A spherical industrial product grinding device for industrial product design

A technology for industrial products and industrial products, applied in the direction of grinding drive devices, spherical grinders, metal processing equipment, etc., can solve the problems of low grinding efficiency of spherical industrial products, increase the distance adjustment range, reduce labor intensity, and improve the grinding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

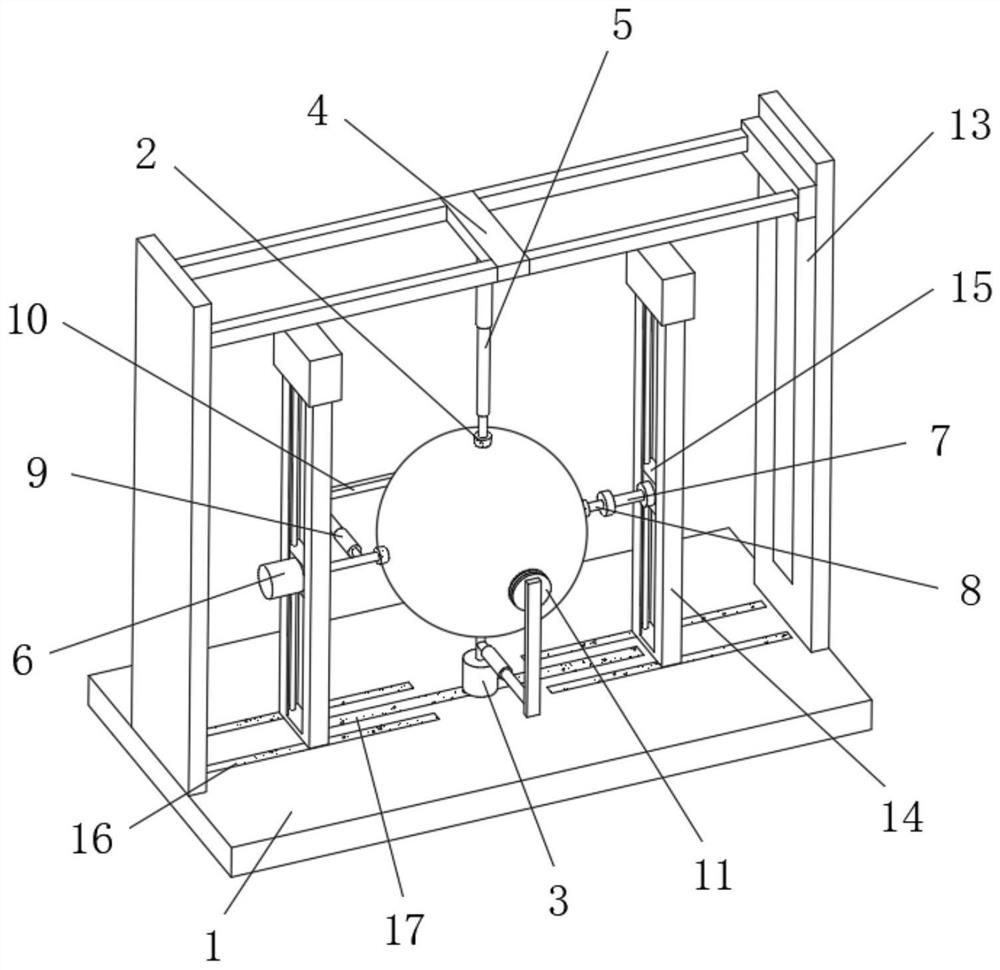

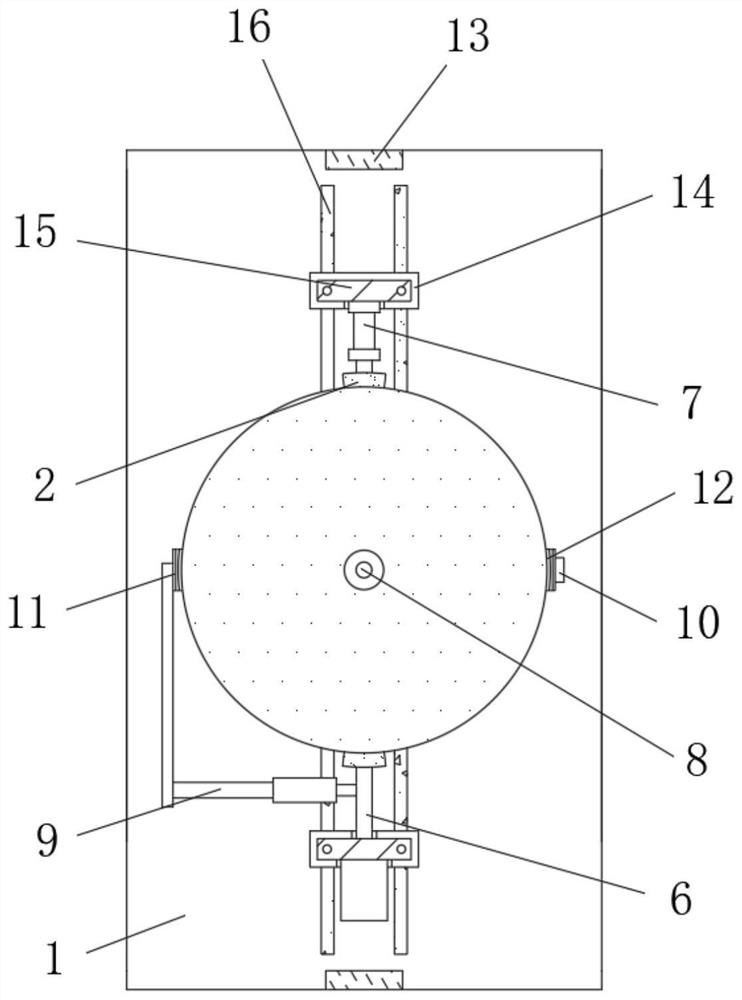

[0026] refer to Figure 1-3 , a spherical industrial product grinding device for industrial product design, including a base 1, a clamping mechanism and a grinding mechanism are arranged above the base 1, and the clamping mechanism is provided with four counter blocks 2 distributed in a circular array on the vertical surface, and One side of the block is arranged in an arc-shaped structure, the middle position of the top of the base 1 is fixed with a fixed box 3, and the inner wall of the fixed box 3 is fixed with a first motor, the output shaft of the first motor is fixed with a block 2, and the top of the base 1 A top plate 4 is arranged above the first motor, and a hydraulic telescopic rod 5 is fixed in the middle of the outer wall of the bottom of the top plate 4. The bottom end of the hydraulic telescopic rod 5 is fixed with a block 2, and both sides of the top of the base 1 are fixed with fixing seats. 14, and the opposite sides of the two fixed seats 14 are respectively...

Embodiment 2

[0032] refer to Figure 1-4 , a spherical industrial product grinding device for industrial product design, the connecting piece 10 is set as two auxiliary plates 19, and the two auxiliary plates 19 are respectively fixedly connected with the electric push rod 9 and the fixed plate 11, and between the two auxiliary plates 19 Fixedly connected with electric telescopic rod 20.

[0033] When in use, utilize the electric push rod 9 and the electric telescopic rod 20 to adjust the position of the grinding sandpaper 12, and the arc surface of the irregular ball-like industrial product surface wall can be polished, thereby further enhancing the actual use effect of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com