Instant rice retrogradation inhibitor, instant rice, and preparation method and application of instant rice retrogradation inhibitor and instant rice

A technology of instant rice and inhibitor, which is applied in the direction of food science, etc., can solve the problems that instant rice has no obvious anti-regeneration effect and affects the sensory quality of instant rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] First aspect, the present invention provides a kind of preparation method of instant rice retrogradation inhibitor, and the method comprises the steps:

[0036] 1) Mix corn-derived starch with a pH of 9-11.5 and Na 2 SO 4 The mixed solution and propylene oxide are subjected to the first contact reaction, and the first contact reaction product is subjected to the first solid-liquid separation to obtain the corn-derived starch after the first contact reaction;

[0037] 2) After preparing a starch emulsion with a pH value of 5-8 by using a hydrochloric acid aqueous solution with a concentration of 3-8% by weight and the corn-derived starch after the first contact reaction, mix with CuSO 4 and H 2 o 2 carry out the second contact reaction;

[0038] 3) The second contact reaction product obtained in step 2) is subjected to a second solid-liquid separation.

[0039] According to the preparation method of the present invention, preferably, the pH value of the mixed soluti...

Embodiment 1-7

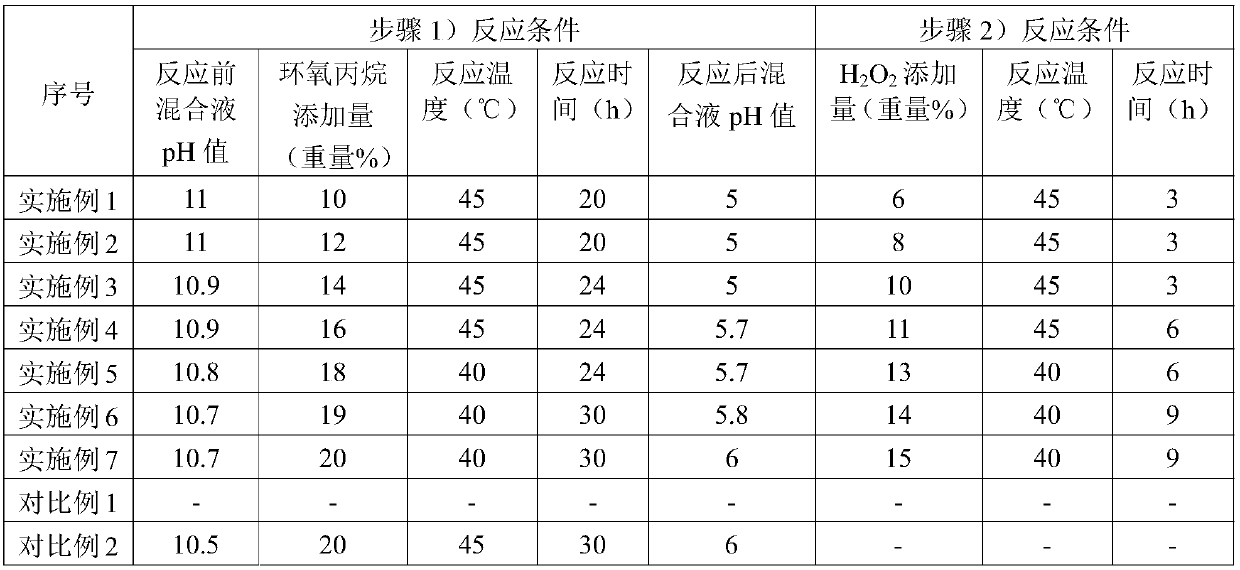

[0073] Embodiment 1-7 prepares retrogradation inhibitor of instant rice

[0074] 1) With raw rice starch (RS, specifically japonica rice starch) as raw material, rice starch milk with a concentration of 42% by weight is prepared; Na 2 SO 4 , and then adjust the pH to 10.5-11 with NaOH; under nitrogen protection, add 10-20% by weight of propylene oxide (based on the weight of rice starch), and react at 40-45°C for 20-30h; then use 5 Adjust the pH value to 5-6 with the weight percent HCl aqueous solution, centrifuge and wash, dry at 55° C. for 10 hours, and then pulverize and pass through a 100-mesh sieve.

[0075] 2) Adjust the pH value of the starch emulsion to 7.5 with 5% by weight of HCl aqueous solution of the dried starch, and add 10 mL of CuSO with a concentration of 0.5% by weight 4 Solution (based on the weight of rice starch, CuSO 4 The consumption is 10% by weight), then adding concentration is 30% by weight of H 2 o 2 (Based on the weight of rice starch, H 2 o ...

