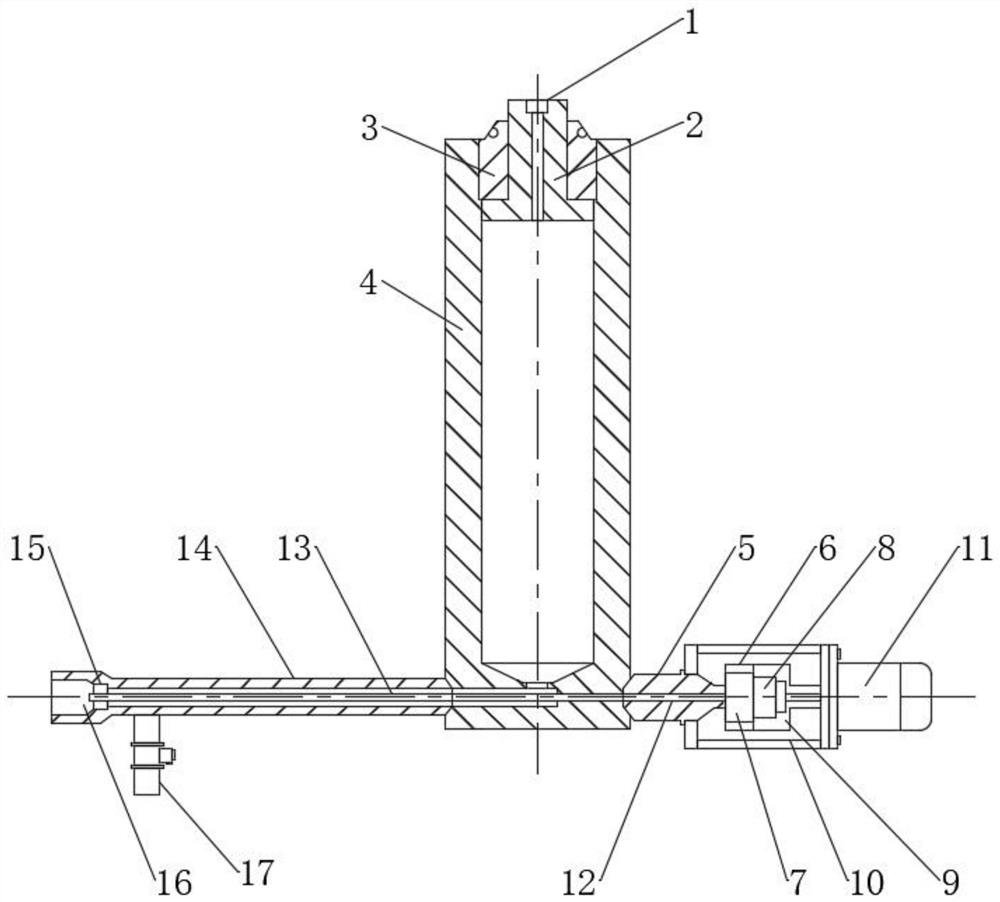

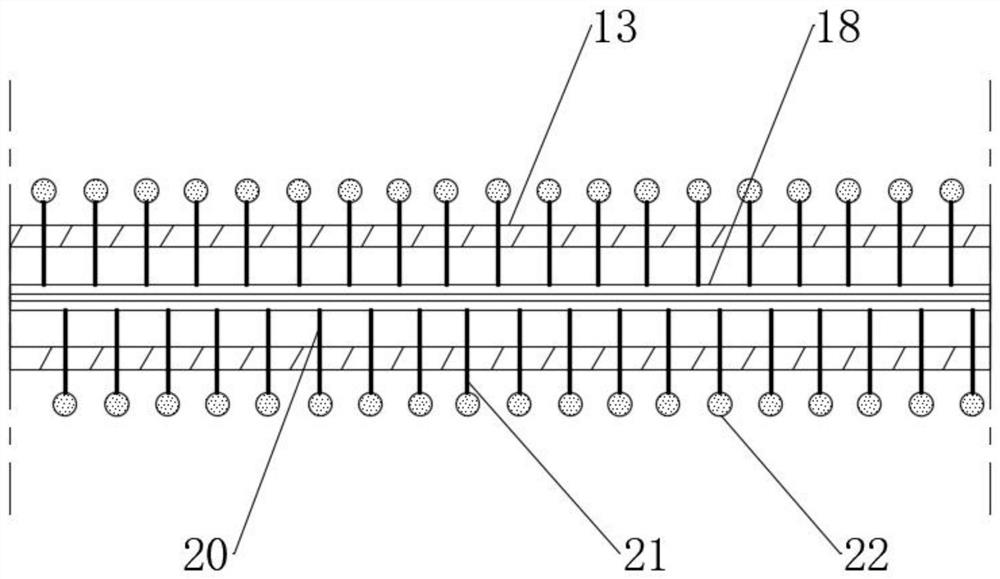

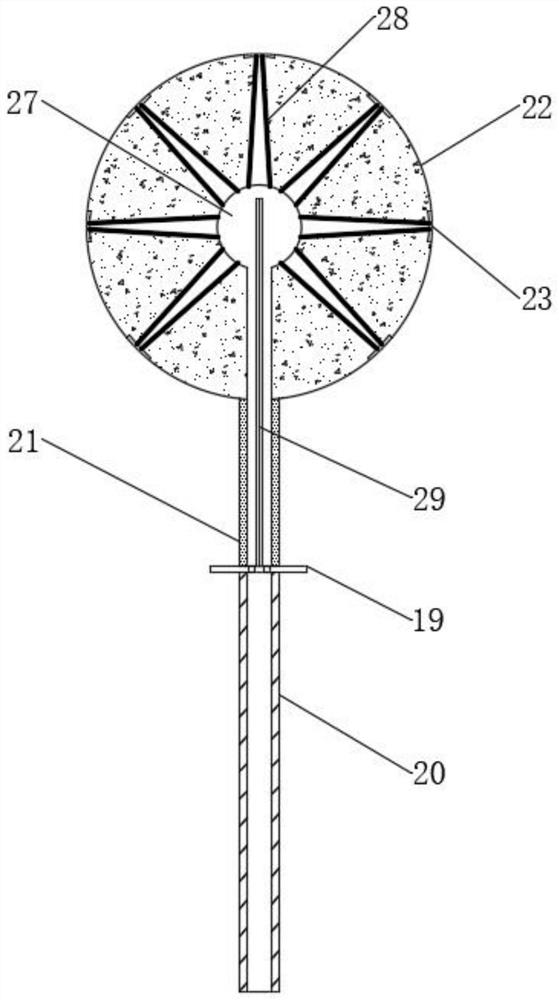

[0048] see figure 1 , an ultra-high pressure pre-mixed abrasive jet abrasive feed device for adjusting the amount of abrasive, comprising an abrasive barrel 4, an abrasive pot plug 2 is installed on the upper end of the abrasive barrel 4, a matching pressure cap 3 is installed on the upper end of the abrasive pot plug 2, and the abrasive pot plug A vertically distributed abrasive feeding port 1 is excavated on the head 2, a connecting block 5 is installed on the right side of the lower end of the abrasive cylinder 4, a motor seat 10 is fixedly installed on the outer end of the connecting block 5, and a speed regulating motor 11 is fixedly installed on the right end of the motor seat 10. The output end of the speed-regulating motor 11 is fixedly connected with an outer magnetic steel base 9 located in the motor base 10, an outer magnetic steel base 6 is installed on the outer magnetic steel base 9, and the inner rotation of the outer magnetic steel 6 is connected with a matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com