Cleaning system

A cleaning system and a technology to be cleaned, applied in the field of cleaning systems, can solve the problems of not being able to completely remove sodium, increasing the difficulty of cleaning equipment with sticky sodium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Taking the sodium valve as an example, a cleaning method in the embodiment of the present invention is further described.

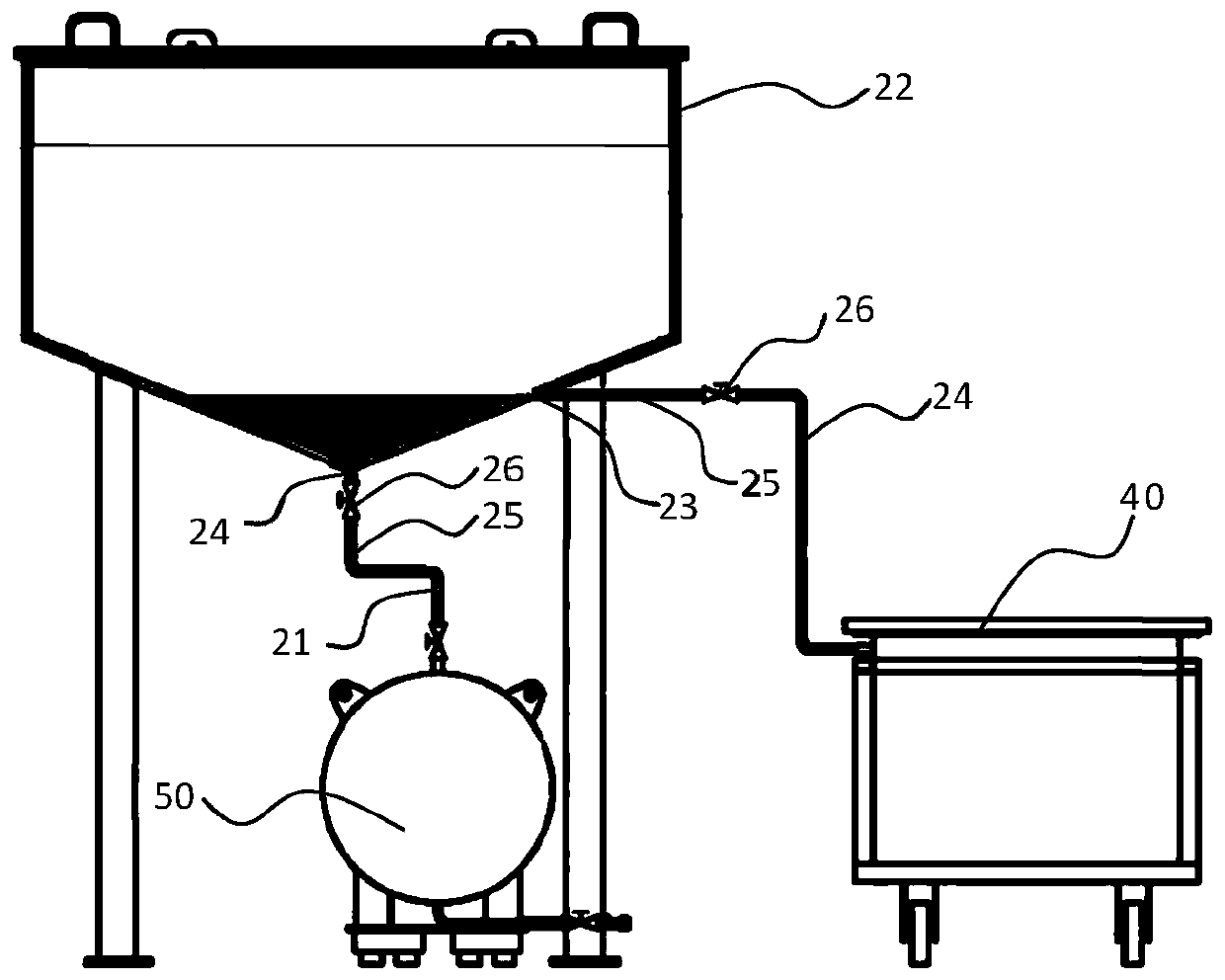

[0040] Move the equipment to be cleaned to the transport module 10 (using a sealable temporary storage tank in this embodiment) by the clamping module 60 (an electric crane is used in this embodiment), and the first cleaning agent is used in the temporary storage tank to cover the equipment to be cleaned. Impurities on the surface of the equipment are sealed in the temporary storage tank and transported to the first cleaning module 20 .

