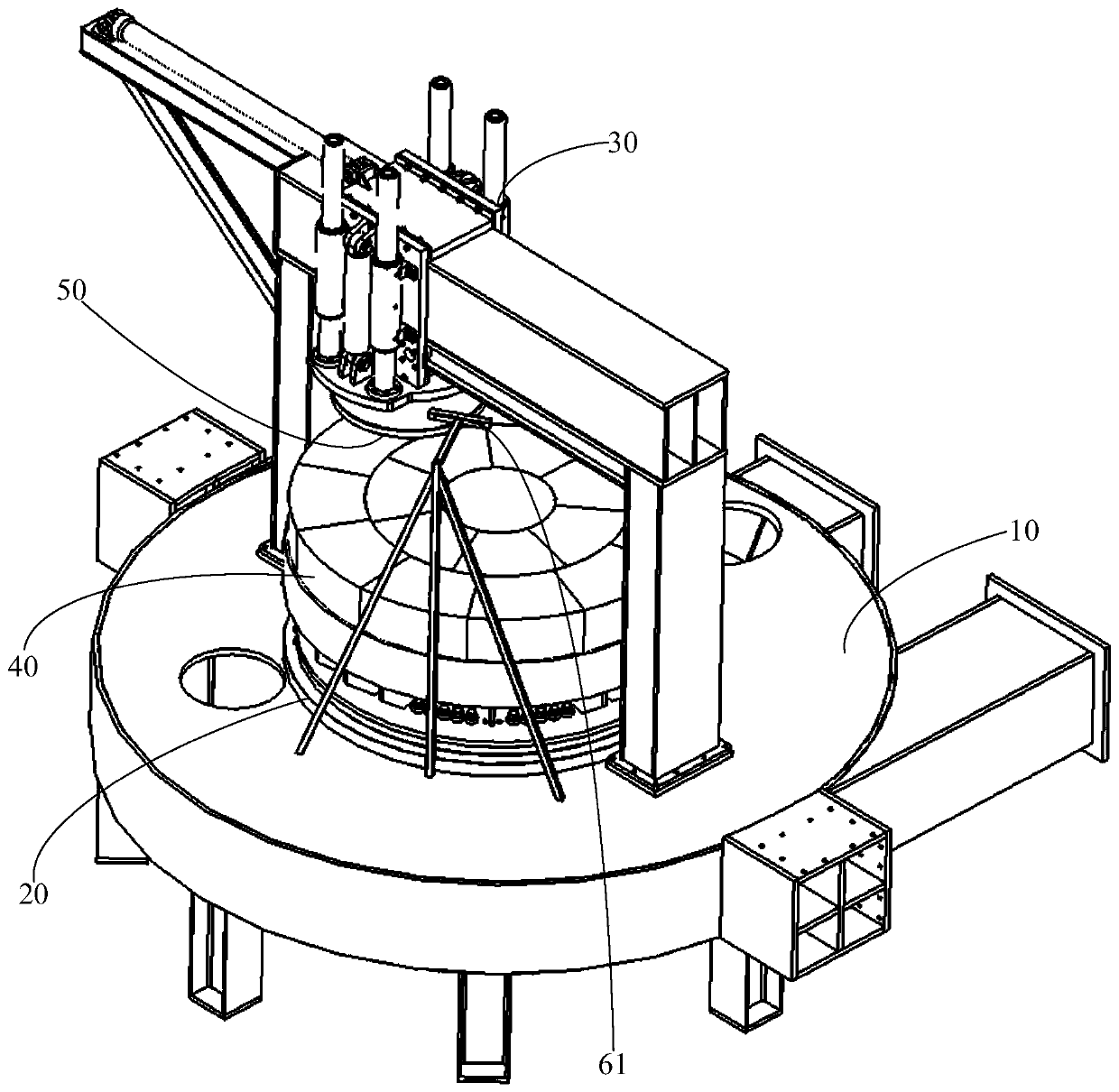

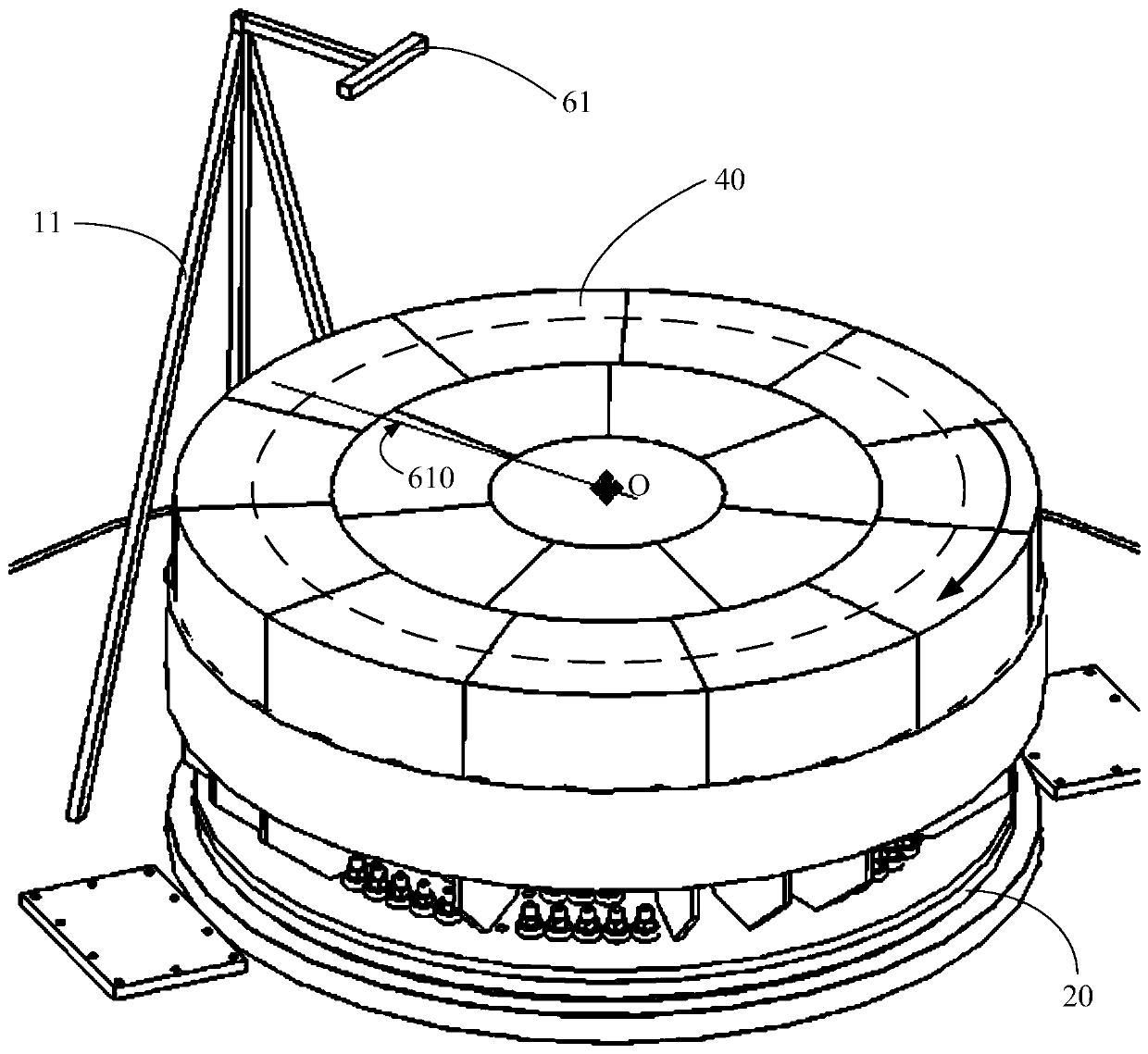

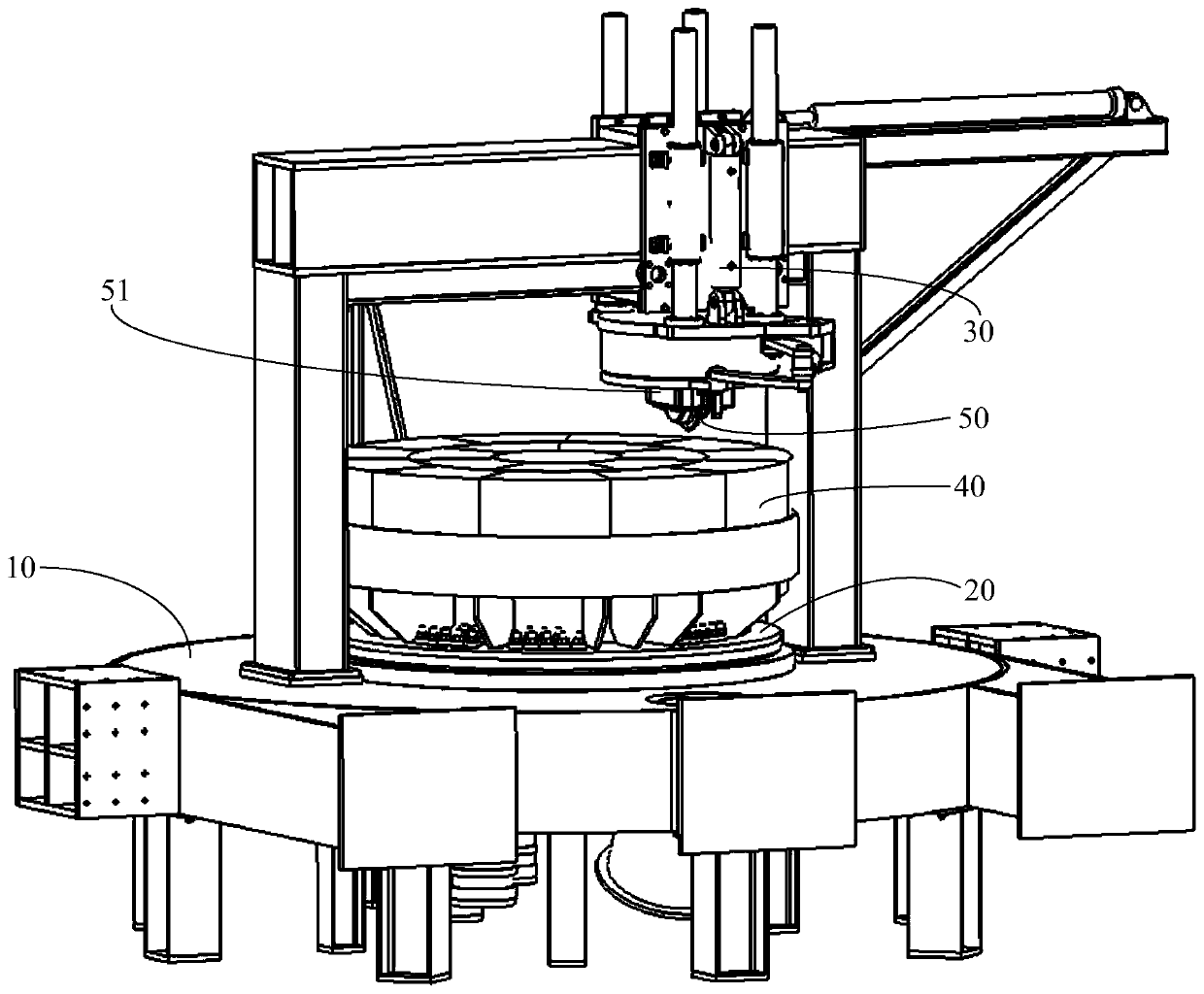

Laser scanning measurement device and method for tool cutting test platform

A laser scanning and cutting test technology, which is applied in the direction of measuring devices, optical devices, and testing machinability, can solve the problems of time-consuming and labor-intensive, large measurement errors, etc., and achieve simple structure, easy adjustment, and convenient and fast measurement methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Since the tool cutting test platform needs to measure the contour of the cut stone after each simulated cutting test, in order to judge whether the cutting test parameters can achieve the expected cutting effect, if not, then according to the measurement results, the test The parameters are analyzed and adjusted in order to achieve the best test parameters for actual construction; in addition, in the process of cutting test, it is also necessary to measure the wear of the tool in order to obtain the service life of each tool under different cutting conditions , to facilitate timely replacement of the tool in actual construction.

[0039] The traditional method of measuring the contour of a stone usually needs to move the stone during the measurement process, so it is only suitable for the measurement of smaller stones; the traditional method of measuring the tool needs to be disassembled before the measurement can be started. The measurement process More troublesome. M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com