Method for recycling zinc ferrite solution

A technology of zinc-ferric acid and ferric acid, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of intensifying the reaction of iron-zinc alloys, reducing the adhesion between the coating and the substrate of the coating, etc. problems, to achieve the effect of wide source of raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

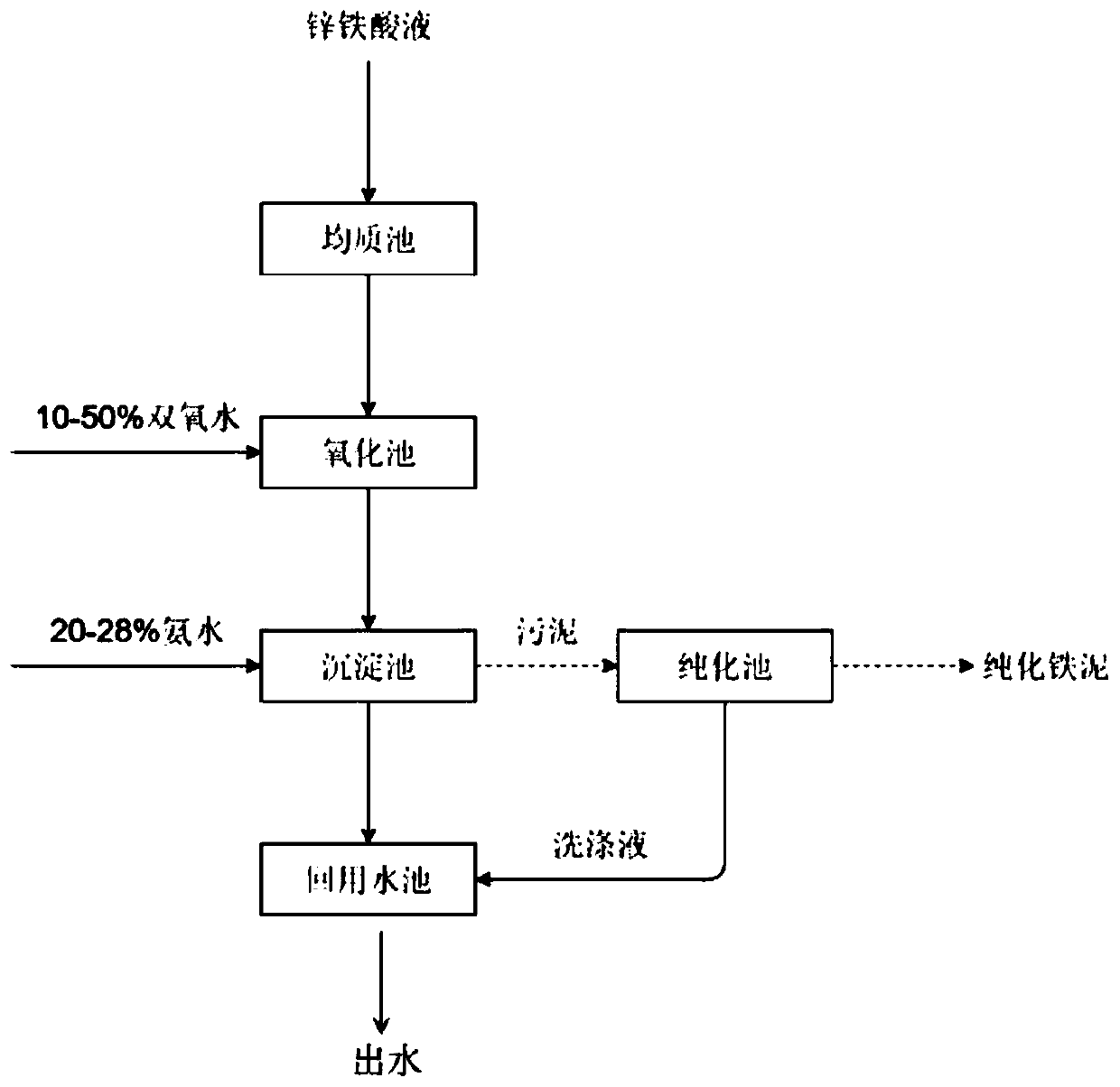

Image

Examples

Embodiment 1

[0036]The situation of zinc-ferric acid solution produced by a galvanizing plant is as follows: 10 cubic meters per day, pH is 0.1, total iron concentration is 56g / L, and zinc concentration is 9g / L.

[0037] The concrete steps of this zinc-ferric acid solution reuse are:

[0038] Step S0: Collect the zinc-ferric acid solution into the homogeneous tank for mixing, and mix thoroughly to keep the water quality stable.

[0039] Step 1: Send the zinc-ferric acid solution in the homogeneous tank into the oxidation tank, open the dosing tank, and automatically control the hydrogen peroxide with a mass concentration of 10% from the dosing tank to the oxidation tank for oxidation through the automatic control valve. The molar ratio of content is 4:1, and the flow rate is controlled at 0.2m 3 / h. The oxidation reaction time at the end of dosing was 130min.

[0040] Step 2: After the oxidation reaction is completed, send the oxidized zinc-ferric acid solution into the primary sediment...

Embodiment 2

[0044] The situation of zinc-ferric acid solution produced by a galvanizing plant is as follows: 40 cubic meters per day, pH is 1, total iron concentration is 34g / L, and zinc concentration is 5g / L.

[0045] The concrete steps of this zinc-ferric acid solution reuse are:

[0046] Step S0: Collect the zinc-ferric acid solution into the homogeneous tank for mixing, and mix thoroughly to keep the water quality stable.

[0047] Step 1: Send the zinc-ferric acid solution in the homogeneous tank into the oxidation tank, open the dosing tank, and automatically control the hydrogen peroxide with a mass concentration of 35% from the dosing tank to the oxidation tank for oxidation through the automatic control valve. The molar ratio of content is 3:1, and the flow rate is controlled at 0.2m 3 / h. The oxidation reaction time at the end of dosing was 90 minutes.

[0048] Step 2: After the oxidation reaction is completed, send the oxidized zinc-ferric acid solution into the primary sedim...

Embodiment 3

[0052] The situation of zinc-ferric acid solution produced by a galvanizing plant is as follows: 30 cubic meters per day, pH is 1, total iron concentration is 19g / L, and zinc concentration is 8g / L.

[0053] The concrete steps of this zinc-ferric acid solution reuse are:

[0054] Step S0: Collect the zinc-ferric acid solution into the homogeneous tank for mixing, and mix thoroughly to keep the water quality stable.

[0055] Step 1: Send the zinc-ferric acid solution in the homogeneous tank into the oxidation tank, open the dosing tank, and automatically control the hydrogen peroxide with a mass concentration of 50% from the dosing tank to the oxidation tank for oxidation through the automatic control valve. The molar ratio of the content is 2.5:1, and the flow rate is controlled at 0.3m 3 / h. The oxidation reaction time at the end of dosing was 80 minutes.

[0056] Step 2: After the oxidation reaction is completed, send the oxidized zinc-ferric acid solution into the primary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com