Moisture-barrier laminate film

A laminated film, inorganic barrier layer technology, applied in the direction of layered products, coatings, metal layered products, etc., to achieve the effects of preventing cracking, improving productivity, and excellent moisture barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

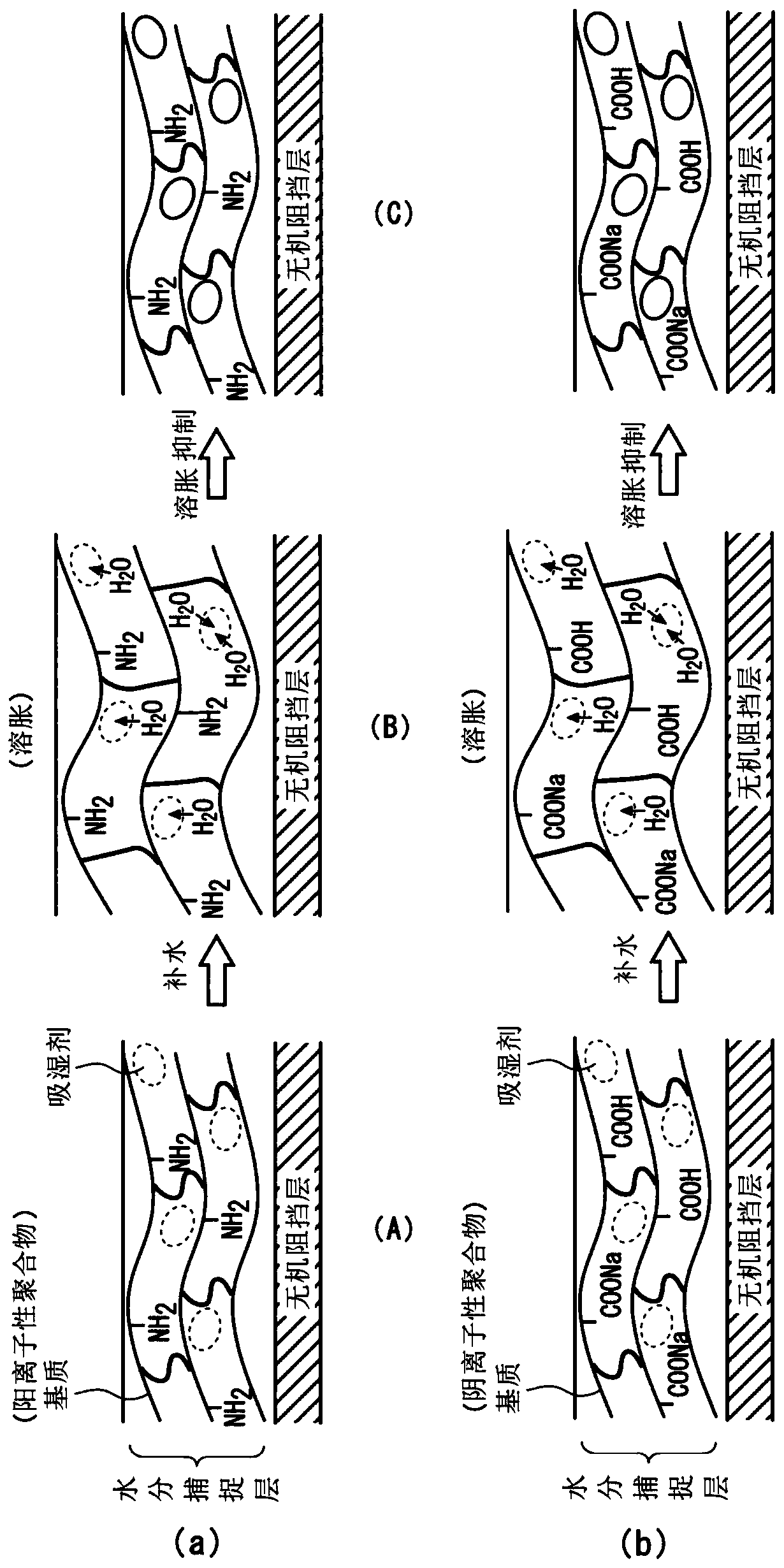

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0252] An isocyanate-reactive resin solution (wpb-341, 30% solid content, supplied by Mitsui Kagaku Co. Manufactured).

[0253] The isocyanate reactive resin solution and the silane coupling agent (3-glycidoxypropyltrimethoxysilane) as the curing agent are 5 with respect to the solid content of 100 parts by weight of the isocyanate reactive resin solution with respect to the solid content of the curing agent. Amounts of parts by weight are blended. The blend thereof was then diluted with a mixed solvent of water and 2-propanol to prepare an isocyanate-based coating liquid having a solid content of 20%.

