Protection method and device for cathode roller after grinding and application

A cathode roller and grinder technology, applied in chemical instruments and methods, crystal growth, electrolysis process, etc., can solve the problem of undiscovered cathode roller protection, and achieve the effect of protecting the surface of the cathode roller and isolating the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

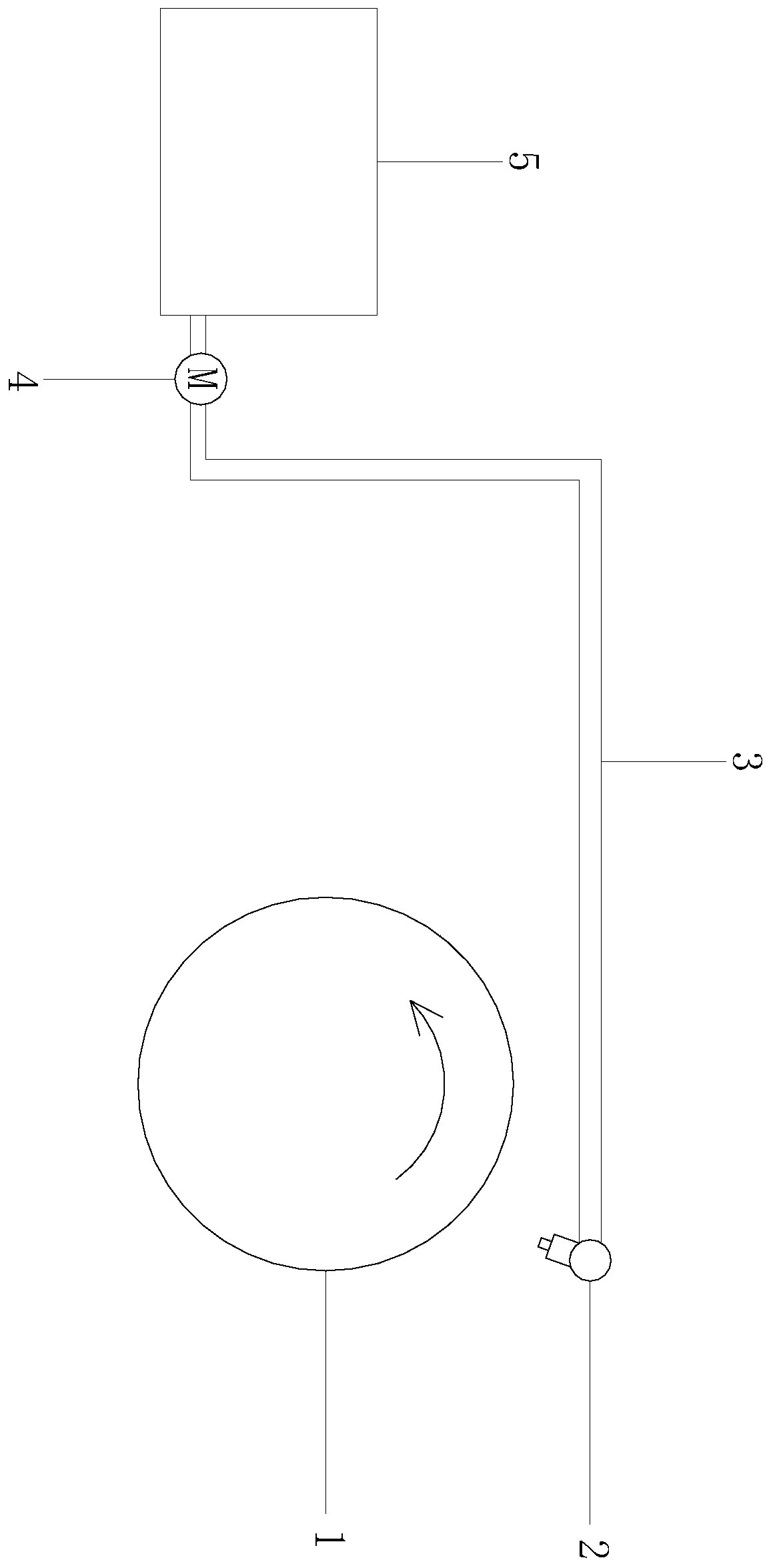

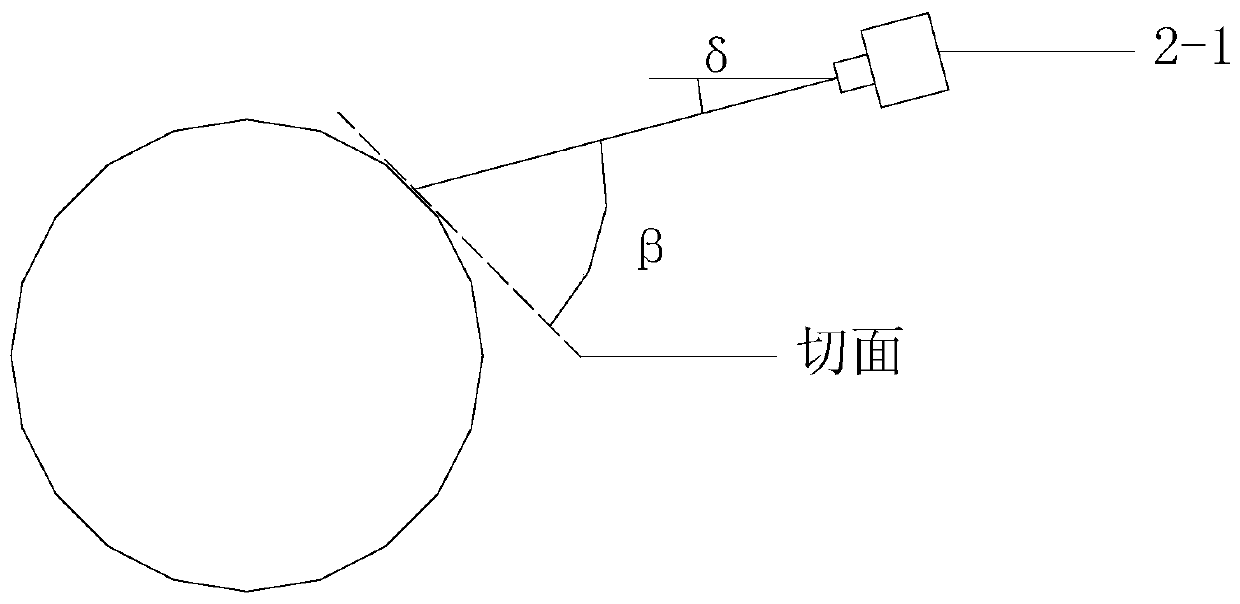

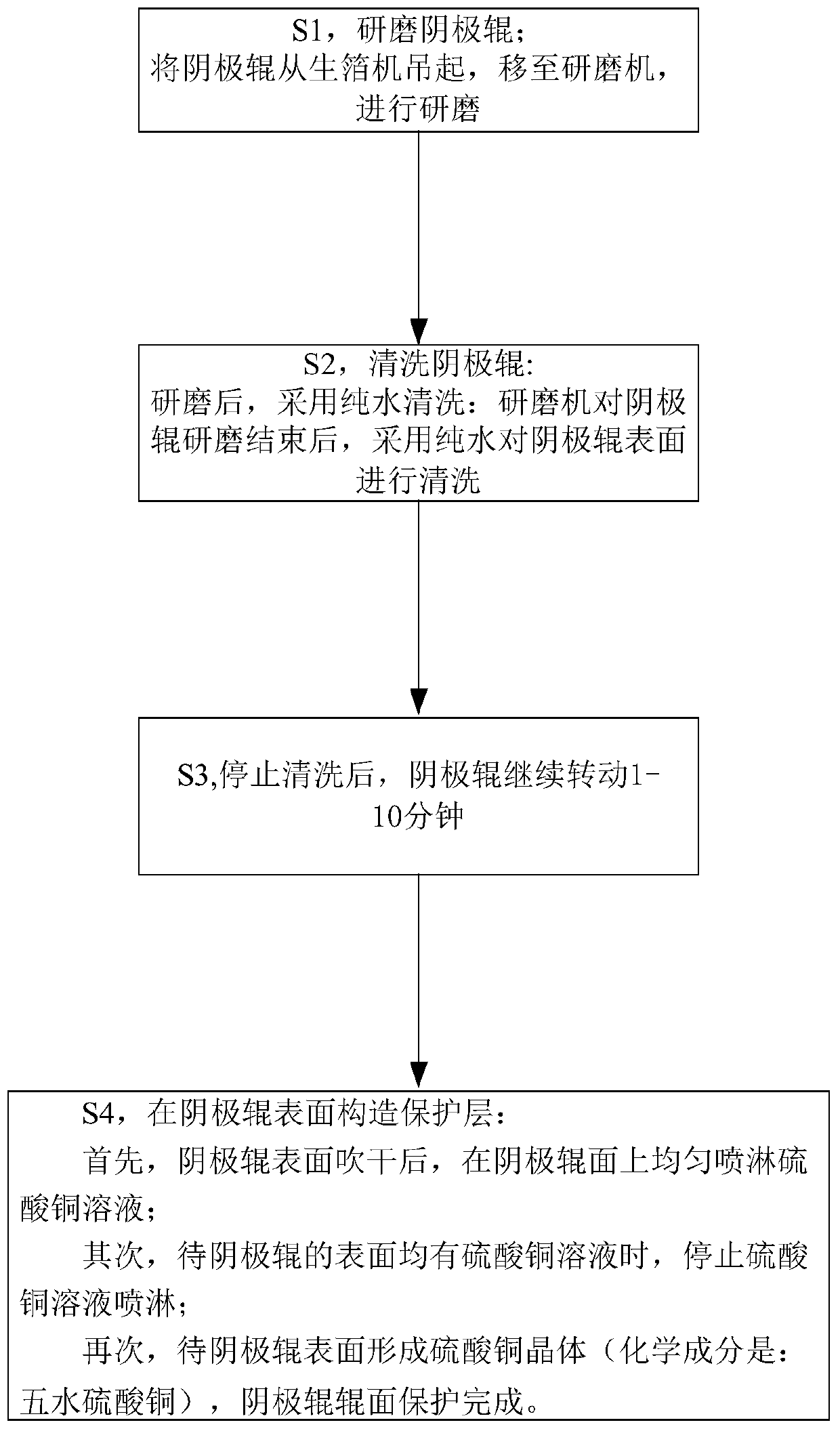

Method used

Image

Examples

Embodiment 1

[0105] After grinding the cathode roll with a width of 1.4m and a diameter of 2.7m, it is protected.

[0106] After cleaning and drying the cathode roller with pure water, spray copper sulfate solution on the cathode roller with a spraying device.

[0107] See the table below for specific parameters.

[0108] Table 1

[0109]

[0110] The cathode roller of Example 1, after the protective layer is formed, is hoisted into the anode tank, and the copper sulfate electrolyte circulation is started after installation. After the copper sulfate crystals on the surface of the cathode roller are melted, no oxide layer is found on the surface, and the cathode roller is used No quality problems such as color difference were found in the stripped copper foil.

Embodiment 2

[0119] After grinding the cathode roll with a width of 1.4m and a diameter of 2.7m, it is protected.

[0120] After cleaning and drying the cathode roller with pure water, spray copper sulfate solution on the cathode roller with a spraying device.

[0121] See the table below for specific parameters.

[0122] table 3

[0123]

[0124] The cathode roll of embodiment 2, after the protective layer is formed, is hoisted to the anode tank, and after installation, the copper sulfate electrolyte is circulated. After the copper sulfate crystals on the surface of the cathode roll are dissolved into the copper sulfate electrolyte, no oxidation is found on the surface. Layer, using the copper foil peeled off from the cathode roller, no quality problems such as color difference were found.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com