Laser radar

一种激光雷达、雷达的技术,应用在测距领域,能够解决电磁感应线圈通信带宽无法满足高线束激光雷达通信需求、不可避免磨损问题、信号传输复杂等问题,达到有利于散热、成本低、提高传输量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1: A laser radar, including a main shaft, a radar rotor, a base, a first main board, a second main board, an angle measurement component, a power supply component, and a communication component;

[0073] The first main board is fixedly arranged relative to the radar rotor and the first main board is arranged around the main shaft, and the second main board is fixedly arranged relative to the base and is closer to the base than the first main board ;

[0074] The angle measurement component, the power supply component and the communication component are located between the first main board and the second main board, and at least a part of the angle measurement component, at least a part of the power supply component and at least a part of the communication component surround the spindle setting;

[0075] The angle measurement component includes a first measurement module and a second measurement module, the power supply component includes a first power supply...

Embodiment 2

[0077] Embodiment 2. The lidar according to embodiment 1, wherein, in the radial direction of the main shaft, the communication component, the power supply component and the angle measurement component are arranged in sequence, and the angle measurement component is connected to the Compared with the communication component and the power supply component, the distance from the main shaft is farther.

Embodiment 3

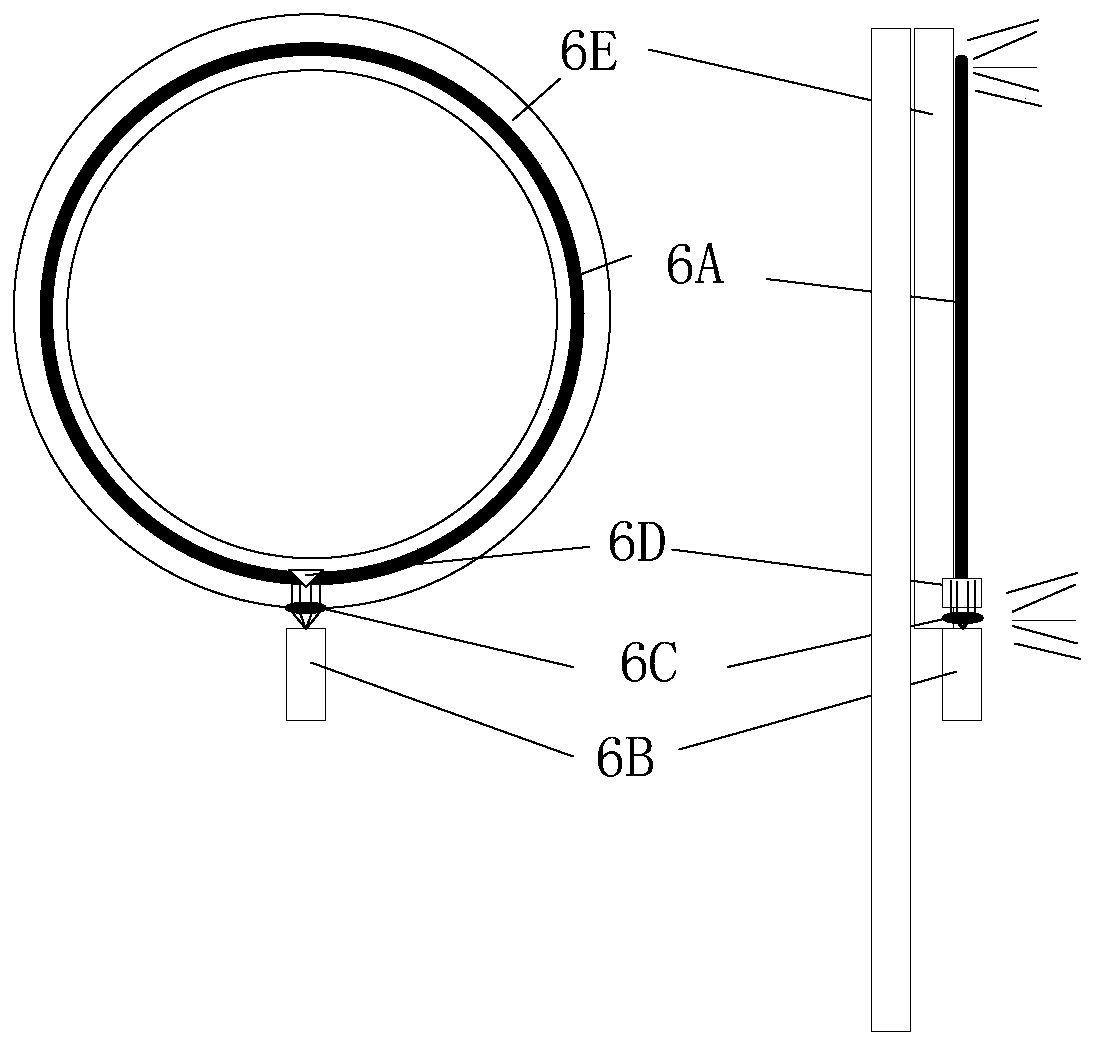

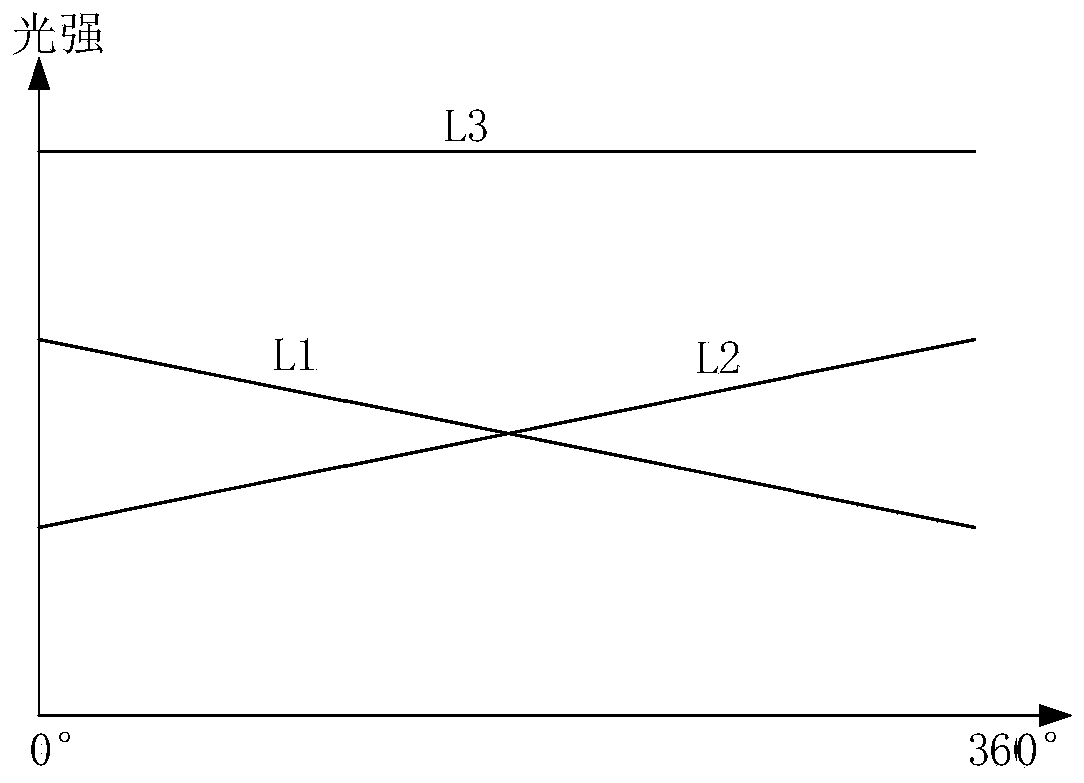

[0078] Embodiment 3. The lidar according to Embodiment 1 or 2, wherein the first communication module includes at least one light emitting element, and the second communication module includes at least one light receiving element corresponding to the light emitting element, and

[0079] The light-emitting element moves relative to the light-receiving element, and the light-receiving element is located on the light path of at least one light beam emitted by the light-emitting element;

[0080] The light-emitting element is centered on the main axis and arranged around the main axis, forming a ring-shaped light-emitting element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com