A method for deep removal of soluble components of industrial waste slag

An industrial waste residue removal technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of insufficient dissolution and complete separation, to ensure hydrolysis or dissolution, improve removal efficiency, and energy efficiency. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

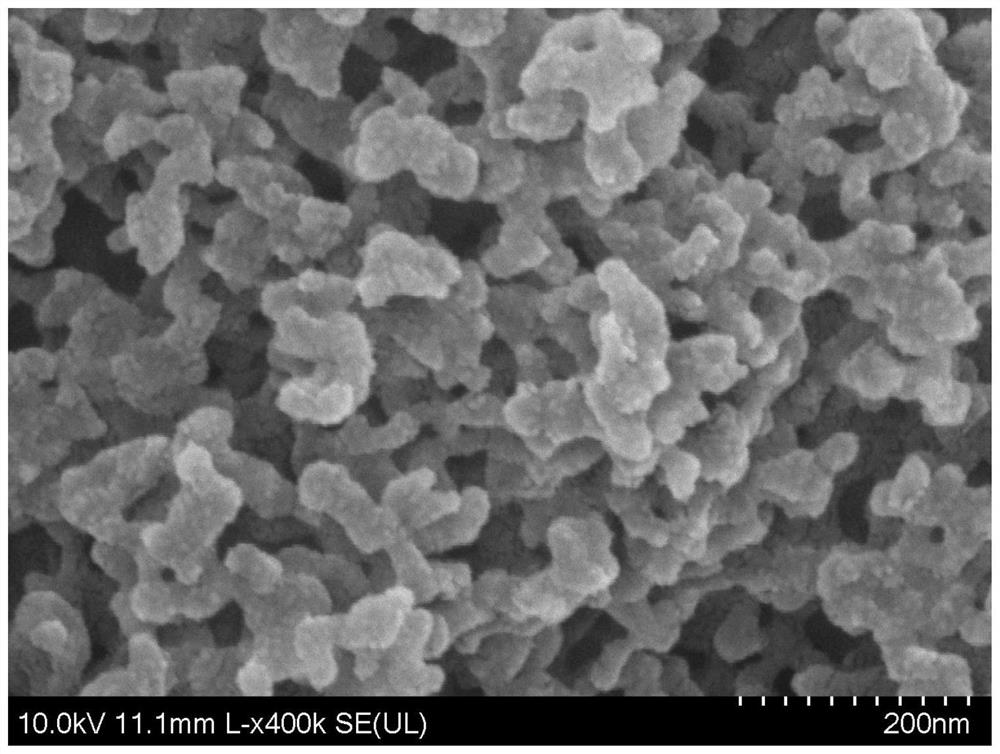

Image

Examples

Embodiment 1

[0025] This embodiment relates to a deep removal treatment method for soluble components of domestic waste incineration fly ash, which is specifically divided into the following steps:

[0026] Step 1. Add 50 kg of sodium silicate to water, stir at 20°C for 10 minutes at high speed, the speed of high speed stirring is 300r / min, and control the pH value of the solution to 10;

[0027] Step 2, add 150 kilograms of domestic waste incineration fly ash and 450 kilograms of water to the solution in step 1, and mix to form a suspension;

[0028] Step 3: Add 3 kg of aluminum powder to the suspension, and stir at 80°C for 30 minutes at a low speed of 50 r / min;

[0029] Step 4: Filter and dry the suspension in Step 3 to obtain domestic waste incineration fly ash after removal of soluble components.

Embodiment 2

[0031] This embodiment relates to a deep removal treatment method for soluble components of aluminum ash, which is specifically divided into the following steps:

[0032] Step 1. Add 30 kg of silicon dioxide to water, stir at 40°C for 30 minutes at high speed, the speed of high speed stirring is 400r / min, and control the pH value of the solution to 11;

[0033] Step 2, add 150 kilograms of aluminum ash and 750 kilograms of water to the solution of step 1, and mix to form a suspension;

[0034] Step 3: Add 1.25 kg of hydrogen peroxide into the suspension, and stir at 70°C for 65 minutes at a low speed of 150 r / min;

[0035] Step 4: Filter the suspension in Step 3 and dry to obtain aluminum ash after removing soluble components.

Embodiment 3

[0037] This embodiment relates to a deep removal treatment method for soluble components of salt-containing waste residue, which is specifically divided into the following steps:

[0038] Step 1. Add 30 kg of methyl silicate to water, stir at 30°C for 20 minutes at high speed, the speed of high speed stirring is 350r / min, and control the pH value of the solution to 12;

[0039] Step 2, add 140 kilograms of saline waste residue and 560 kilograms of water to the solution of step 1, and mix to form a suspension;

[0040] Step 3: Add 1.25 kg of hydrogen peroxide into the suspension, and stir at 60°C for 60 minutes at a low speed of 100 r / min;

[0041] Step 4: Filter and dry the suspension in Step 3 to obtain salt-containing waste residue after removal of soluble components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com