Array substrate, manufacturing method thereof and display device

A technology of array substrates and capacitor plates, which is applied in the fields of instruments, nonlinear optics, optics, etc., can solve problems affecting the display panel display, etc., and achieve the effects of increasing capacity, improving product picture quality, and improving display uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

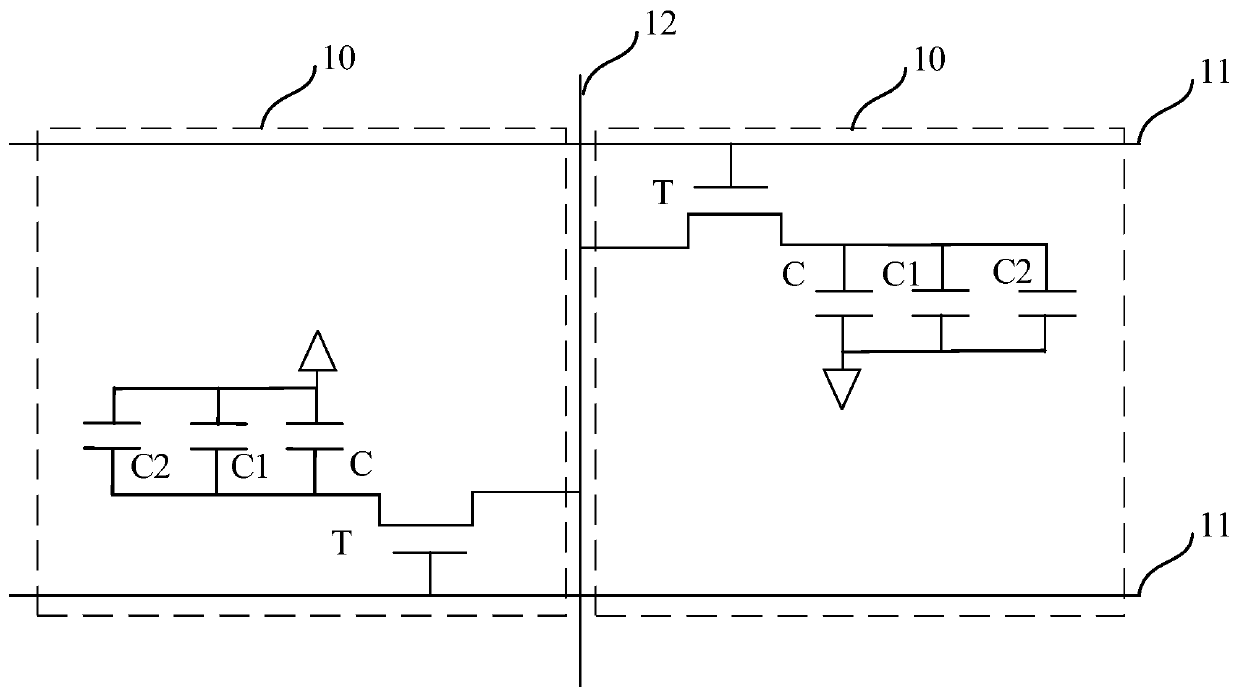

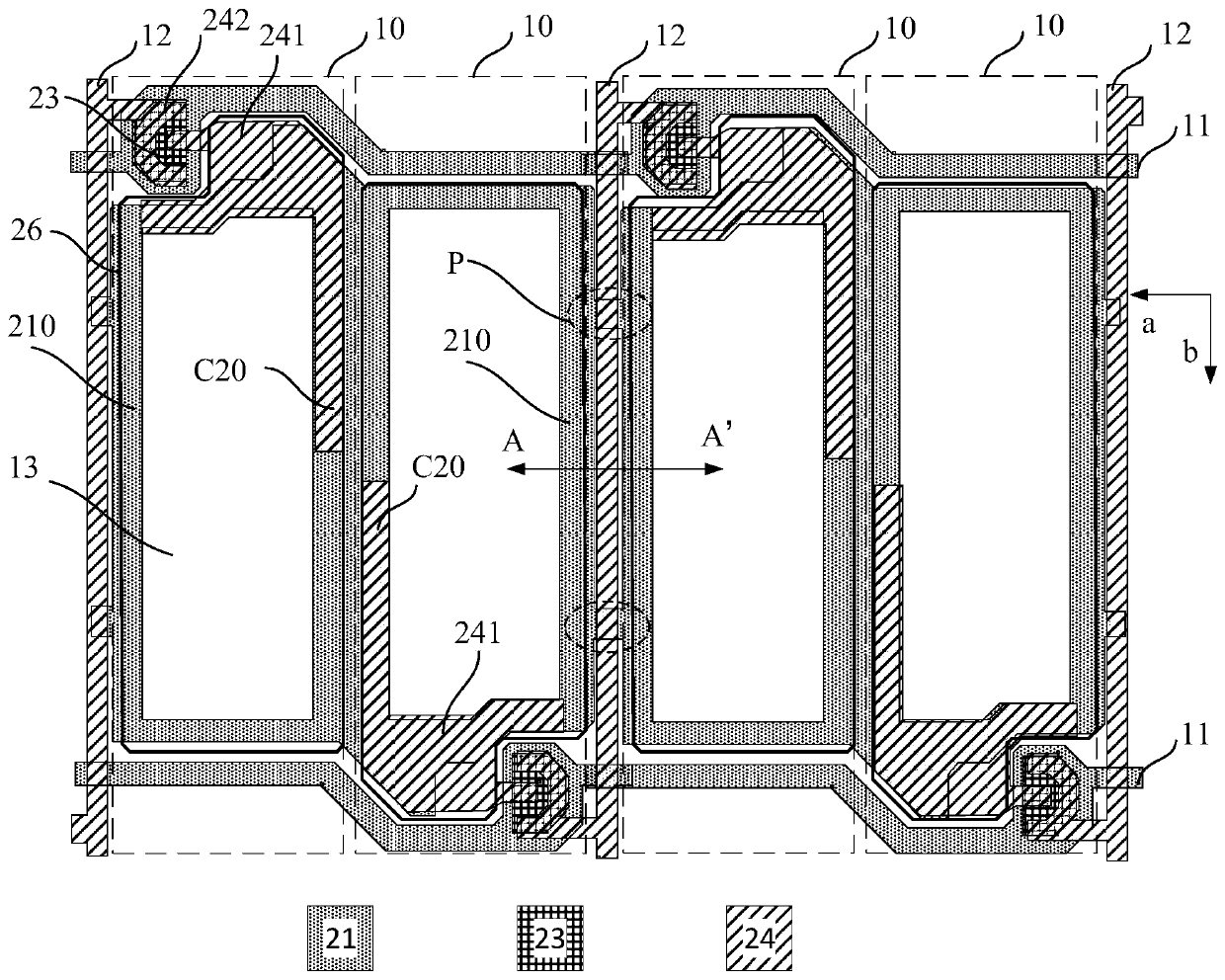

[0060] figure 1 is a schematic circuit diagram of an array substrate provided by an embodiment of the present disclosure. The array substrate is a double grid line array substrate. Such as figure 1 As shown, the array substrate has a plurality of sub-pixels 10. In the double grid line array substrate, these sub-pixels 10 are divided into multiple pairs, and each pair of sub-pixels 10 includes two adjacent sub-pixels 10 (usually two adjacent in the row direction) sub-pixels 10). The two sub-pixels 10 of each pair of sub-pixels 10 are connected to the same data line 12, and are respectively located on both sides of the data line 12; each pair of sub-pixels 10 corresponds to two gate lines 11, and each sub-pixel 10 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com