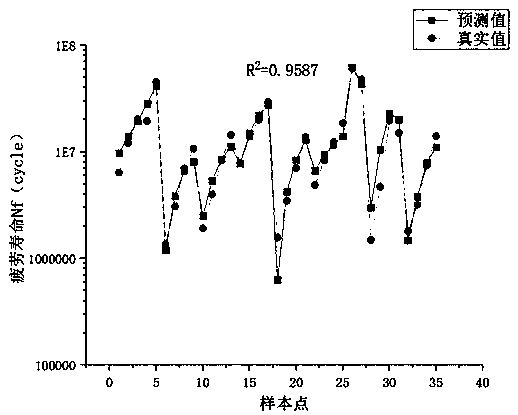

Gear contact fatigue life prediction method based on GA-BP neural network

A BP neural network and GA-BP technology, applied in the field of intelligent manufacturing, can solve the problems of imperfect accumulation theory of fatigue damage, failure to consider the influence of fatigue damage, fatigue damage of dangerous points, etc. The effect of high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] Such as figure 1 As shown, this embodiment includes the following steps:

[0023] S1. Collect the test data of the gear contact fatigue test, and use the gear parameters to analyze the influence of the gear contact fatigue life. The structural characteristic parameters and material parameters of the gear are used as input parameters, and the gear contact fatigue life is used as the output parameter. For each set of test data Perform normalization processing and use it as a training sample and a test sample.

[0024] 143 sets of gear contact fatigue life test data were collected from multiple universities and research institutes. The selected input parameters include but are not limited to the number of teeth, roughness, contact stress, tooth surface hardness and material parameters. The output parameter is the contact fatigue life of the gear. The un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com