Fluorescent powder quantum dot composite particles as well as preparation method and application thereof

A technology of composite particles and phosphors, which is applied in the field of white light LEDs, can solve the problems of uneven distribution of phosphors and quantum dots, optical inconsistency, etc., to ensure optical consistency, sufficient positive or negative modification of the surface, and parameters Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

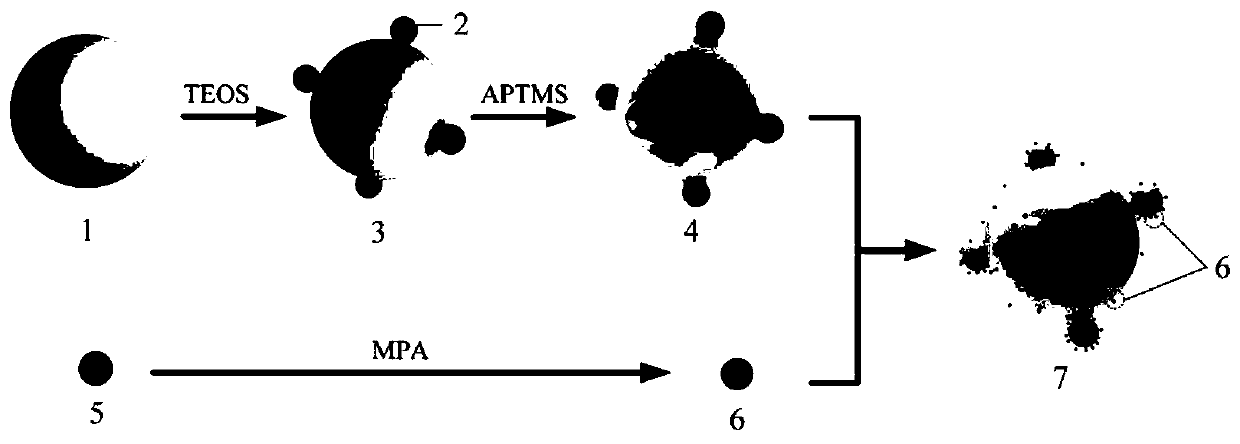

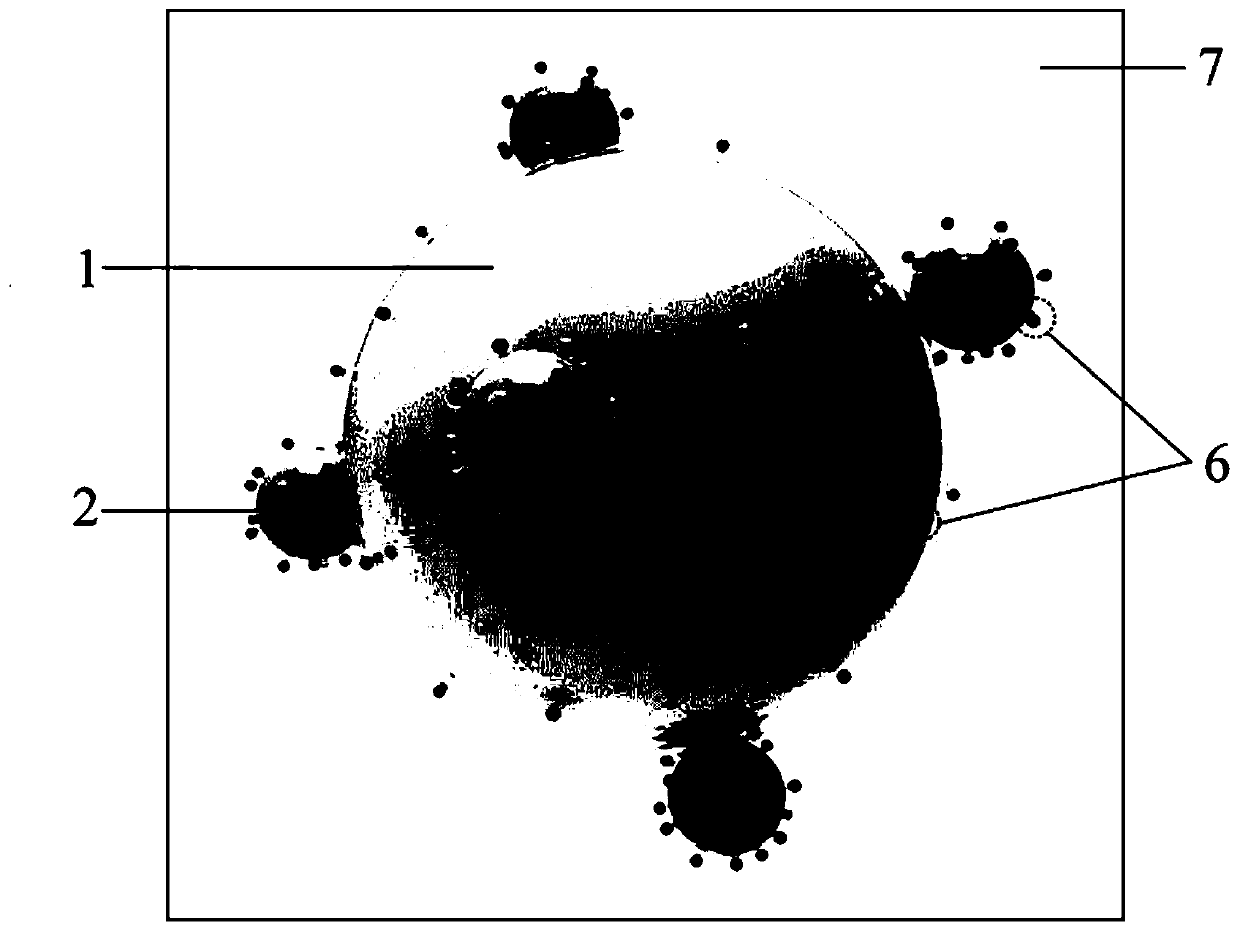

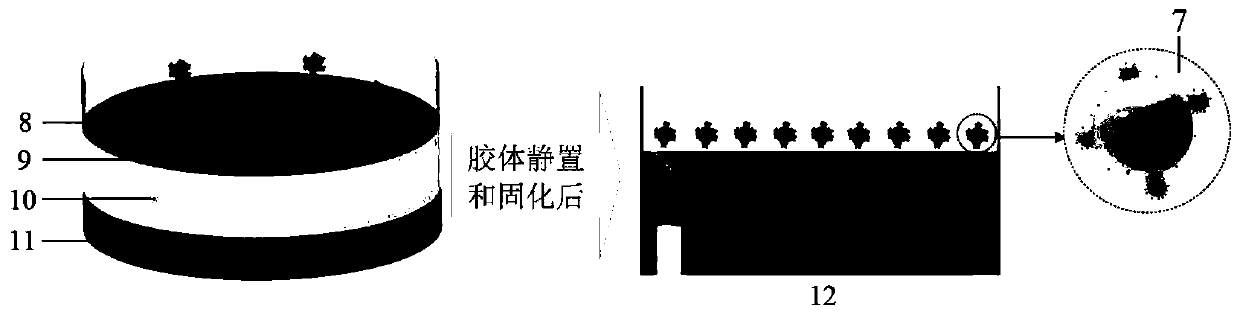

[0038] like figure 1 As shown, the embodiment of the present invention provides a method for preparing phosphor quantum dot composite particles, the method comprising the following steps:

[0039] S1 utilizes the hydrolysis of tetraethyl orthosilicate (TEOS) to prepare silica 2 on the surface of phosphor 1 to form a composite structure of phosphor-silicon dioxide 3, specifically including the following sub-steps:

[0040] S11 adding fluorescent powder, tetraethyl orthosilicate, ammonia water and deionized water to the alcohol solution to obtain a mixed solution, the concentration of ammonia water is 20% to 30%;

[0041] S12 heating the mixed solution while stirring for a preset time, so that tetraethyl orthosilicate is hydrolyzed and silicon dioxide is generated on the surface of the phosphor;

[0042] S13 After the reaction is completed, the solid precipitate is washed with an alcohol solution to prepare phosphor-silicon dioxide;

[0043]S2 positively modifies the surface o...

Embodiment 1

[0059] S11 Add fluorescent powder, tetraethyl orthosilicate, ammonia water and deionized water to the ethanol solution to obtain a mixed solution. The concentration is 0.8mol / L;

