Microwave ablation catheter tube body, manufacturing method and microwave ablation catheter using the same

A microwave ablation, catheter technology, applied in catheters, microwave surgical instruments, parts of surgical instruments, etc., can solve the problems of tube body breakage, high hardness, irreversible creases, etc., and achieve high torque and high pushability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

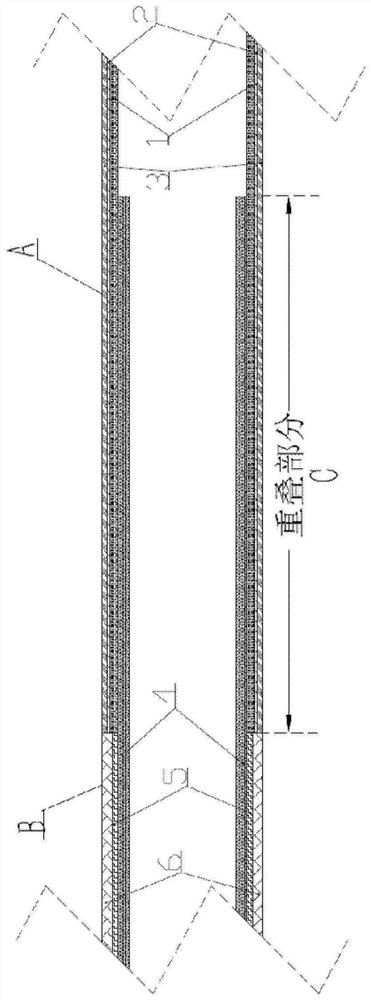

[0025] The invention discloses a microwave ablation catheter tube body, which comprises a front end tube and a rear end tube, wherein the front end tube and the rear end tube have overlapping parts, and the overlapping parts of the front end tube and the rear end tube are connected by welding or bonding. part of the body.

