Differential angle sensor with multipole magnet

An angle sensor and multi-pole magnet technology, applied in the direction of converting sensor output, using electric/magnetic devices to transfer sensing components, instruments, etc., can solve the problems of flux loss and synthetic magnetic field not being optimized, and achieve reliable angle measurement, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

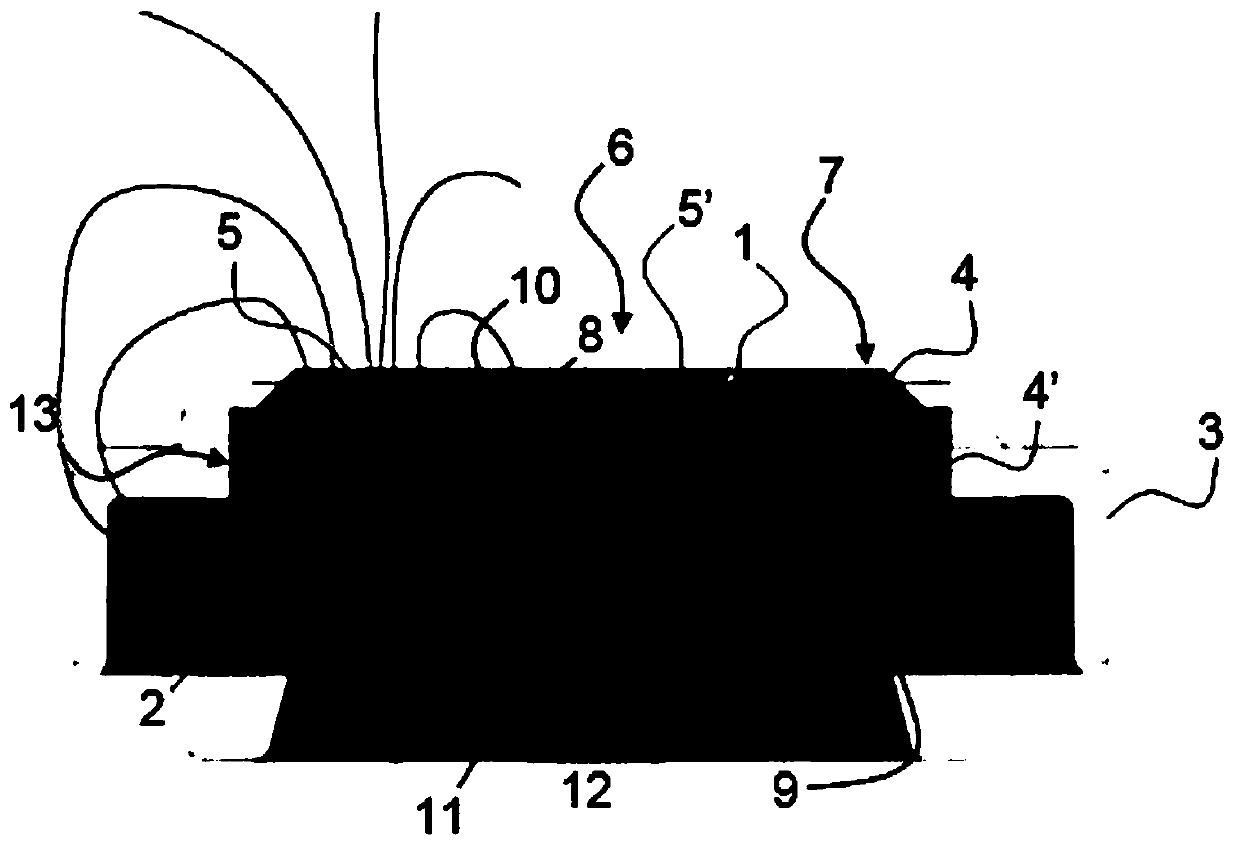

[0038] The invention relates to an angle sensor for use in components of a vehicle motor, such as an electric throttle controller (ETC) or an gas recirculation valve (EGR), for example to detect and / or precisely control the angular position of a valve. The angle sensor consists of two probes sensitive to magnetic fields. This type of angle sensor is called a differential angle sensor.

