Method for preparing spherical crystal film rubrene through induction of rigid structure polymer

A rigid polymer, spherical crystal technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problem of low quality coverage of thin-film rubrene spherulites, and rubrene is prone to secondary dissolution. , the use of large-scale equipment and other problems, to achieve the effect of rapid industrialization, non-toxic price, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

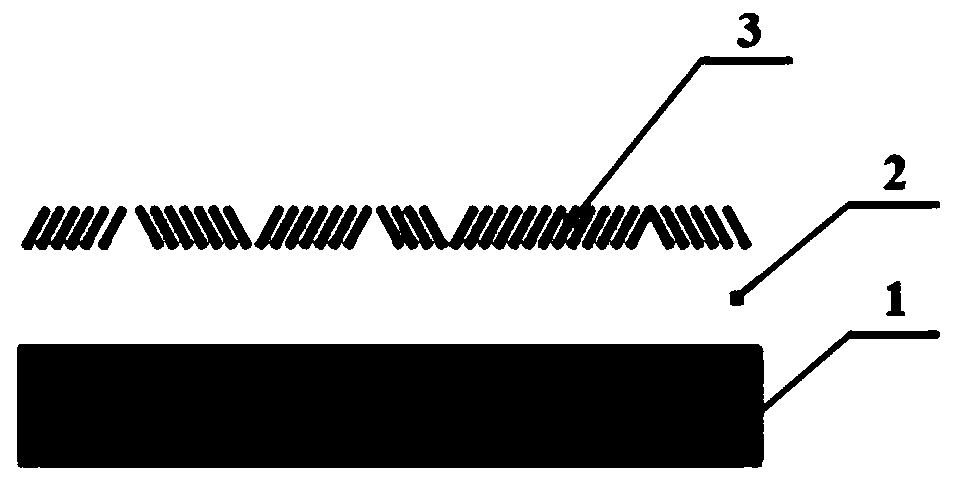

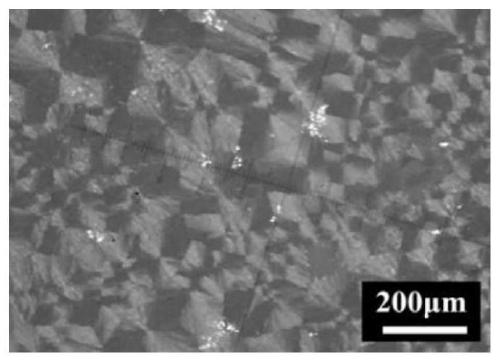

[0041] Spherical crystal film-like rubrene was induced by rigid structure polymer, the rigid structure polymer is PET.

[0042] First, cut a commercial 5cm×5cm FTO conductive glass sheet from the non-conductive side into 1cm×1cm as the substrate and wash and dry it; then prepare 1mL PET polymer solution with trifluoroacetic acid as solvent, the mass concentration is 2.5mg / mL; Using chloroform as the solvent and rubrene as the solute, the rubrene-chloroform solution was prepared under the condition of red light illumination in a dark room, with a mass concentration of 9.5mg / mL; then the PET polymer solution and rubrene- The chloroform solution was spin-coated on the FTO substrate respectively; finally, the FTO sheet was heat-treated under red light illumination in a dark room and wrapped in tin foil to avoid light.

[0043] The heat treatment parameters are as follows: heat preservation on a hot stage at 160°C for 50s; heat preservation on a hot stage at 135°C for 280s.

Embodiment 2

[0045]Spherical crystal film-like rubrene was induced by rigid structure polymer, the rigid structure polymer is PET.

[0046] First, a commercial 5cm×5cm FTO conductive glass sheet was cut from the non-conductive side into 1cm×1cm as the substrate and cleaned and dried; then 1mL PET polymer solution was prepared with trifluoroacetic acid as the solvent, and the mass concentration was 3mg / mL; Chloroform is a solvent, rubrene is a solute, and the rubrene-chloroform solution prepared under the condition of red light illumination in a dark room has a mass concentration of 10 mg / mL; Spin-coat on the FTO substrate respectively; finally, heat-treat the FTO sheet under red light lighting conditions in a dark room and wrap it in tin foil to avoid light.

[0047] The heat treatment parameters are as follows: heat preservation on a hot stage at 170°C for 60s; heat preservation on a hot stage at 140°C for 300s.

Embodiment 3

[0049] Spherical crystal film-like rubrene was induced by rigid structure polymer, the rigid structure polymer is PET.

[0050] First, cut a commercial 5cm×5cm FTO conductive glass sheet from the non-conductive side into 1cm×1cm as the substrate and wash and dry it; then prepare 1mL PET polymer solution with trifluoroacetic acid as solvent, the mass concentration is 2.8mg / mL; Using chloroform as the solvent and rubrene as the solute, the rubrene-chloroform solution prepared under red light lighting conditions in a dark room has a mass concentration of 10.2mg / mL; then use a homogenizer to mix the PET polymer solution and rubrene- The chloroform solution was spin-coated on the FTO substrate respectively; finally, the FTO sheet was heat-treated under red light illumination in a dark room and wrapped in tin foil to avoid light.

[0051] The heat treatment parameters are: 175°C on a hot stage for 65s; 142°C on a hot stage for 310s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com