Food sauce and preparation method thereof

A food and sauce technology, applied in the field of food sauce and its preparation, can solve the problems of the taste and fluidity of food sauce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also relates to a preparation method of food sauce, comprising:

[0052] (1) Stir sesame and / or peanut butter with lauric acid type oil;

[0053] (2) Mix the aqueous solution of inulin and the mixture obtained in step (1).

[0054] The sesame and / or peanuts can be ground into sauce by conventional methods in the art. Before grinding the sauce, conventional methods can be used to remove impurities, wash, peel, and roast sesame seeds or peanuts. For example, for sesame seeds, the sesame seeds can be sieved to remove impurities, washed with clean water, drained, and processed with a peeling machine. Peeling, then properly roasting the peeled sesame seeds at 150°C-200°C, and then grinding the roasted sesame seeds into paste with a refiner, the particle size can be controlled at less than 5 microns; for peanuts, peanuts can be processed After sifting and removing impurities, wash with clean water, dry with hot air, and then properly roast the dried pe...

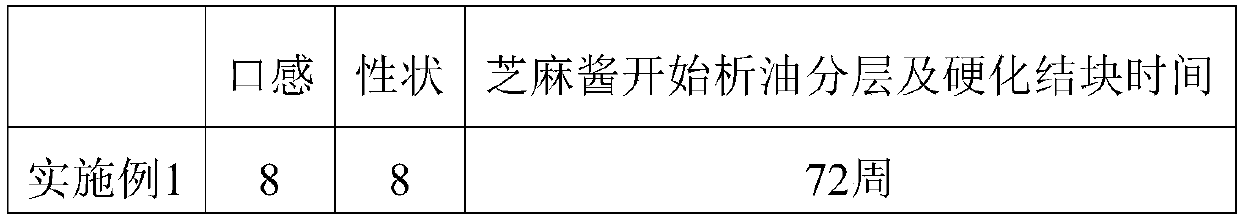

Embodiment 1

[0093] After sieving the black sesame seeds to remove impurities, wash them twice with clean water, drain them, and peel them with a peeling machine, then put the peeled sesame seeds in a frying pan with a temperature of 170°C-190°C and roast for 10min-30min. The pulp machine grinds the roasted sesame seeds into paste, and the particle size is controlled to be less than 3 microns.

[0094] Take by weighing the sesame paste of 75g, the palm kernel oil of 15g (according to fat fatty acid total weight, lauric acid content is 45%) and the compound vitamin (V D and V KThe weight ratio is 10:1) under the condition of 80 ℃ mechanical stirring 0.5h, the stirring rate is 500rpm, then add 25mL 20% (w / v) inulin (inulin source is chicory) aqueous solution, and add 3g salt, Stir and mix at 40°C for 10min (stirring speed is 500rpm), perform high-pressure homogenization treatment with a homogenization pressure of 10MPa, and finally sterilize at 95°C for 30min to obtain a sesame paste produc...

Embodiment 2

[0113] After the white sesame is sieved to remove impurities, wash it twice with clean water, drain it, and peel it with a peeling machine, then put the peeled sesame in a frying pan with a temperature of 170°C-190°C and roast for 10min-30min, grind it with a grinder The pulp machine grinds the roasted sesame seeds into paste, and the particle size is controlled to be less than 3 microns.

[0114] Take by weighing the tahini of 85g, the coconut oil of 5g (in terms of total weight of fatty acids, lauric acid content is 56%) and the compound vitamin (V D and V K The weight ratio is 100:1) mechanically stirred at 30°C for 1.5h at a stirring rate of 300rpm, then added 20mL of 30% (w / v) inulin (the raw material source of inulin is Jerusalem artichoke) aqueous solution, and added 1g Salt was stirred and mixed at 60°C for 30min (stirring speed was 300rpm), subjected to high-pressure homogenization treatment at a homogenization pressure of 30Mpa, and finally sterilized at 95°C for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com