Making method of salted goose

A production method, technology of salted goose, applied in the direction of climate change adaptation, food science, etc., can solve the problems of cumbersome pickling steps, no mention of pickled brine recycling, long time consumption, etc., to shorten the pickling time, improve Pickling efficiency and the effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

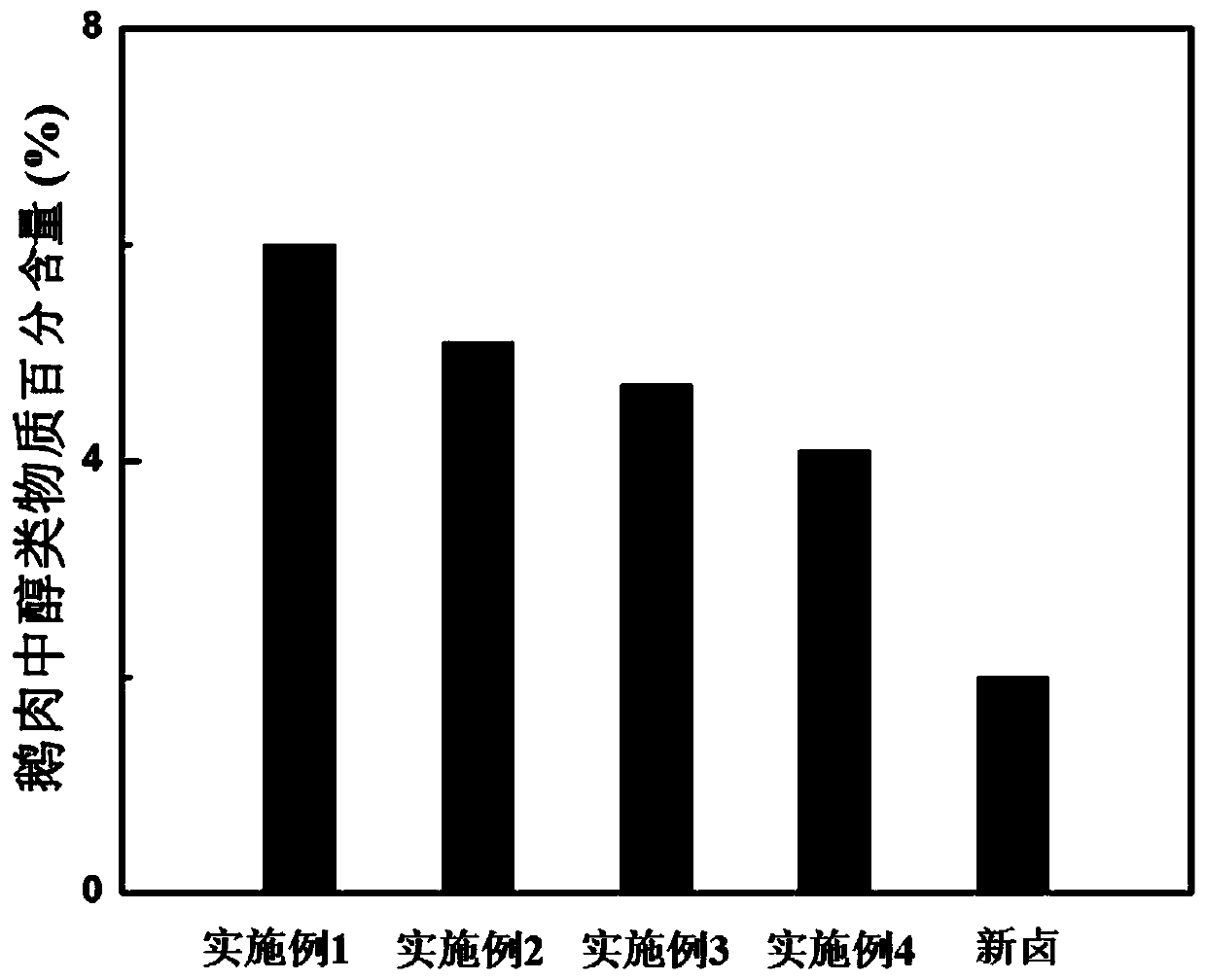

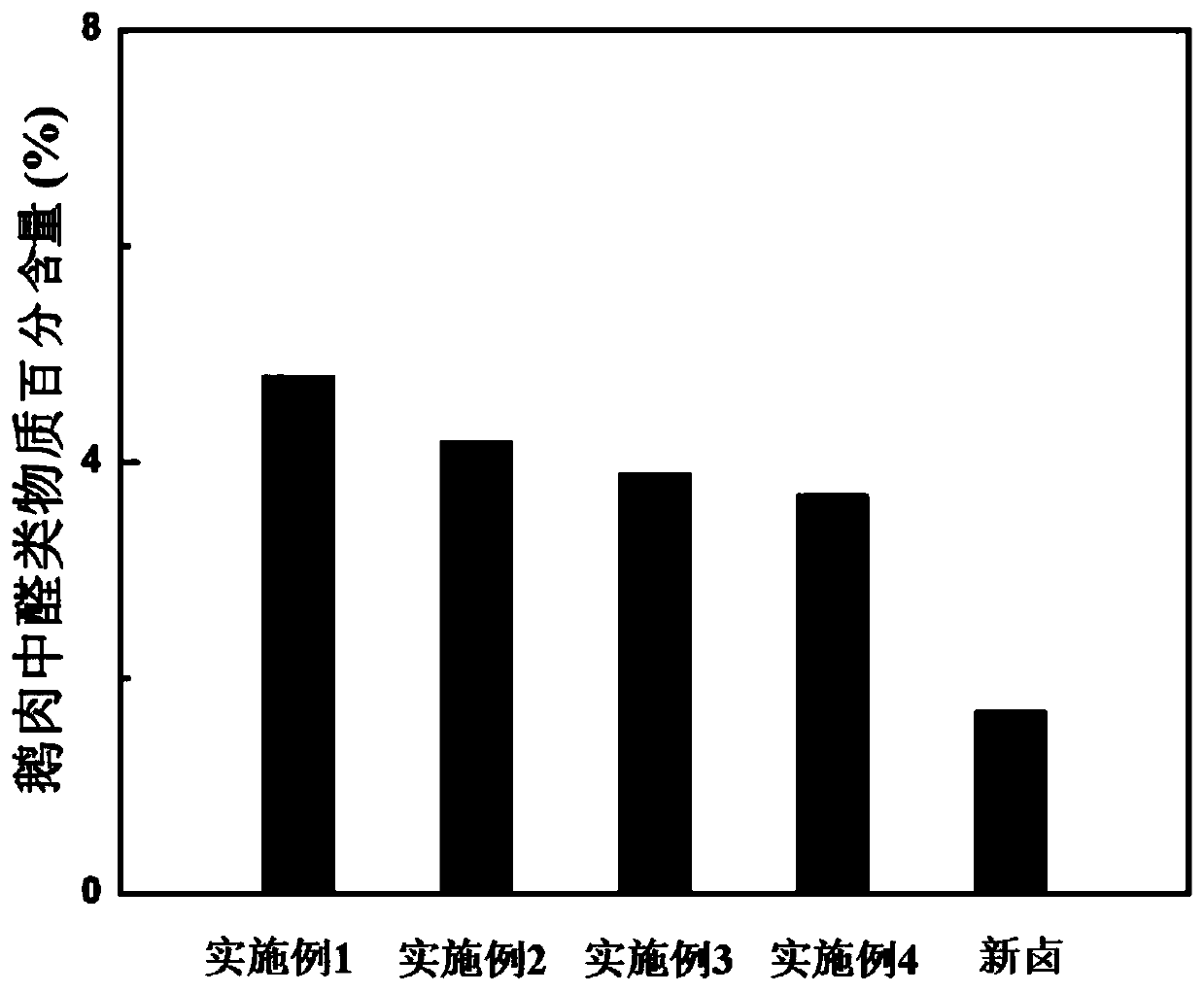

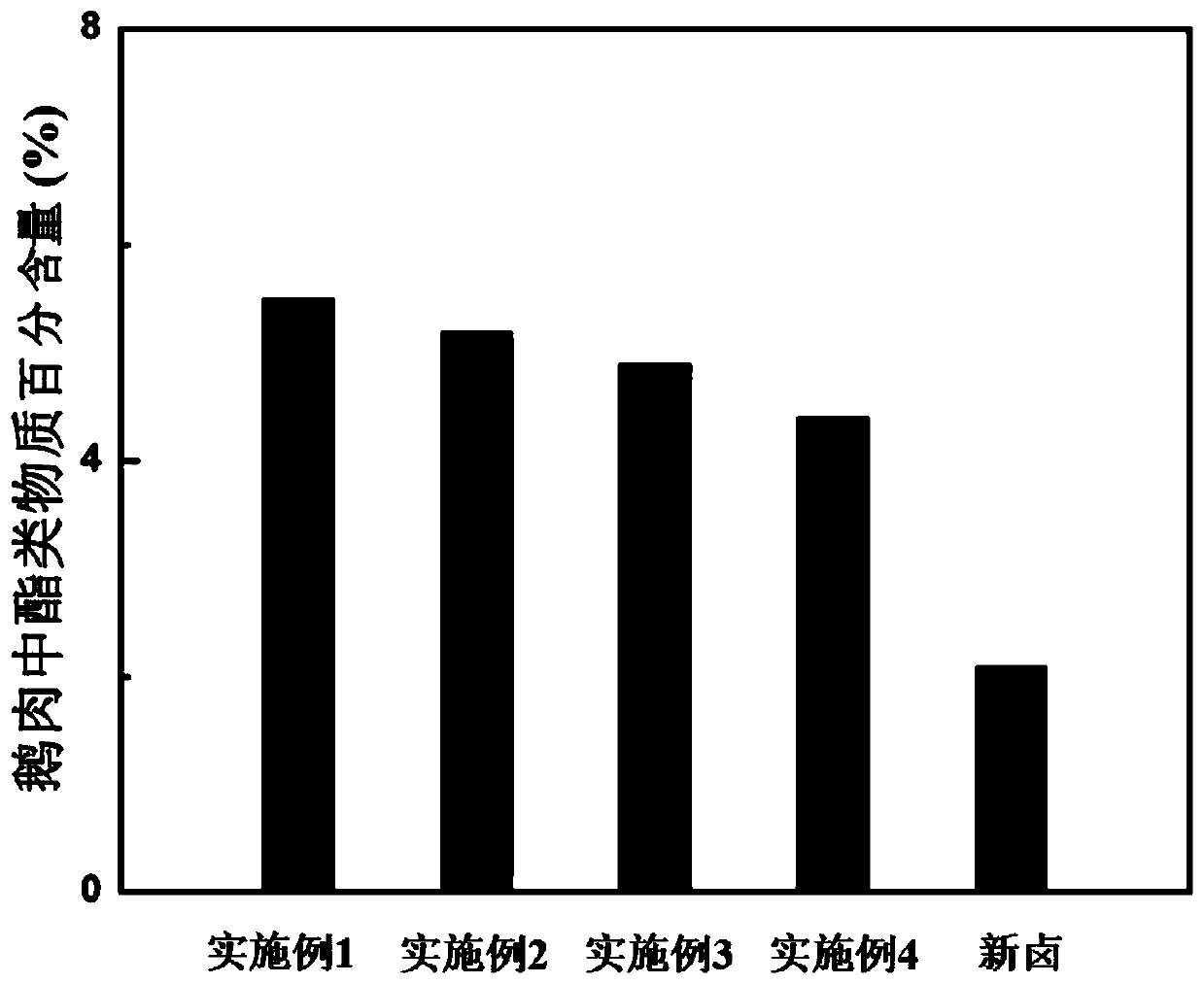

Embodiment 1

[0030] A kind of preparation method of brine goose, specifically comprises the following steps:

[0031] (1) Slaughter the live goose, take out the viscera and clean it, then drain the water

[0032] (2) Completely immerse the cleaned and drained fresh goose in the marinated marinade that has been reused 15 times, and apply 500N pressure on the uppermost layer for 5 hours. The pickled bittern is prepared as follows:

[0033] 5 parts of ginger, 15 parts of green onion, 6 parts of star anise, 6 parts of cinnamon, 5 parts of grass fruit, 15 parts of cumin, 10 parts of cardamom, 8 parts of licorice, 8 parts of Angelica dahurica, 5 parts of fragrant