Preparation method and application of ZnFe2O4 modified electrode material

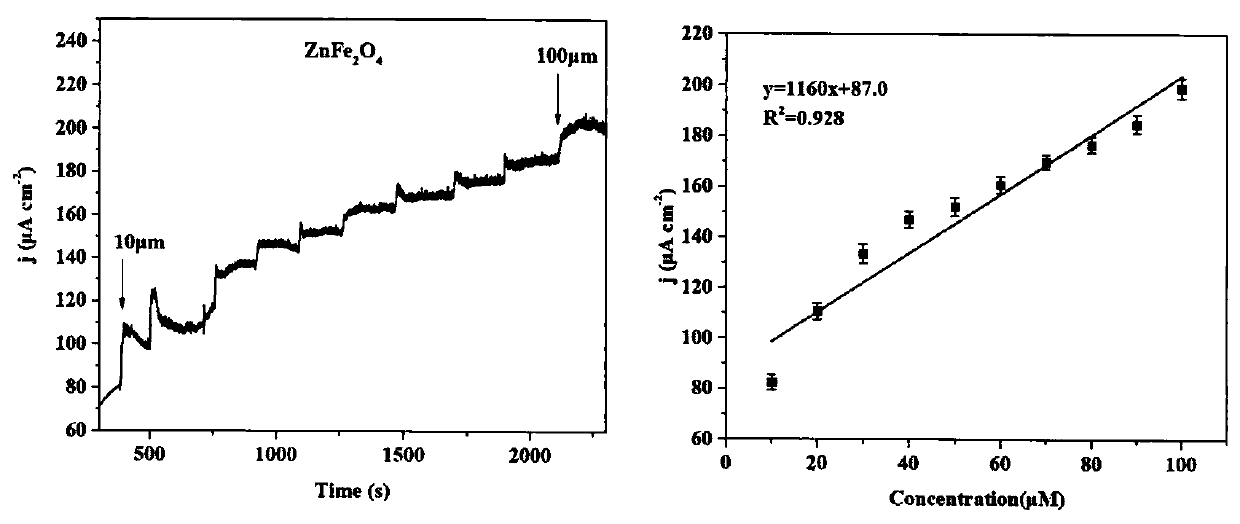

A technology for modifying electrodes and znfe2o4, which can be used in electrochemical sensors and non-enzymatic glucose detection fields, and can solve problems such as insufficient long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