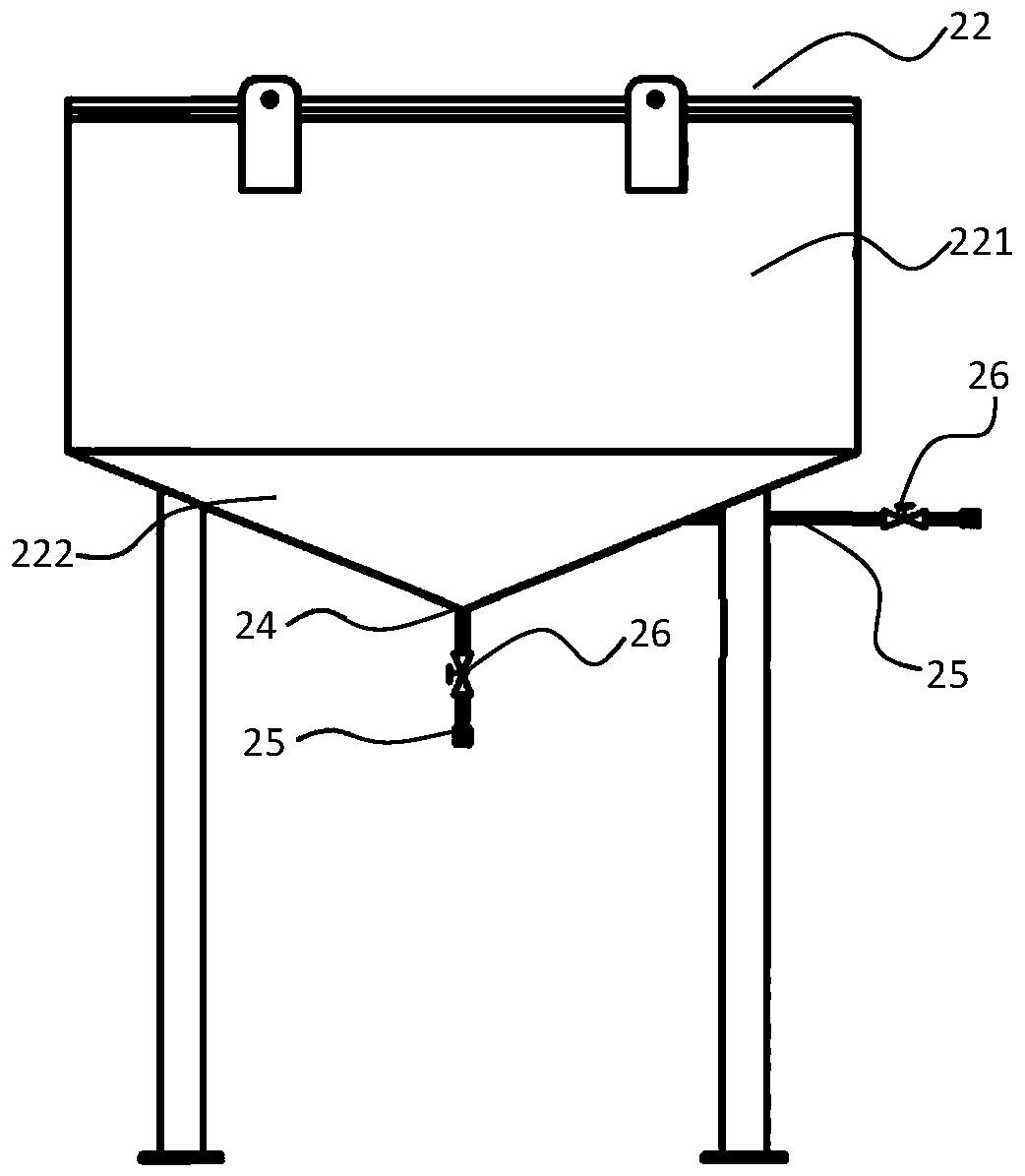

[0041] Add the first cleaning agent (paraffin oil is used in this embodiment) in the cleaning tank 22 of the first cleaning module 20, use an electric crane to transfer the equipment to be cleaned to the cleaning tank 22, and use an electric heating wire to heat the cleaning tank 22, so that impurities Desorb from the surface of the equipment to be cleaned, and drive the equipment to be cleaned to move up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com