Railway wagon quality inspection information system

A quality inspection and information system technology, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as the inability to provide effective evidence to prove product production process control, failure and defect repair cannot be quantified, product quality problems hinder, etc., to achieve convenient system The effects of standardized management, easy quality traceability, improved error prevention ability and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

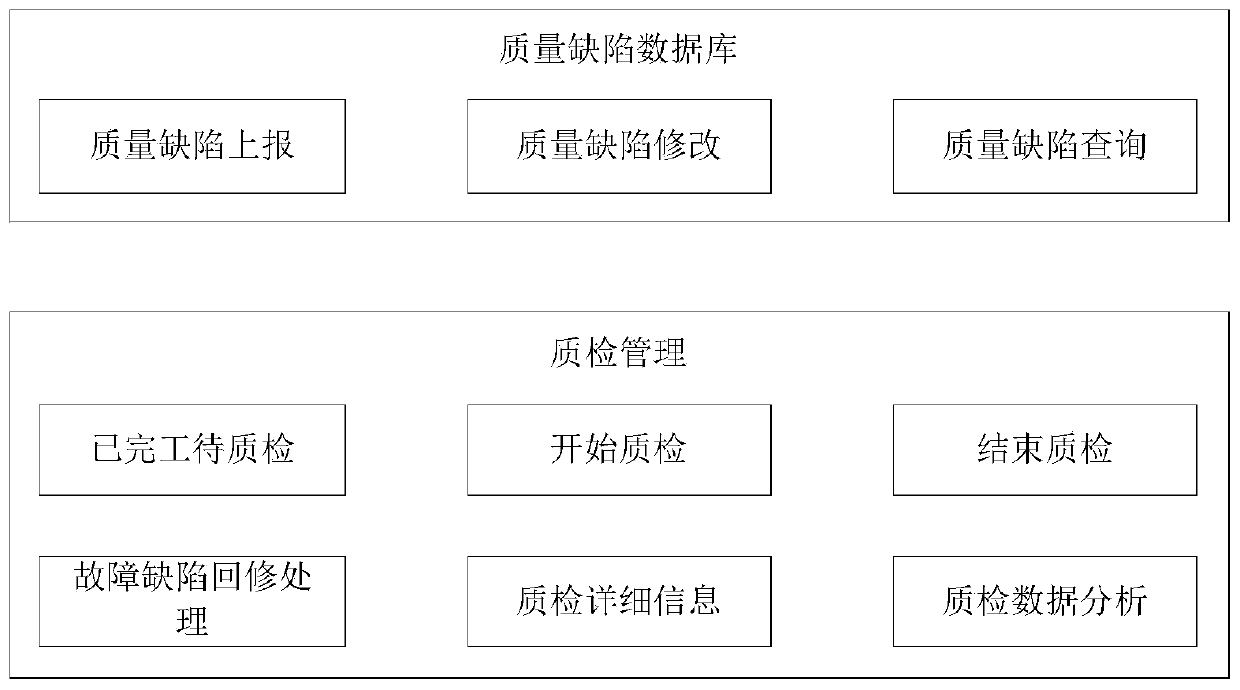

[0018] Such as figure 1 A railway wagon quality inspection information system shown includes two modules, a quality defect database and a quality inspection management module, wherein the quality defect database module includes three modules: quality defect reporting, quality defect modification, and quality defect query; quality inspection management The module includes six modules: completed pending quality inspection, start quality inspection, end quality inspection, fault defect repair processing, quality inspection detailed information, and quality inspection data analysis.

[0019] The quality defect database is used to manage and store Class A defects, Class B defects, and Class C defects corresponding to different models and parts, as well as specific defect descriptions corresponding to different defects, where Class A def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com