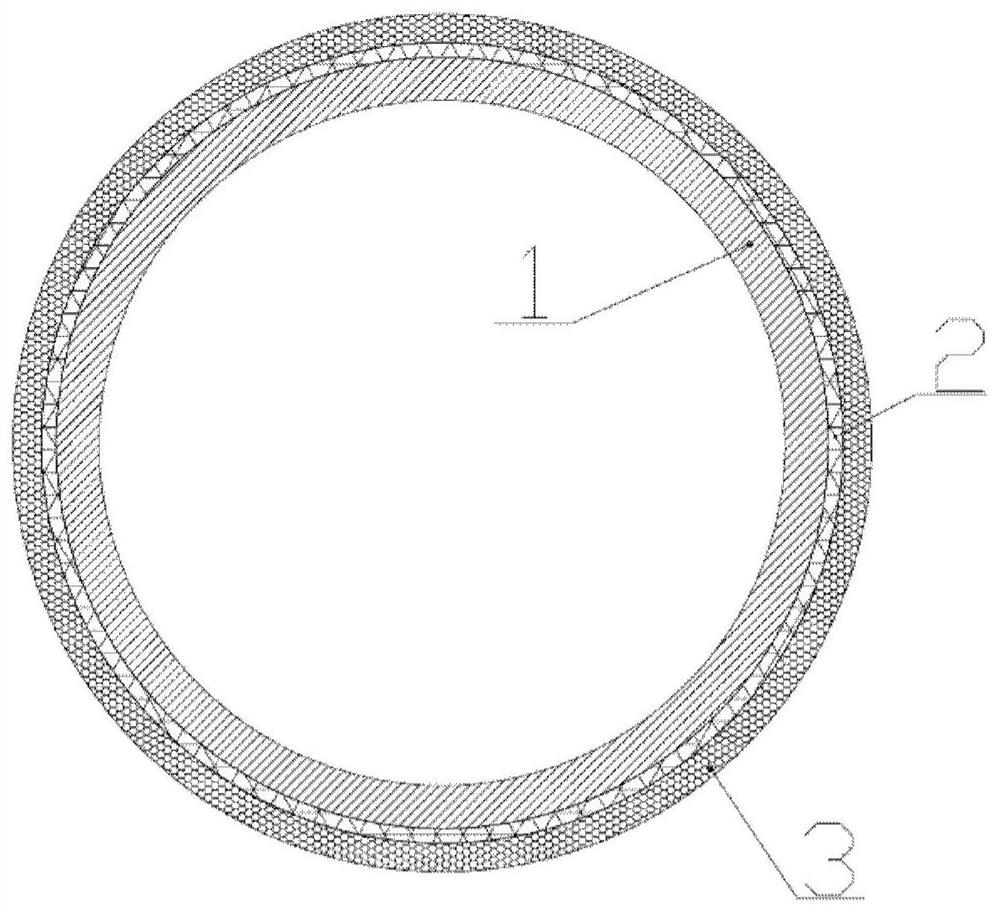

[0026] Preferably, the front-end tube includes an inner tube and an outer tube, and a glue layer is formed between the inner tube and the outer tube, that is, the connection between the inner tube and the outer tube is glued.

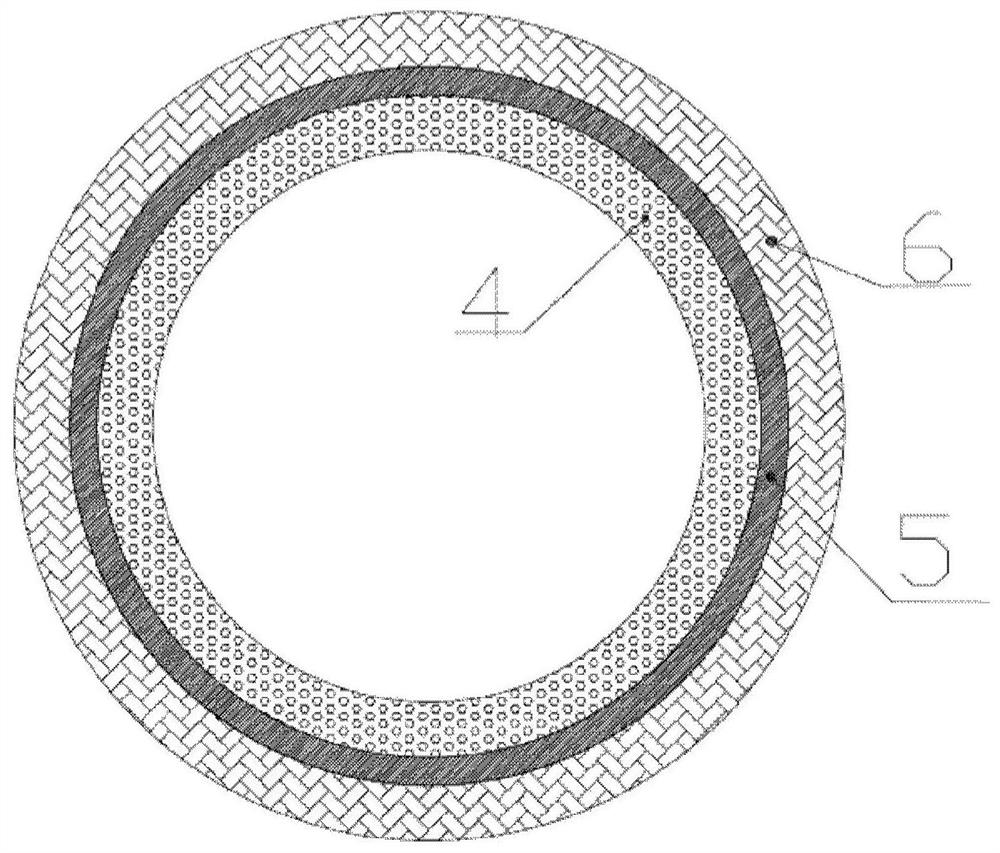

[0027] Preferably, the rear-end pipe includes three layers, namely an inner layer pipe, an intermediate layer pipe and an outer layer pipe, and the connection method of these th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com