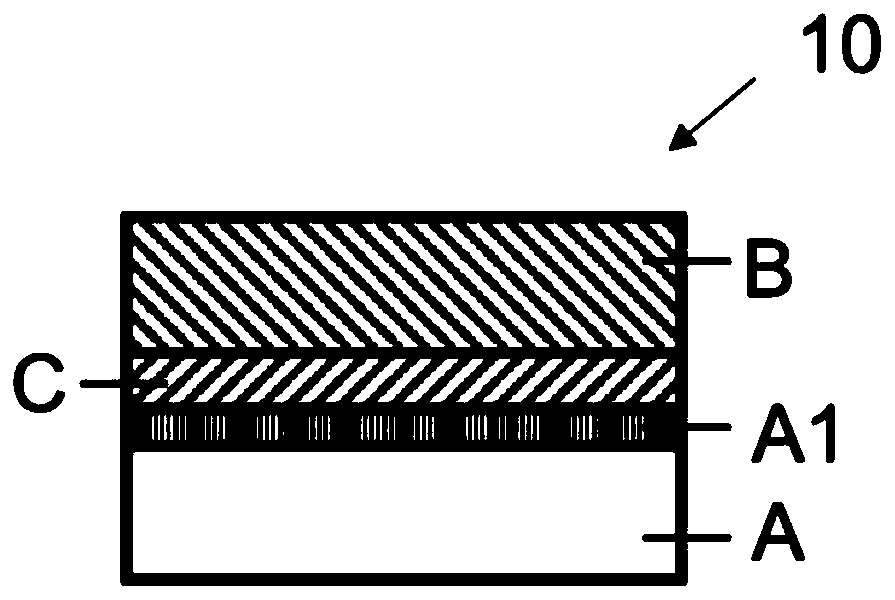

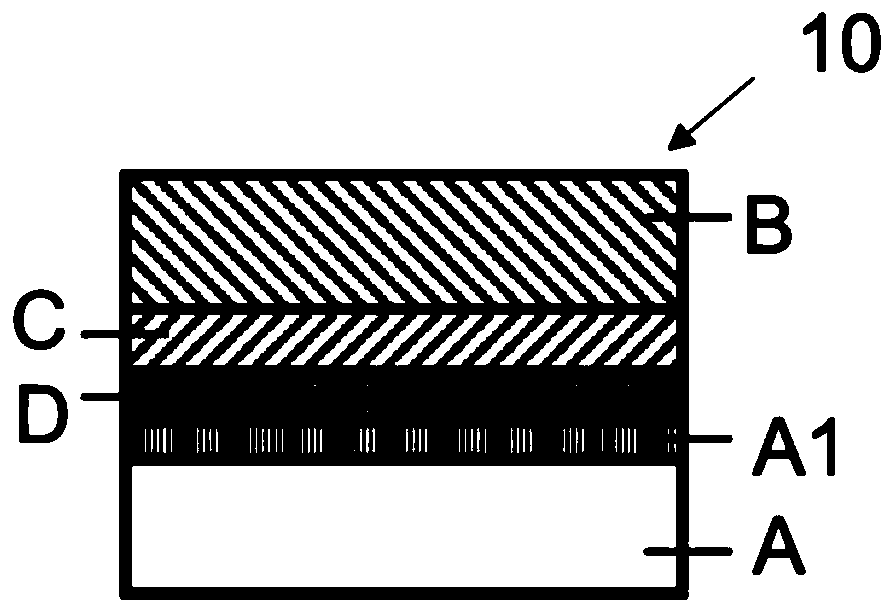

[0254] A commercially available barrier film (Toppan printing, GL-RD, substrate: PET (12 μm), manufactured by Toppan Insatsu Co.) having a protective layer (D) on a silicon oxide layer (inorganic barrier layer) was provided. The protective layer (D) includes polyvinyl alcohol and tetraethoxysilane.

[0255] The above isocyanate-based coating liquid was applied onto the prot...

Embodiment 2

[0258] An isocyanate-based coating liquid was prepared in the same manner as in Example 1, except that the amount of solid content of the curing agent was changed to 20 parts by weight relative to 100 parts by weight of the solid content of the main polymer solution.

[0259] A moisture barrier laminated film 10 was obtained by the same method as in Example 1 except that the above isocyanate-based coating liquid was used.

Embodiment 3

[0261] The isocyanate reactive resin solution provided in Example 1 was used. This solution was blended with blocked isocyanate (XWB-F206MEDG manufactured by Mitsui Kagaku Co.) as a curing agent in an amount of 10 parts by weight of the solid content of the curing agent relative to 100 parts by weight of the solid content of the main ingredient. The blend thereof was diluted with a mixed solvent of water and 2-propanol, thereby preparing an isocyanate-based coating liquid containing 20% solid content.

[0262] A moisture barrier laminated film 10 was obtained by the same method as in Example 1 except that the above isocyanate-based coating liquid was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com