Locally-replaceable bridge support and replacement method

A bridge support and partial technology, which is applied in the direction of bridges, bridge parts, bridge maintenance, etc., can solve the problems of large concrete, short service life of the main support core, and low practicability, so as to reduce the degree of damage, reduce maintenance costs, and not easily rusty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

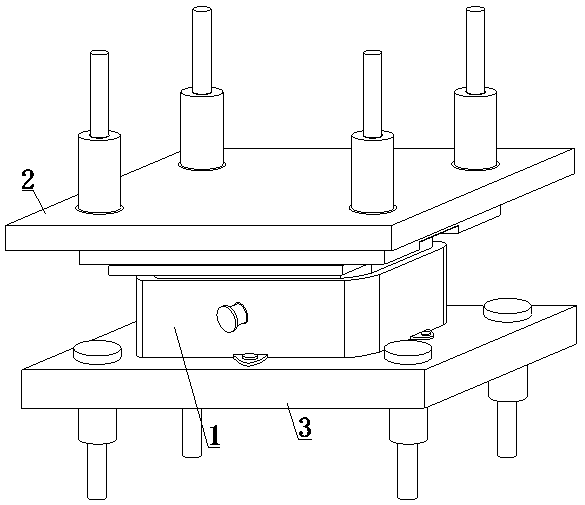

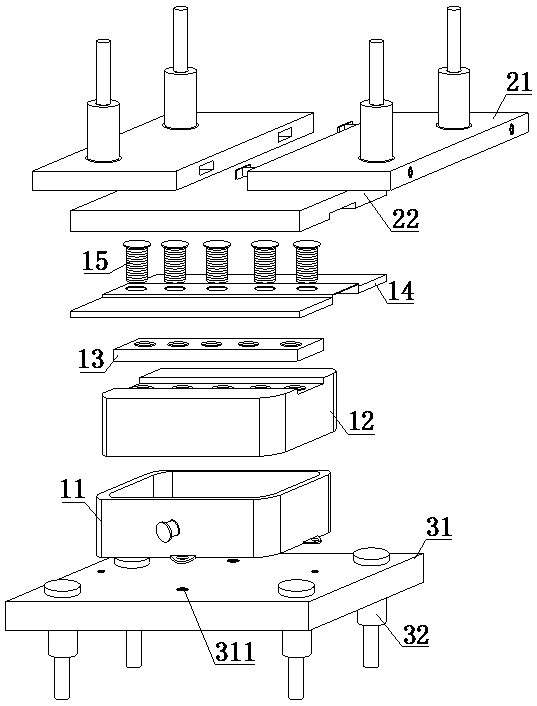

Embodiment 1

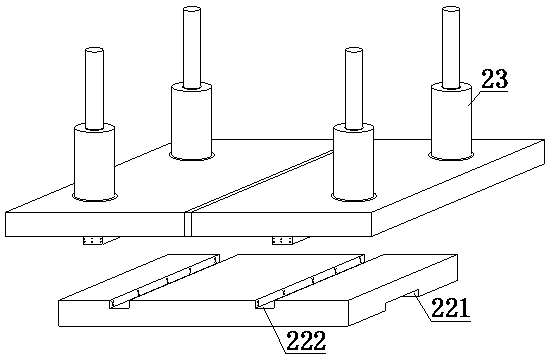

[0047] Embodiment 1: When the embedded steel plate A21 is damaged, it is necessary to use a slotting tool to break the bridge and take out the damaged embedded steel plate A21, because the embedded steel plate A21 is composed of the first steel plate 211 and the second steel plate 212, wherein Take one of them if it is damaged, and when taking out one of them again, rotate the movable steel pin 2122 so that the blocking piece 21221 can break away from the vertical groove 2112. After installing the new pre-embedded steel plate A21, block it with cement. Fill between the upper anchor bolt 23 and the cement with epoxy mortar.

Embodiment 2

[0048] Embodiment 2: When the main support core 12 is damaged, first, it is necessary to use an external hydraulic jack to slightly separate the bridge from the pier, use a steel plate to replace the support, and then pull the main support core 12 out of it, and second, loosen the locking bolts 112, separate the extruding block 113 from the supporting core 12, unscrew the lengthened locking bolt 15, and take out the main supporting core 12, if the main supporting core 12 has been deformed, then use the extruding block 113 to loosen back and forth, The main support core 12 is peeled off therefrom.

Embodiment 3

[0049] Embodiment 3: When the stainless steel plate 14 is damaged, use an external hydraulic jack to slightly separate the bridge from the pier. If the overall placement time is long, it is necessary to use the airflow generated by the air pump to separate the upper support plate 22 and the stainless steel plate. The dust and sand between 14 are blown away to prevent it from being hindered during the extraction process, and then the lengthened locking bolt 15 is unscrewed, and the stainless steel plate 14 is removed through the sliding of the chute A141, and a new one is replaced. Lengthening locking bolt 15 is screwed in, finishes changing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com