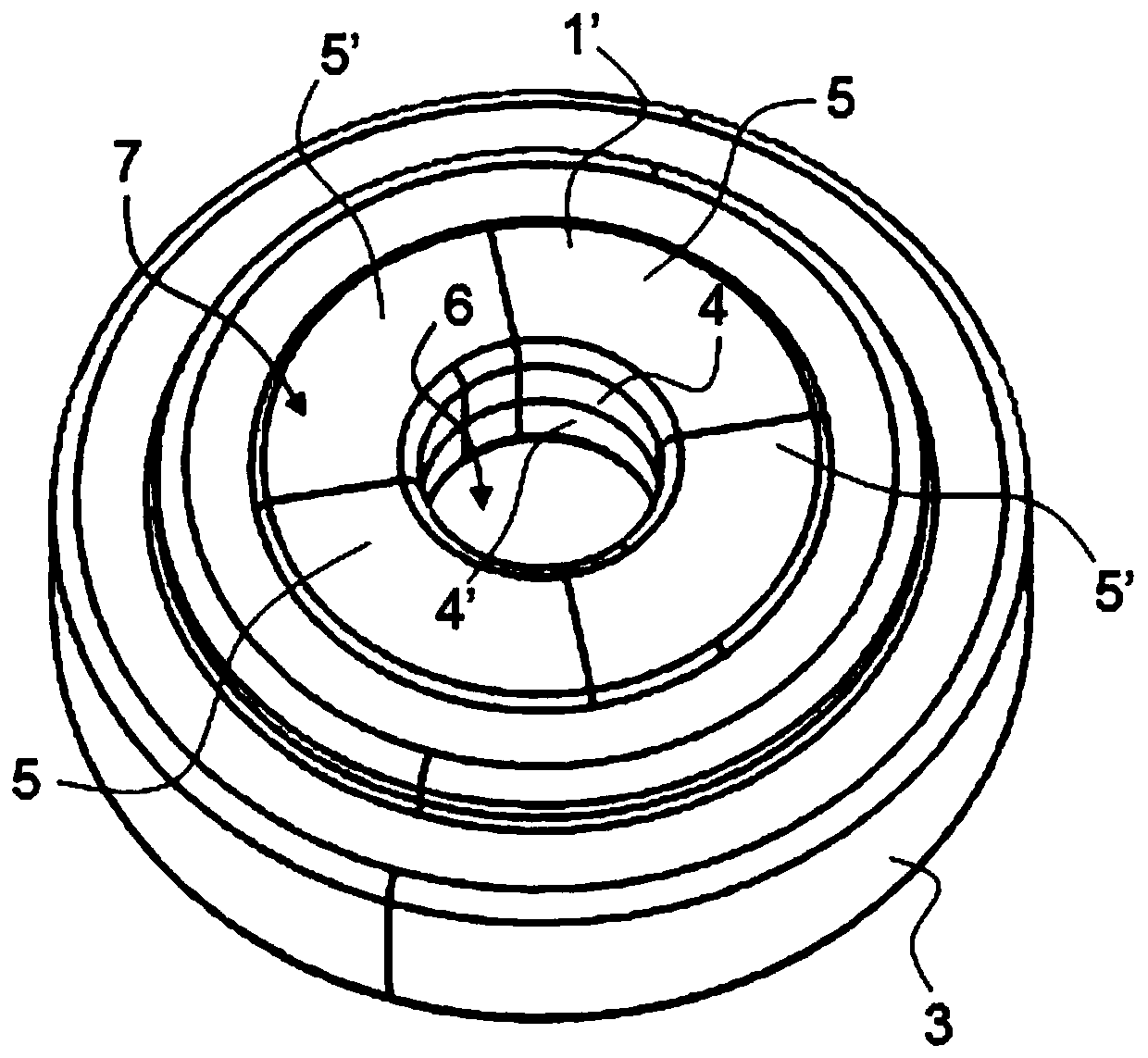

[0039] figure 1 is a schematic diagram of a prior art magnet 1'.