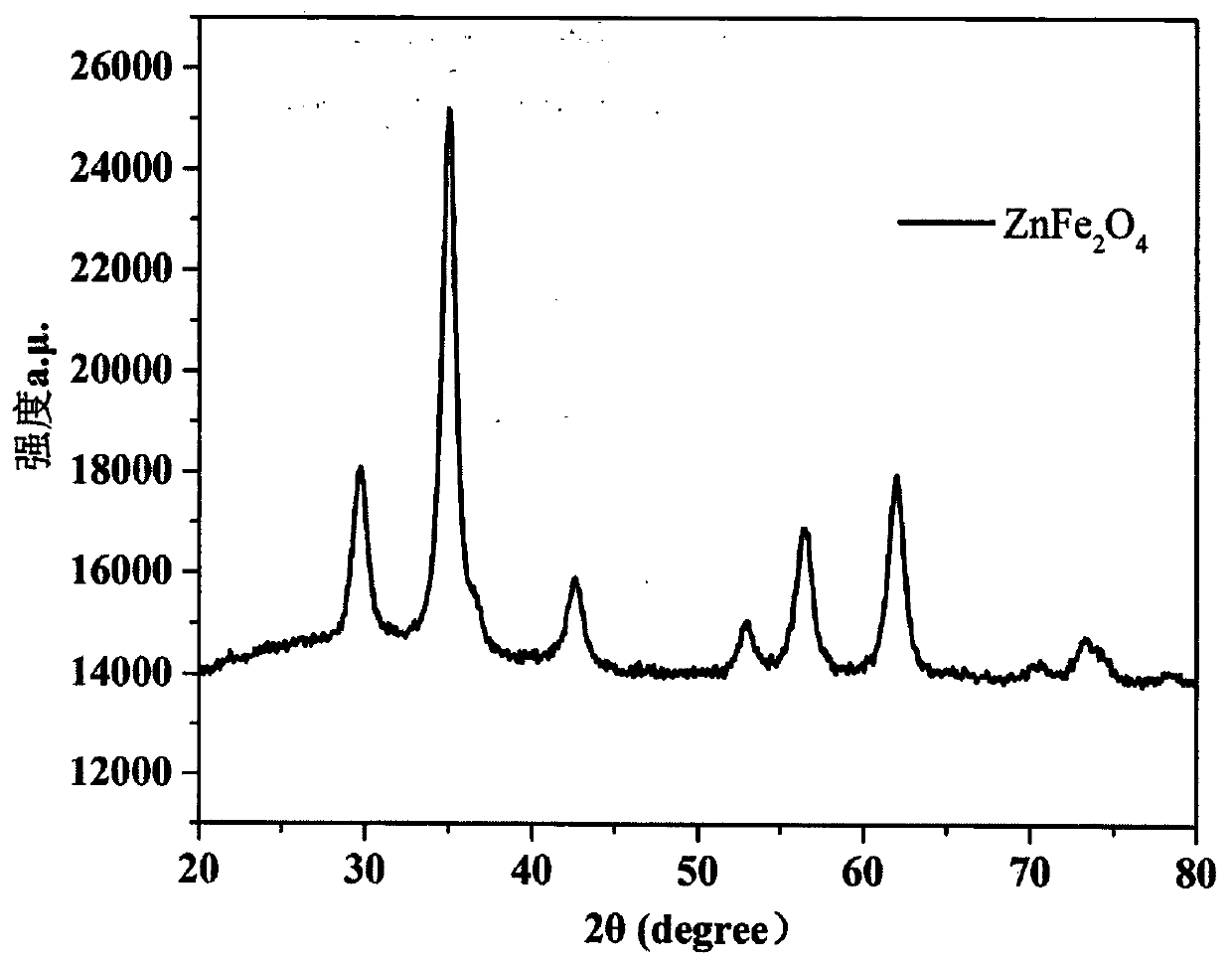

[0022] ZnFe 2 o 4 Preparation of nanoparticles:

[0023] a, Fe:Zn=2:1 is weighed ferric nitrate and zinc acetate by atomic molar ratio, is dissolved in deionized water, stirs evenly, is mixed with concentration and is 0.1mol / L metal salt mixed solution;

[0024] B, again press sodium hydroxide and metal ion molar ratio 1.4:1, be mixed with concentration and be 1mol / L sodium hydroxide solution;

[0025] c. Add the metal salt mixed solution obtained in step a dropwise to the sodium hydroxide solution obtained in step b, stir magnetically for 5 hours at room temperature to obtain the mixture, age for 12 hours, and then centrifuge the aged mixed solution to obtain ZnFe 2 o 4 Hydroxide mixed precipitation;

[0026] D, get the ZnFe that step c obtains 2 o 4 The mass of hydroxide mixed precipitate is 2.0g, dispersed in the mixed solution of deionized water and ethanol containing polyvinylpyrrolidone, and placed in a 100ml polytetrafluoroethylene liner, the hydrothermal temperat...

Embodiment 2

[0034] ZnFe 2 o 4 Preparation of nanoparticles:

[0035] a, Fe:Zn=2:1 is weighed ferric nitrate and zinc acetate by atomic molar ratio, is dissolved in deionized water, stirs evenly, is mixed with concentration and is 0.1mol / L metal salt mixed solution;

[0036] B, then by sodium hydroxide and metal ion molar ratio 1.2:1, be prepared into concentration and be 0.1mol / L sodium hydroxide solution;

[0037] c. Add the metal salt mixed solution obtained in step a dropwise to the sodium hydroxide solution obtained in step b, stir magnetically at room temperature for 4 h to obtain the mixture, age for 24 h, and then centrifuge the aged mixed solution to obtain ZnFe 2 o 4 Hydroxide mixed precipitation;

[0038] D, get the ZnFe that step c obtains 2 o 4 The mass of hydroxide mixed precipitate is 1.0g, dispersed in the mixed solution of deionized water and ethanol containing polyvinylpyrrolidone, and placed in a 100ml polytetrafluoroethylene liner, the hydrothermal temperature is ...

Embodiment 3

[0047] ZnFe 2 o 4 Preparation of nanoparticles:

[0048] a, Fe:Zn=2:1 is weighed ferric nitrate and zinc acetate by atomic molar ratio, is dissolved in deionized water, stirs evenly, is mixed with concentration and is 1.5mol / L metal salt mixed solution;

[0049] B, again press sodium hydroxide and metal ion molar ratio 1.6:1, be mixed with concentration and be 1.5mol / L sodium hydroxide solution;

[0050] c. Add the metal salt mixed solution obtained in step a dropwise to the sodium hydroxide solution obtained in step b, stir magnetically for 6 hours at room temperature to obtain the mixture, age for 16 hours, and then centrifuge the aged mixed solution to obtain ZnFe 2 o 4 Hydroxide mixed precipitation;

[0051] D, get the ZnFe that step c obtains 2 o 4 The mass of hydroxide mixed precipitate is 3.0g, dispersed in the mixed solution of deionized water and ethanol containing polyvinylpyrrolidone, and placed in a 100ml polytetrafluoroethylene liner, the hydrothermal temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com