Method and device for improving wrinkles of dry diaphragm of lithium ion soft package laminated battery

A diaphragm wrinkle and lithium ion technology, applied in the field of lithium ion batteries, can solve problems such as uneven stress release improvement effect, adverse effects on the electrical performance of cells, and increase the manufacturing cost of the separator, so as to improve the wrinkle of the PP diaphragm, and the equipment investment is not high. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

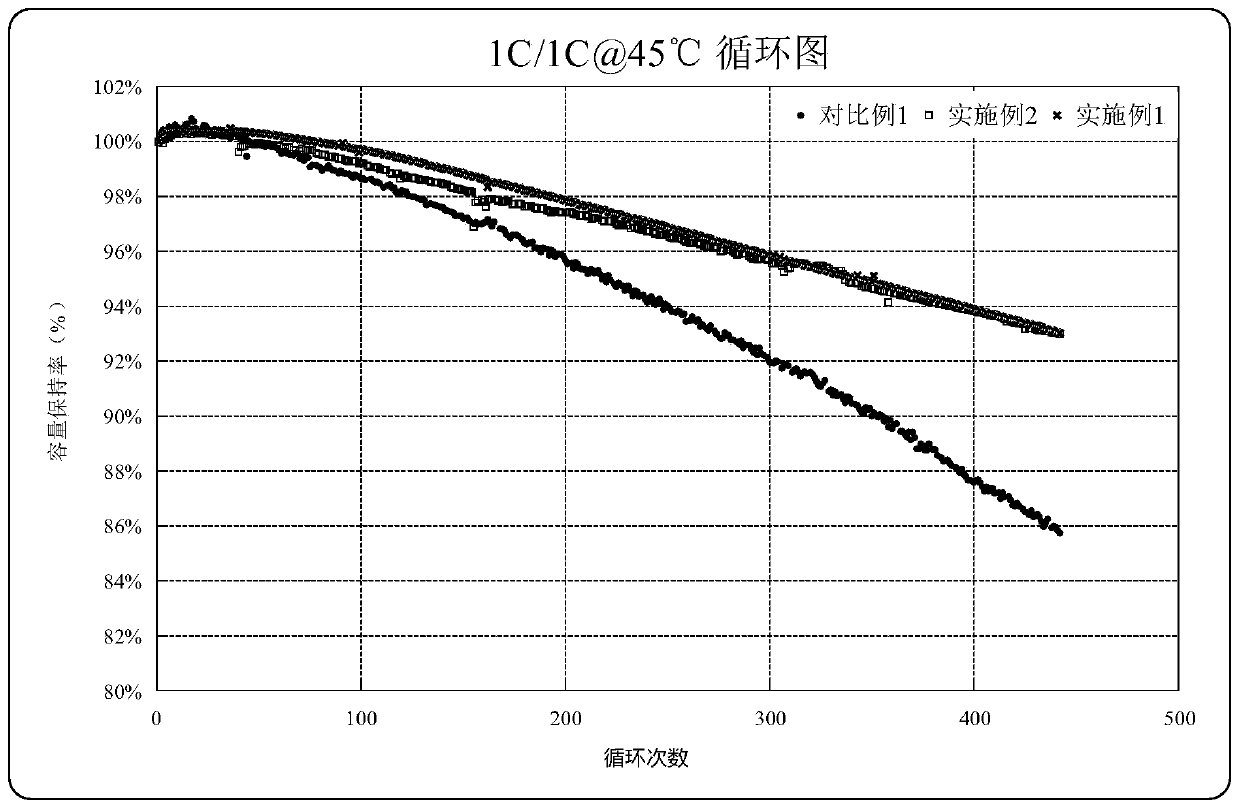

Embodiment 1

[0034] The first step: use the Z-shaped lamination process for battery production, assemble the battery cells, bake them, and inject liquid;

[0035] Step 2: After the liquid injection, perform the first aging of the battery cell, and perform aging at 45°C for 24 hours to ensure sufficient infiltration of the pole piece;

