An elevator traction system

An elevator traction and traction sheave technology, applied in the elevator field, can solve the problems of increasing the friction force between the wire rope and the traction sheave, increasing the wear of the wire rope, increasing the friction force between the wire rope and the traction sheave, etc., and achieving a good oil pollution cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

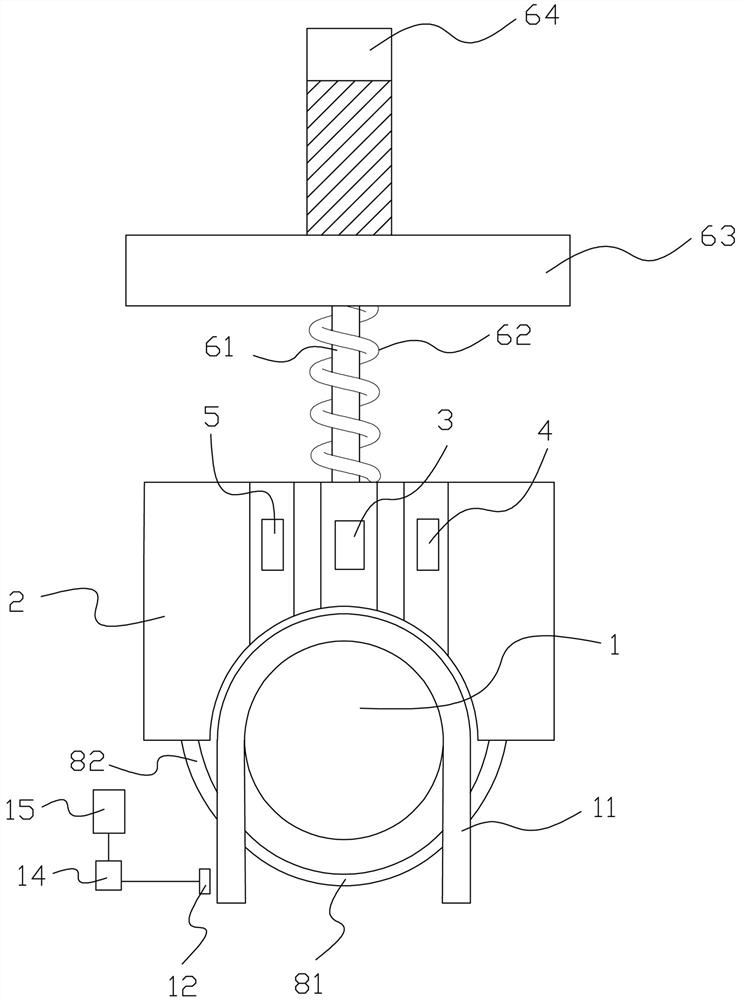

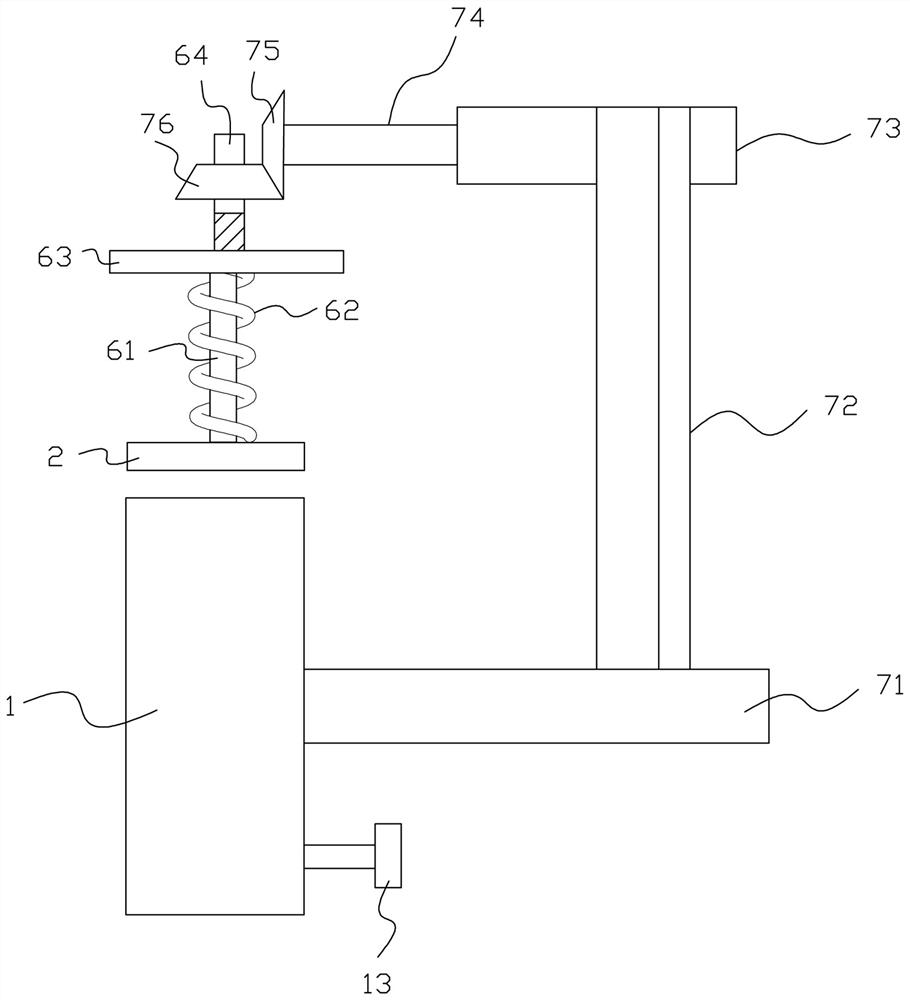

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , the elevator traction system in this embodiment includes a traction sheave 1, a brake for braking the traction sheave 1, a traction rope 11 wound on the traction sheave 1, and is used to detect the traction rope 11 in real time. The diameter detecting part, the pressing block 2 arranged above the traction rope 11, the oil stain cleaning part arranged in the pressing block 2 to clean the oil stain on the surface of the traction rope 11, and the diameter detecting part, oil stain The controller 15 of the cleaning part, the lower end of the briquetting block 2 is an arc shape matched with the wheel groove of the traction sheave 1, the upper end of the briquetting blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com