Embodiment 8

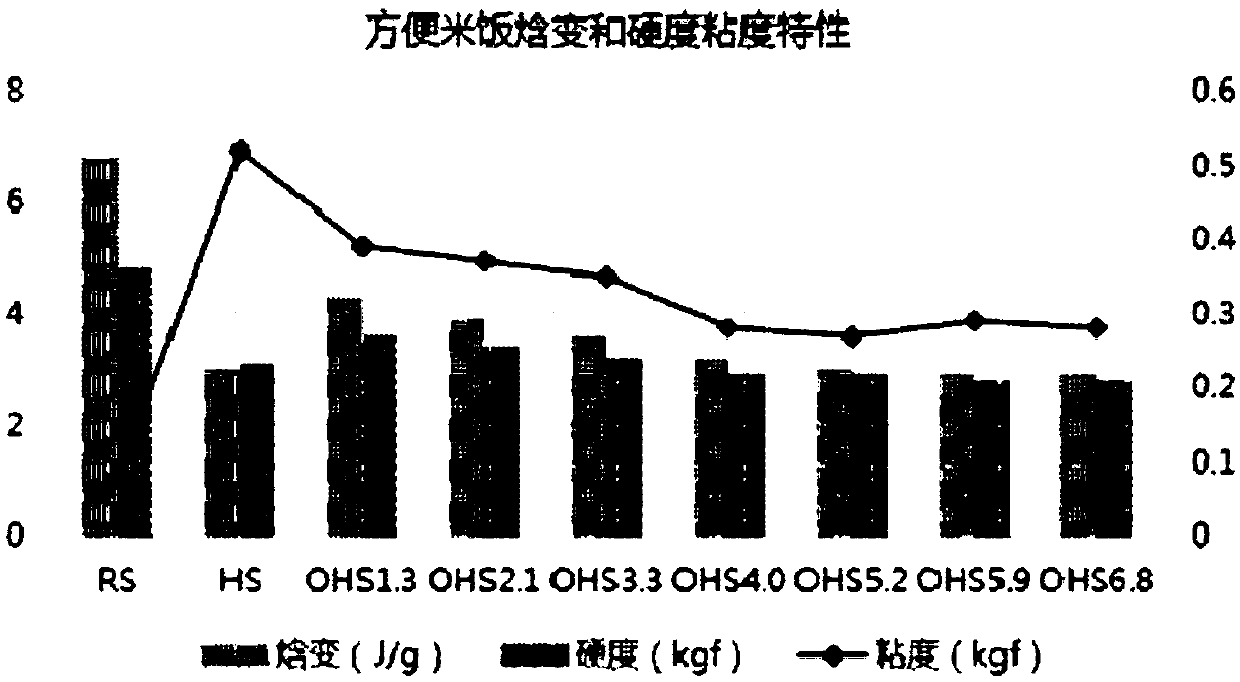

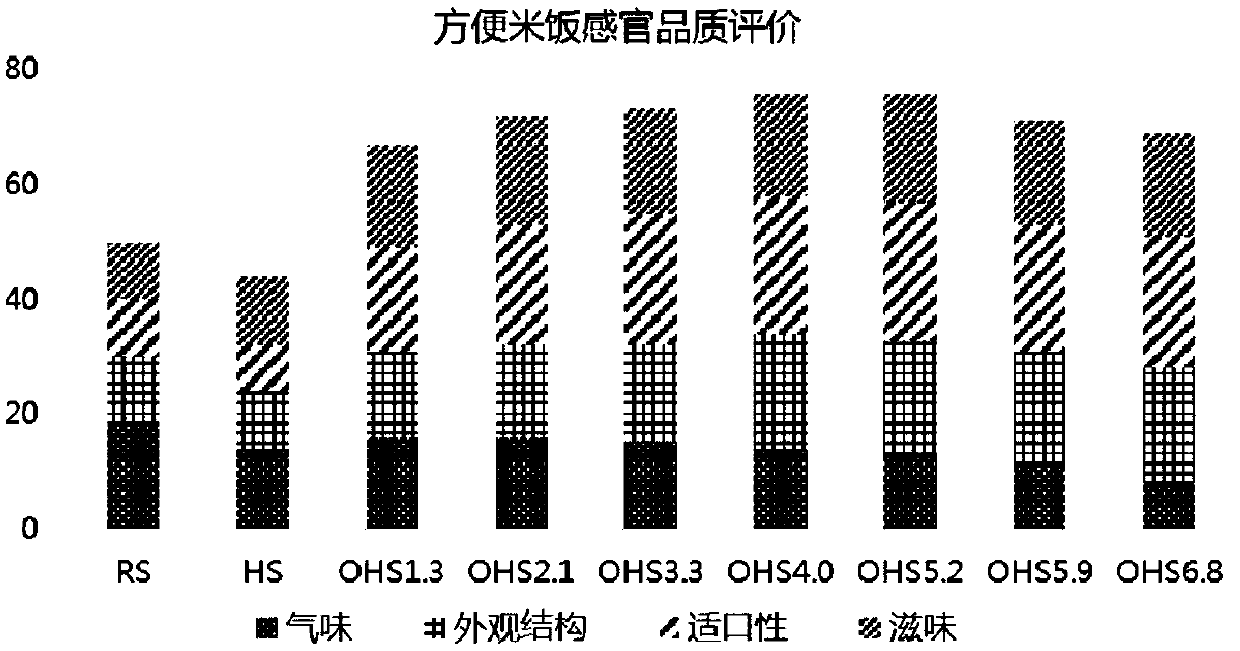

[0086] Embodiment 8 prepares instant rice

[0087] Rinse the rice, add water with a weight ratio of rice to water of 1:1.3, soak for 20min, take the total weight of the rice as a basis, and prepare 5% by weight of Example 1-7 and Comparative Example 1-2 The instant rice retrogradation inhibitor (the instant rice retrogradation inhibitor is configured as an emulsion with a mass fraction of 10%, and is added to the rice after the emulsion is completely gelatinized) is fully mixed. After cooking the rice for 30 minutes, add it quantitatively into the cooking bag, and sterilize it at 121°C for 20 minutes. The prepared instant rice is counted as instant rice OHS1.3, instant rice OHS2.1, instant rice OHS3.3, instant rice OHS4.0 , instant rice OHS5.2, instant rice OHS5.9, instant rice OHS6.8, instant rice RS and instant rice HS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak viscosity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com