[0060] S12 heating the mixed solution to 40° C. while stirring for 1 h, so that tetraethyl orthosilicate is hydrolyzed and silicon dioxide is formed on the surface of the phosphor;

[0061] S13 After the reaction is completed, the solid precipitate is washed with an ethanol solution to obtain phosphor-silicon dioxide;

[0062] S21 adds phosphor-silicon dioxide and 3-aminopropyltrimethoxysilane into the ethanol solution according to a mass ratio of 1:10 to obtain a prefabricated solution, and ensures that the concentration of 3-aminopropyltrimethoxysilane in the prefabricated solution is 2mol / L, and then stirred for 6h so that the branched chain with amino group produced by the hydrolysis of 3-aminopropyltrimethoxysilane is adsorbed on the surface of the phosphor-silica, thereby positively modifying ...

Embodiment 2

[0068] S11 Add fluorescent powder, tetraethyl orthosilicate, ammonia water and deionized water to the methanol solution to obtain a mixed solution. The concentration is 0.5mol / L;

[0069] S12 heating the mixed solution to 60° C. while stirring for 45 minutes, so that tetraethyl orthosilicate is hydrolyzed and silicon dioxide is formed on the surface of the phosphor;

[0070] S13 After the reaction is completed, the solid precipitate is washed with a methanol solution to prepare phosphor-silicon dioxide;

[0071] S21 adds phosphor-silicon dioxide and 3-aminopropyltrimethoxysilane to the methanol solution at a mass ratio of 1:5 to obtain a prefabricated solution, and ensures that the concentration of 3-aminopropyltrimethoxysilane in the prefabricated solution is 1.5mol / L, then stirred for 8 hours to make the branched chains with amino groups generated by the hydrolysis of 3-aminopropyltrimethoxysilane adsorbed on the surface of the phosphor-silica, thereby positively modifying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com