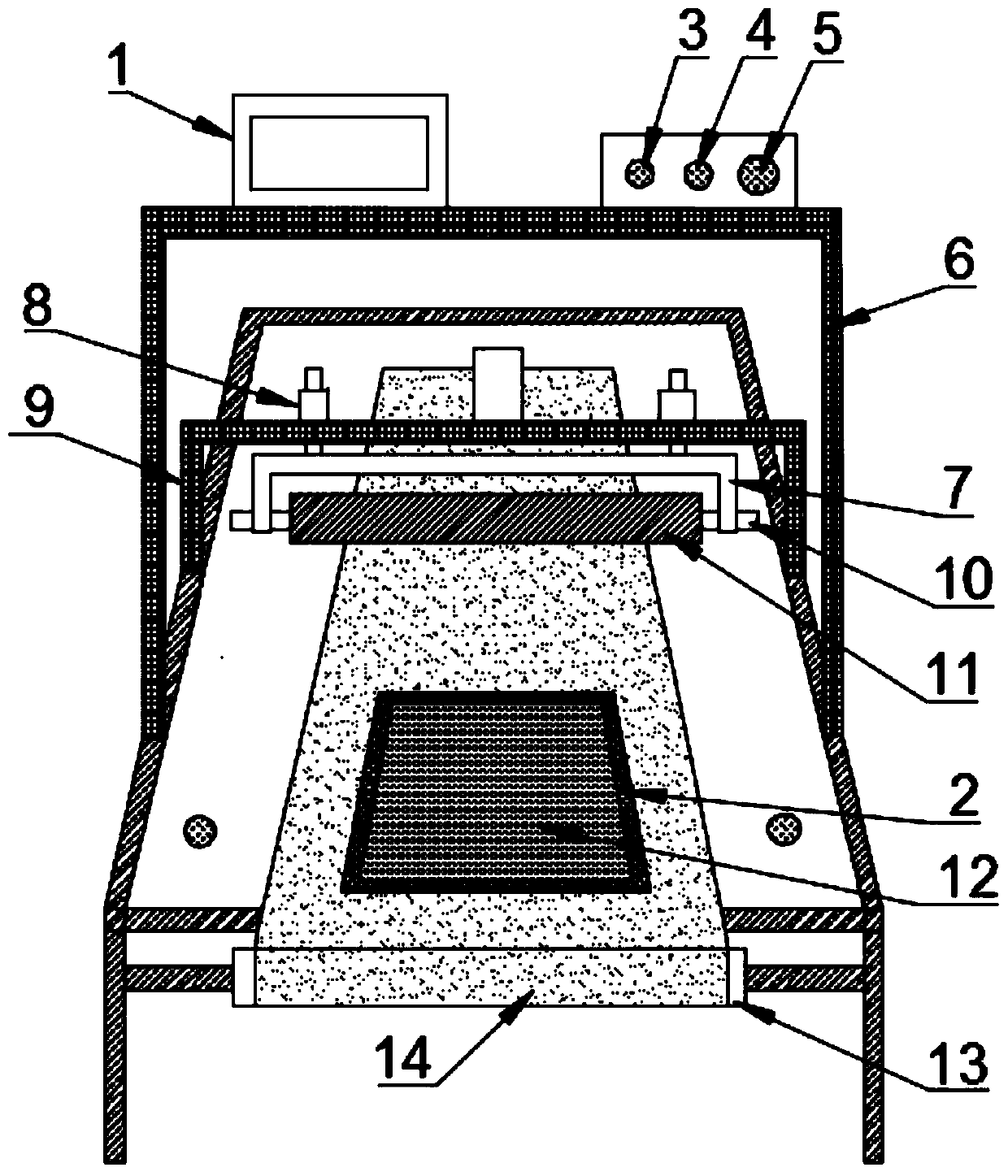

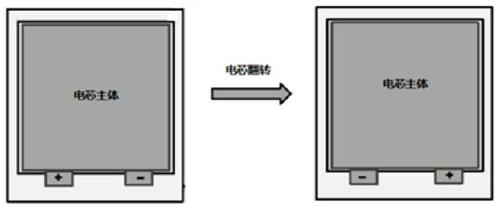

[0036] Step 3: Put the main body of the battery cell into the rolling tool, adjust the pressure and speed of the rolling, and roll the battery after the first aging. The rolling pressure is 0.3MPa, and the rolling speed is 0.1m / s , the direction of rolling is perpendicular to the length direction of the battery tabs (that is, the rolling is carried out along the MD direction of the diaphragm), and the tabs of the battery core are exposed to prevent damage to the tabs caused by rolling to the tabs of the battery core Appearance, rolling tooling and placement of batteries, please refer to figure 1 As shown, when rolling, first roll the front of the cell, and ...

Embodiment 2

[0040] The first step: use the Z-shaped lamination process for battery production, assemble the battery cells, bake them, and inject liquid;

[0041] Step 2: After the liquid injection, perform the first aging of the battery cell, and perform aging at 45°C for 24 hours to ensure sufficient infiltration of the pole piece;

[0042] Step 3: Put the main body of the battery cell into the rolling tool, adjust the pressure and speed of the rolling, and roll the battery after the first aging. The rolling pressure is 0.4MPa, and the rolling speed is 0.2m / s , the direction of rolling is perpendicular to the direction of the battery tab (that is, the rolling is carried out along the MD direction of the diaphragm), and the tab of the battery cell is exposed to prevent the tab from being damaged due to rolling to the tab of the battery cell , rolling tooling and placement of batteries, please refer to figure 1 As shown, when rolling, first roll the front of the cell, and the rolling roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com