A continuous frying device for hollow crisp production

A hollow and deep-fried box technology, applied in the direction of oil/fat baking, etc., can solve the problems of manpower consumption and low efficiency, and achieve the effects of improving production efficiency, simplifying the mechanism, and shortening the window period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

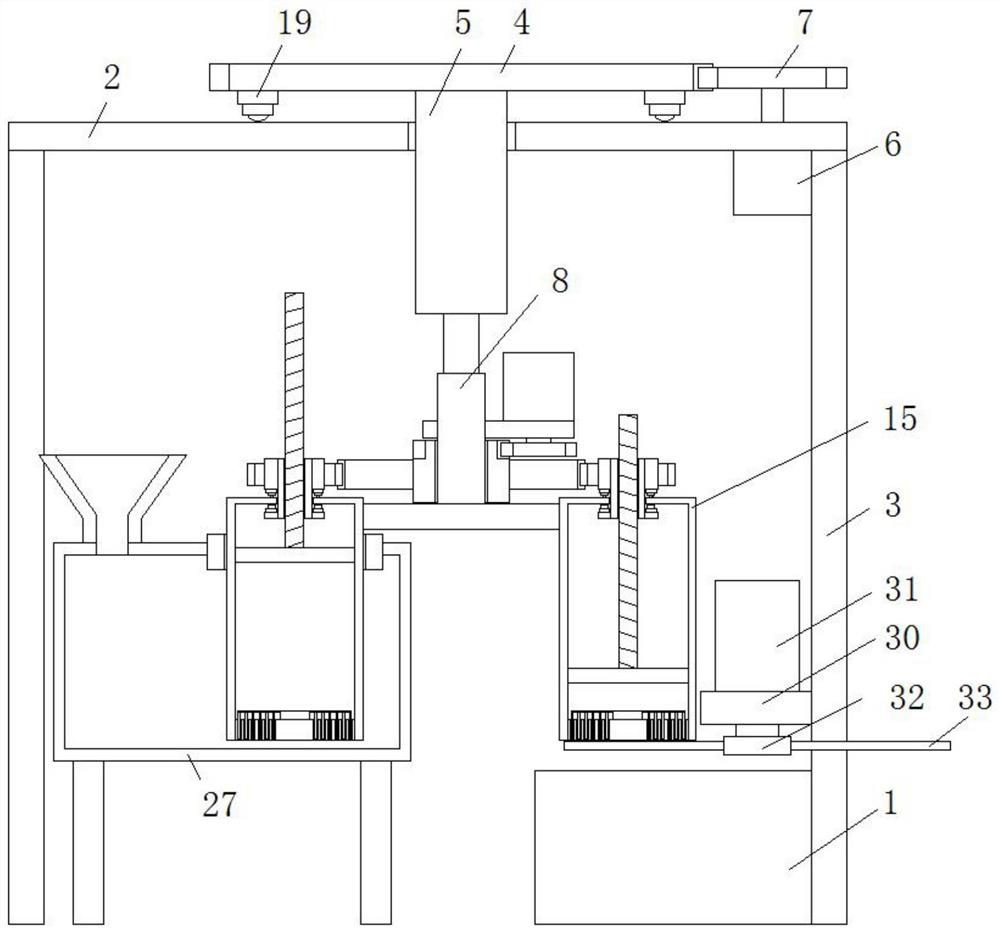

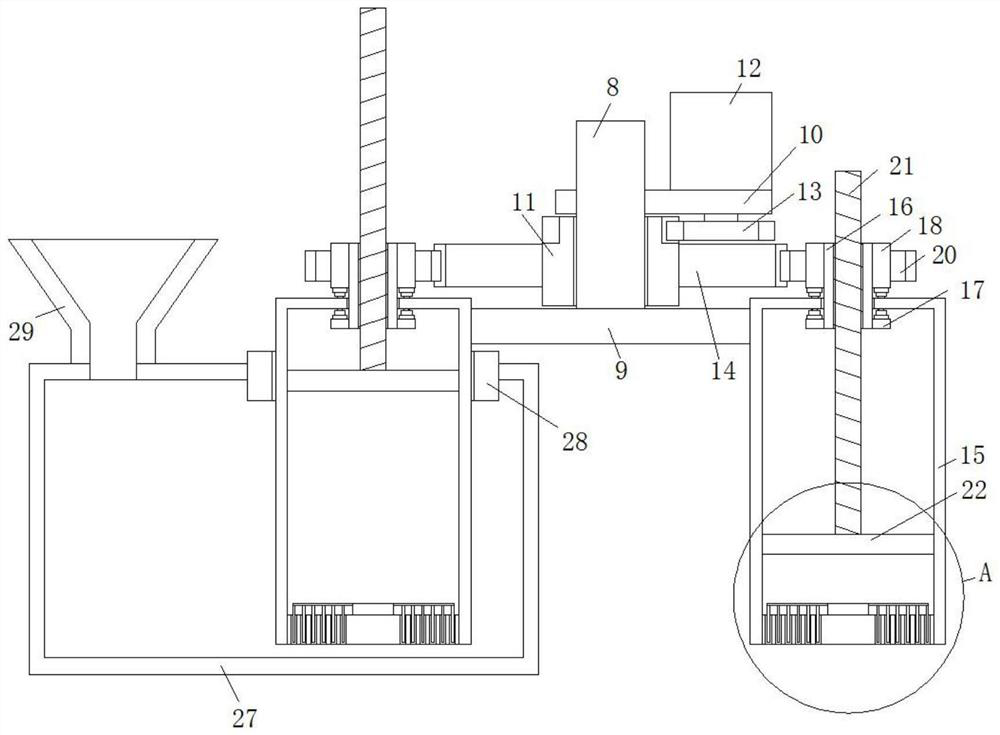

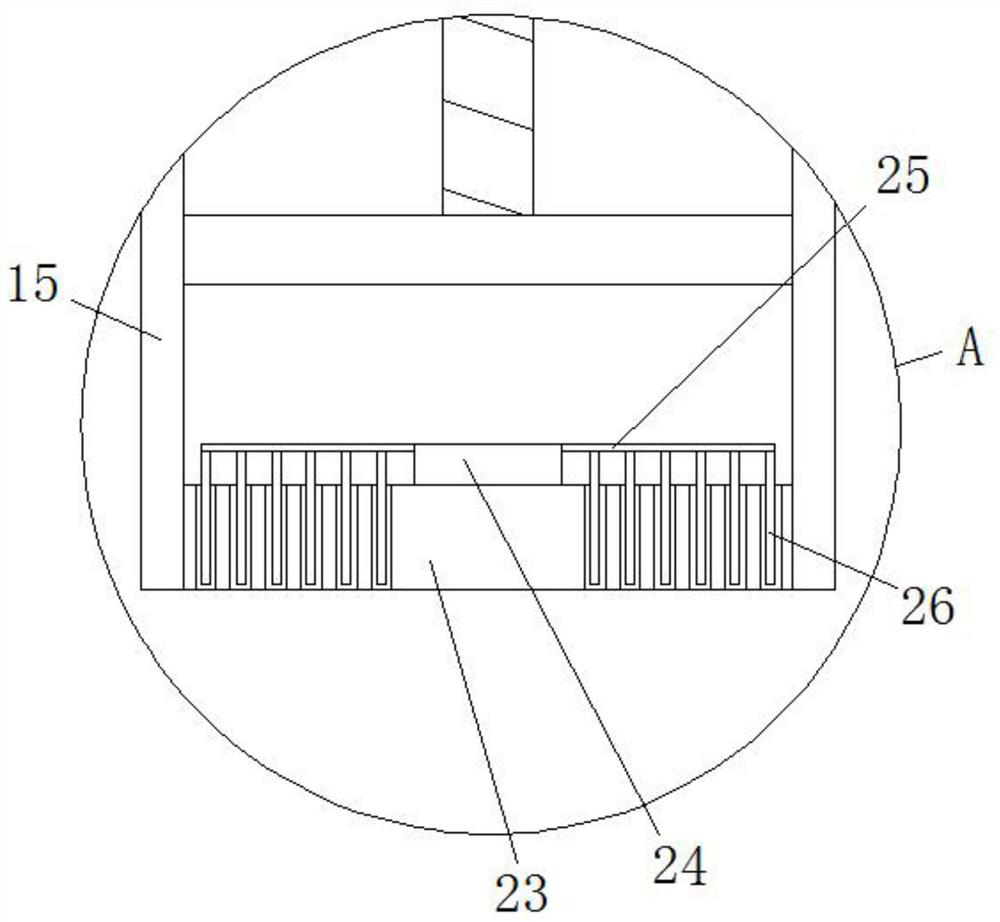

[0022] refer to Figure 1-4 , a continuous frying device for hollow brittle production, comprising a frying box 1, the top of the frying box 1 is provided with a feeding mechanism, the feeding mechanism includes a top plate 2, and the four corners of the bottom side of the top plate 2 are fixedly connected with legs 3, The vertical top of the top plate 2 is provided with an installation disc 4, and the bottom side of the installation disc 4 is fixed with a cylinder 5 by bolts. The body of the top plate 2 is provided with a vertical through hole, and the cylinder 5 passes through the vertical through hole. However, one side of the top plate 2 is fixedly installed with a motor 6 by bolts, and the output shaft of the motor 6 is connected with a gear 7 behind, and the vertical side of the installation disc 4 is provided with a tooth groove and meshed with the gear 7. , the output rod of the cylinder 5 is fixedly connected with the central axis column 8, the bottom end of the centr...

Embodiment 2

[0025] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the mounting ring 10 is fixedly connected to the central axis column 8, the collar 11 is rotatably set on the outside of the central axis column 8, and the collar 11 is located on the central axis plate 9 and mounting ring 10.

[0026] In this embodiment, while the installation ring 10 is used as the installation base of the second motor 12 , it also defines the vertical height position of the collar 11 relative to the central axis column 8 .

Embodiment 3

[0028] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top side of the scraper 33 is in sliding contact with the bottom side of the bottom template 23 , and the scraper 33 is located vertically above the fryer 1 .

[0029] In this embodiment, through the setting of the scraper 28, the material falling from the retrieving box 15 is cut to form a hollow brittle section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com