An uplift-resistant table ring groove excavation device for uplift-resistant piles

A technology of excavating device and anti-uplift pile, which is applied in the field of excavating device for anti-pulling table ring grooves, and can solve the problems of excavating ring grooves of anti-pulling table and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

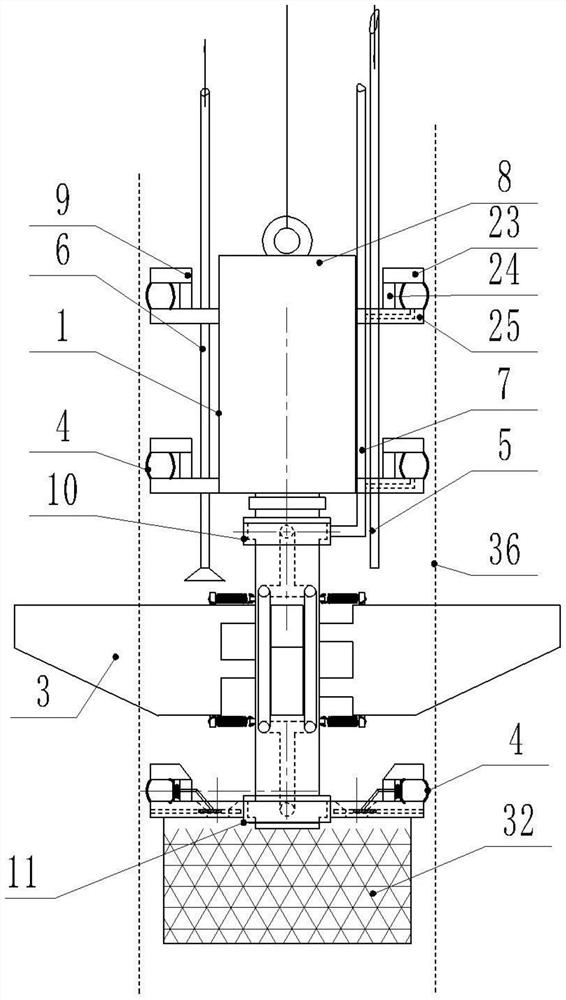

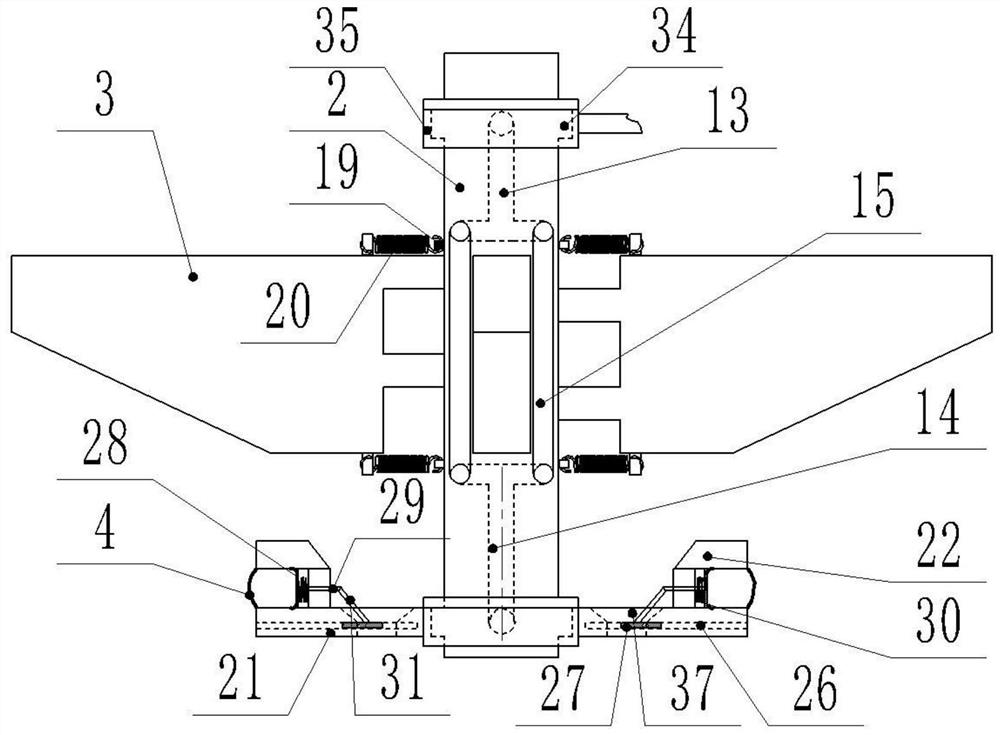

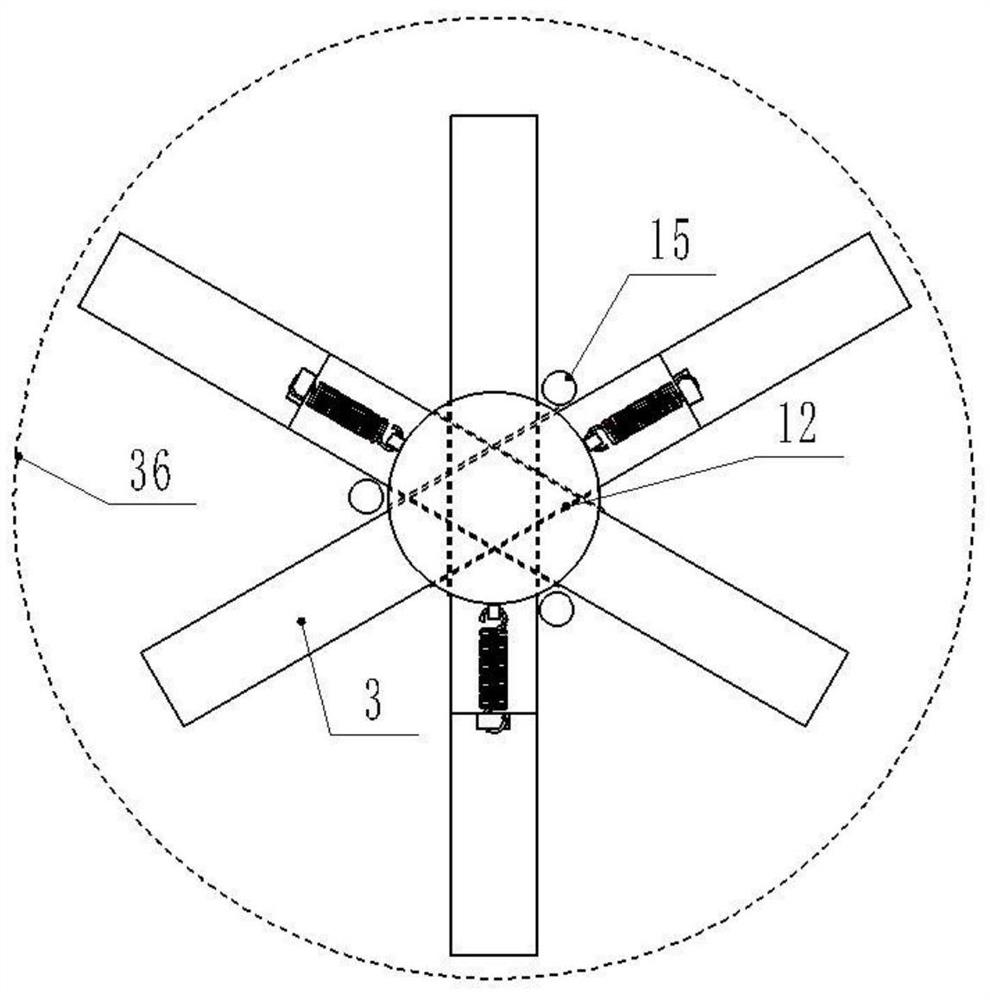

[0038] like Figure 1-7 As shown in the figure, an anti-uplift table ring groove excavation device for an anti-pull pile of the present invention includes an excavating motor 1, an excavating rotating shaft 2, an excavating fan blade 3, an annular water jacket 4, a water inlet pipe 5, a slurry discharge pipe 6 and an annular water Cover the inlet and outlet pipes 7, the excavation motor 1 adopts a waterproof reducer integrated motor, the excavation motor 1 is arranged vertically, and at least two upper annular water jacket mounting brackets 9 are provided on the body 8 of the excavation motor 1. The annular water jacket 4 is installed on the annular water jacket mounting frame 9, and the lower side of the annular water jacket 4 is fixed on the water jacket lower ring plate 25 in the U-shaped notch around several points; the annular water jacket 4 is made of waterproof canvas It can also be made of some waterproof and wear-resistant polymer fabrics. When the annular water jacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com