High-hydrophobicity wood sponge with electric-thermal conversion capability as well as preparation method and application thereof

A high hydrophobicity, electrothermal conversion technology, used in wood treatment, impregnating wood, manufacturing tools, etc., can solve problems such as practical application limitations, blockage of material channels, poor crude oil fluidity, etc. The effect of fast electrothermal conversion capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

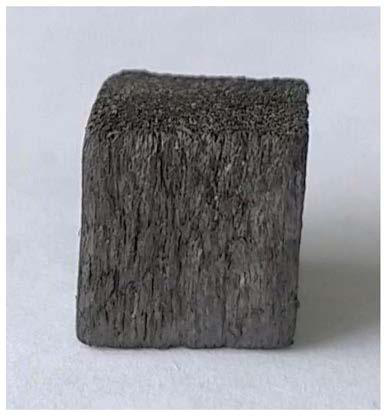

Image

Examples

Embodiment 1

[0032] A preparation method of highly hydrophobic wood sponge with electrothermal conversion ability, comprising the following steps:

[0033] 1) Prepare a sodium hypochlorite solution with a mass concentration of 2%, adjust the pH value to 3.5 with acetic acid, heat up to 100° C. 3 The balsa wood (balsa wood is also called balsa wood) is taken out after immersion treatment for 12 hours to remove the lignin component.

[0034] 2) preparing a sodium hydroxide solution with a mass concentration of 8% and raising the temperature to 80° C., immersing the balsa wood treated in step 1) for 12 hours and taking it out to remove the hemicellulose component;

[0035] 3) Take out the balsa wood treated in step 2) and wash it with water, freeze it at -15°C for 1 hour, then freeze-dry it at -50°C for 12 hours, put the obtained balsa wood into the aqueous solution of graphene oxide and ascorbic acid for 30 minutes Take out, the mass concentration of graphene oxide in the aqueous solution o...

Embodiment 2

[0045] A preparation method of highly hydrophobic wood sponge with electrothermal conversion ability, comprising the following steps:

[0046] 1) Prepare a sodium hypochlorite solution with a mass concentration of 6%, adjust the pH value to 4 with formic acid, heat up to 85° C. 3 The balsa wood was soaked for 12 hours and then taken out to remove lignin components.

[0047] 2) preparing a sodium hydroxide solution with a mass concentration of 12% and raising the temperature to 95° C., soaking the treated balsa wood in step 1) for 8 hours and taking it out to remove the hemicellulose component;

[0048] 3) After washing the balsa wood treated in step 2), first freeze it at -5°C for 3h, then freeze-dry it at -50°C for 24h, put the obtained balsa wood into an aqueous solution of graphene oxide and ascorbic acid (graphite oxide The mass concentration of alkene is 1%; the mass ratio of ascorbic acid and graphene oxide is 0.3:1) after soaking for 300min, take it out, and then place...

Embodiment 3

[0054] A preparation method of highly hydrophobic wood sponge with electrothermal conversion ability, comprising the following steps:

[0055] 1) Prepare a sodium hypochlorite solution with a mass concentration of 1%, adjust the pH value to 3 with hydrochloric acid, heat up to 100°C, and prepare a solution with a size of 10mm×10mm×10mm and a density of 120mg / cm 3 The balsa wood was soaked for 6 hours and then taken out to remove the lignin components.

[0056] 2) preparing a sodium hydroxide solution with a mass concentration of 7% and raising the temperature to 70° C., immersing the treated balsa wood in step 1) for 6 hours and taking it out to remove the hemicellulose component;

[0057] 3) After taking out the balsa wood treated in step 2) and washing it with water, first freeze it at -10°C for 1.5h, then freeze-dry it at -50°C for 8h, put the obtained balsa wood into an aqueous solution of graphene oxide and ascorbic acid ( The mass concentration of graphene oxide is 1%; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com