Energy recovery gas-liquid two-phase circulating cooling system

An energy recovery and cooling system technology, applied in the field of high temperature component cooling, can solve the problems of low heat resource recovery and utilization efficiency, complex structure of water cooling system, limited heat capacity, etc. Inflow smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

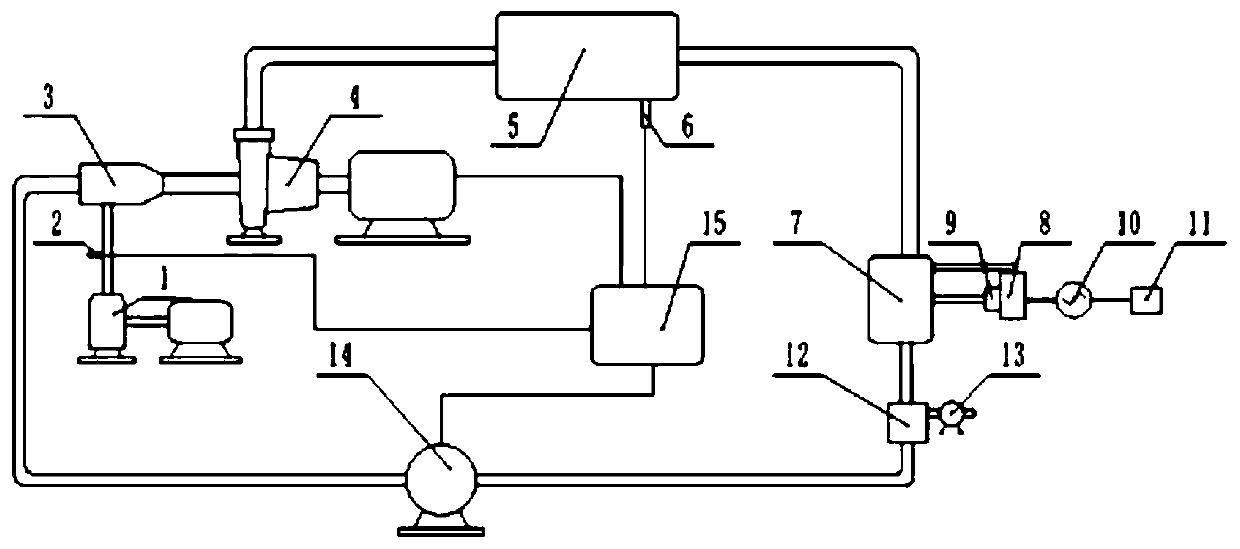

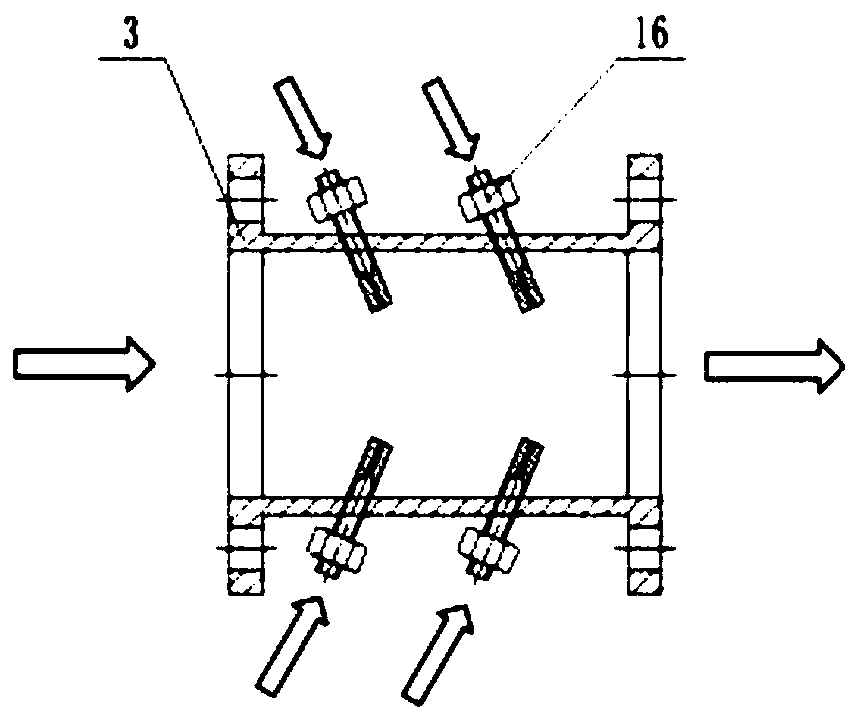

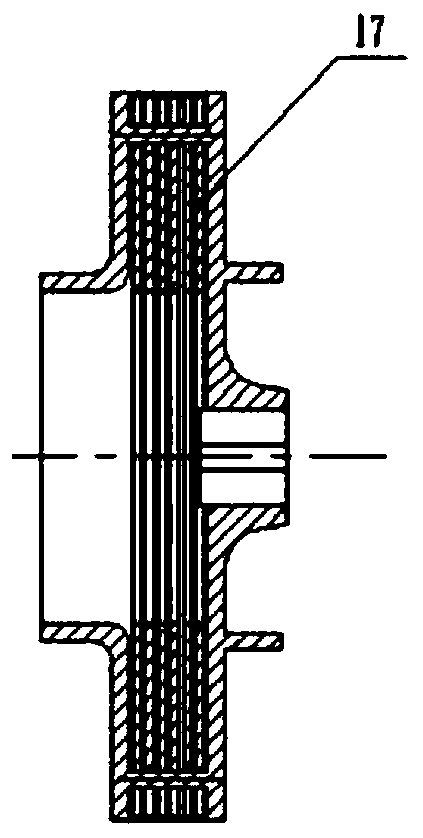

[0024] combine figure 1 , an energy recovery gas-liquid two-phase circulating cooling system provided in this embodiment includes: a first compressor 1, a gas flow controller 2, a gas-liquid mixer 3, an atomizing pump 4, a cooling zone 5, and a temperature sensor 6 , tube-fin heat exchanger 7, expander 8, compressor 9, generator 10, battery 11, gas-liquid separator 12, air pump 13, liquid delivery pump 14, controller 15. The outlet of the first compressor 1 is connected to the gas flow controller 2 and the inlet pipe of the gas-liquid mixer 3 through the gas pipeline, the gas-liquid mixer 3 is connected to the inlet of the atomizing pump 4 through the gas-liquid mixing pipeline, and the outlet of the atomizing pump 4 passes through The gas-liquid mixing pipeline is connected to the inlet of the cooling zone 5, the cooling zone 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com