[0040] The angle sensor comprises an axial flux magnet 1 ′ fixed in an annular support 3 .

[0041] The assembly formed by the magnet 1' and the support 3 is intended to be fixed on a movable element of the vehicle motor, such as a shaft actuating a flap (not shown for simplicity).

[0042] Each probe sensitive to a magnetic field is able to detect changes in the magnetic field generated by the magnet 1' as it rotates, thereby making a differential measurement.

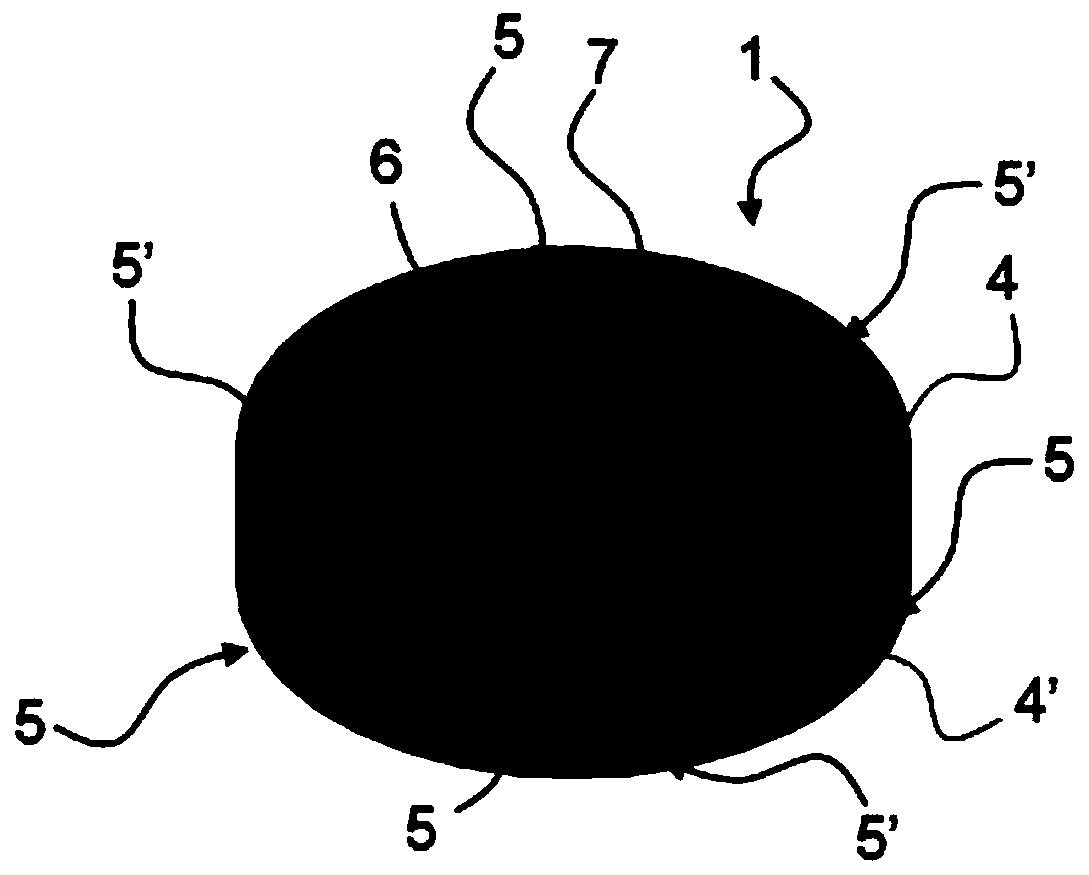

[0043] like figure 2 As shown, in the context of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com