Method for improving absorptivity of chrome tanning agent in tanning process through microwave irradiation pretreatment

A technology of microwave irradiation and chrome tanning agent, applied in chemical/physical process, chemical/physical/physical-chemical process, chemical/physical/physical-chemical process of applying energy, etc., to reduce production cost, reduce sewage treatment load and Cost and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

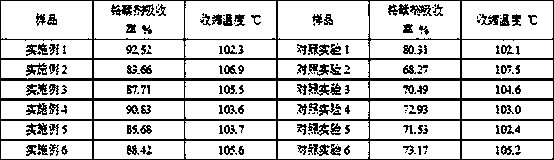

Examples

Embodiment 1

[0013] Dissolve chrome tanning agent with a basicity of 0% in water to prepare Cr 2 o 3 The chrome tanning solution with a concentration of 5g / L; under the condition of stirring, microwave irradiation with a frequency of 915MHz is used to raise the temperature to 30°C, and stir and keep warm at this temperature for 60min; then add the chrome tanning solution treated by microwave irradiation into the Drum, and add sodium chloride to make the concentration of neutral salt in the tanning solution 90g / L; turn the drum until the neutral salt is completely dissolved, put in the pickled bare hide, the weight of the bare hide is 200% of the weight of the tanning solution, and then press The chrome tanning is carried out by the conventional method, and the parameters such as the amount of tanning agent, liquid ratio, temperature, time and pH value during the chrome tanning process are the same as those of conventional chrome tanning.

Embodiment 2

[0015] Dissolve the chrome tanning agent with a basicity of 33% in water to prepare Cr 2 o 3 The chrome tanning solution with a concentration of 20g / L; under the condition of stirring, microwave irradiation with a frequency of 2450MHz is used to raise the temperature to 40°C, and stir and keep warm at this temperature for 150min; then add the chrome tanning solution treated by microwave irradiation into the Drum, and add sodium chloride to make the concentration of neutral salt in the tanning solution 60g / L; turn the drum until the neutral salt is completely dissolved, put in pickled hides, the weight of the bare hide is 100% of the weight of the tanning solution, and then press The chrome tanning is carried out by the conventional method, and the parameters such as the amount of tanning agent, liquid ratio, temperature, time and pH value during the chrome tanning process are the same as those of conventional chrome tanning.

Embodiment 3

[0017] Dissolve the chrome tanning agent with a basicity of 42% in water to prepare Cr 2 o 3 The chrome tanning solution with a concentration of 10g / L; under the condition of stirring, microwave irradiation with a frequency of 2450MHz is used to raise the temperature to 50°C, and stir and keep warm at this temperature for 45min; then add the chrome tanning solution treated by microwave irradiation into the Drum, and add sodium sulfate to make the concentration of neutral salt in the tanning solution 70g / L; turn the drum until the neutral salt is completely dissolved, put in the pickled bare hide, the weight of the bare hide is 150% of the weight of the tanning solution, and then press the conventional Methods Chrome tanning was carried out, and the parameters such as tanning agent dosage, liquid ratio, temperature, time and pH value during the chrome tanning process were the same as those of conventional chrome tanning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com