leaves, 7 parts of peppercorns, and 5 parts of cloves , 100 parts of drinking water. First, mix and crush all raw materials except drinking water into 250-mesh powder, wrap it with gauze, boil in drinking water for 8 hours, then add edible salt to form a saturated solution of table salt, and finally cool to room temperature.

[0034]...

Embodiment 2

[0038] A kind of preparation method of brine goose, specifically comprises the following steps:

[0039] (1) Slaughter the live goose, take out the viscera and clean it, then drain the water

[0040] (2) The cleaned and drained fresh goose is completely immersed in the marinated marinade that has been reused 11 times, and a pressure of 500N is applied to the uppermost layer for 5 hours. The pickled bittern is prepared as follows:

[0041] 5 parts of ginger, 15 parts of green onion, 6 parts of star anise, 6 parts of cinnamon, 5 parts of grass fruit, 15 parts of cumin, 10 parts of cardamom, 8 parts of licorice, 8 parts of Angelica dahurica, 5 parts of fragrant leaves, 7 parts of peppercorns, and 5 parts of cloves , 100 parts of drinking water. First, mix and crush all raw materials except drinking water into 250-mesh powder, wrap it with gauze, boil in drinking water for 8 hours, then add edible salt to form a saturated solution of table salt, and finally cool to room temperat...

Embodiment 3

[0046] A kind of preparation method of brine goose, specifically comprises the following steps:

[0047] (1) Slaughter the live goose, take out the viscera and clean it, then drain the water

[0048] (2) The cleaned and drained fresh goose is completely immersed in the marinated marinade that has been reused 8 times, and a pressure of 500N is applied to the uppermost layer for 5 hours. The pickled bittern is prepared as follows:

[0049] 5 parts of ginger, 15 parts of green onion, 6 parts of star anise, 6 parts of cinnamon, 5 parts of grass fruit, 15 parts of cumin, 10 parts of cardamom, 8 parts of licorice, 8 parts of Angelica dahurica, 5 parts of fragrant leaves, 7 parts of peppercorns, and 5 parts of cloves , 100 parts of drinking water. First, mix and crush all raw materials except drinking water into 250-mesh powder, wrap it with gauze, boil in drinking water for 8 hours, then add edible salt to form a saturated solution of table salt, and finally cool to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com