Buried heat distribution pipeline water leakage detection device and method

A technology of thermal pipelines and detection devices, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., and can solve problems such as inappropriate audio detection technology, audio detection interference, and inability to detect water leakage in non-heating seasons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

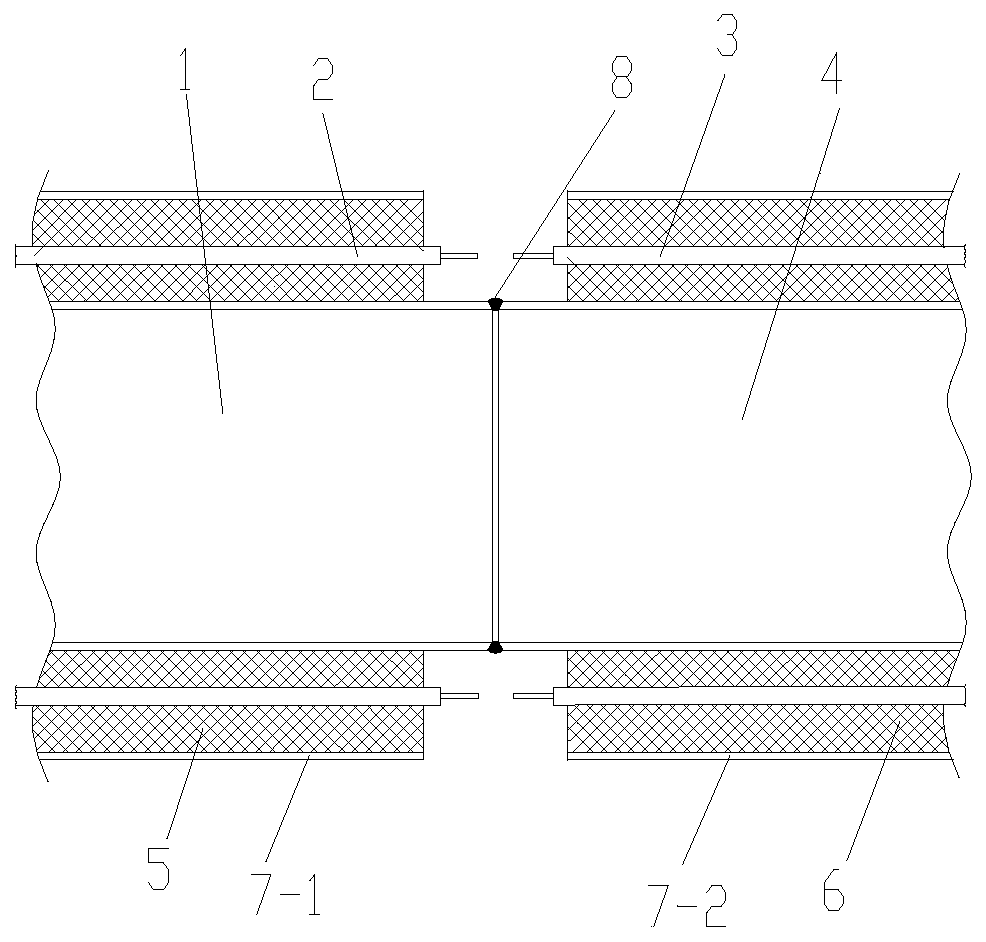

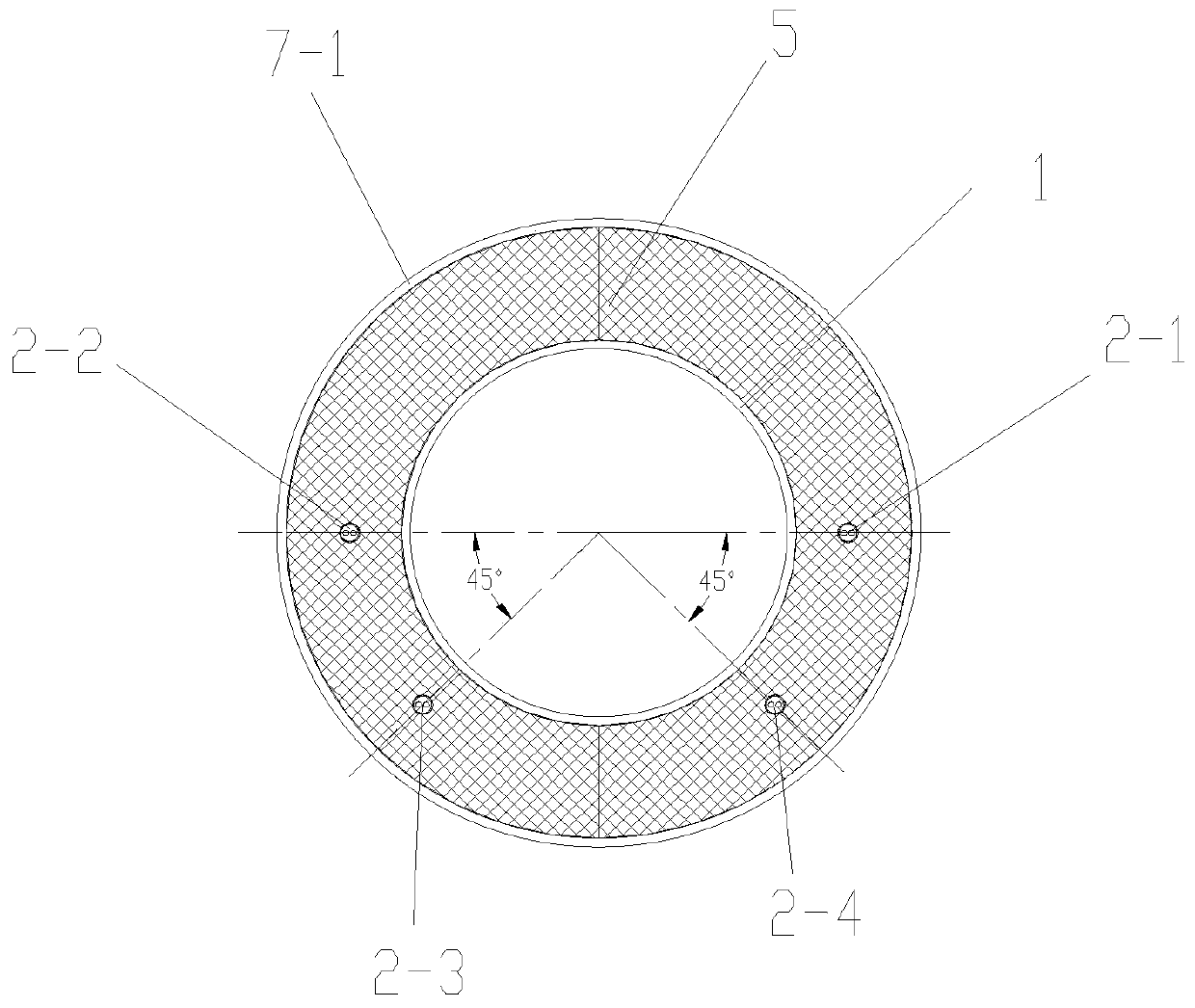

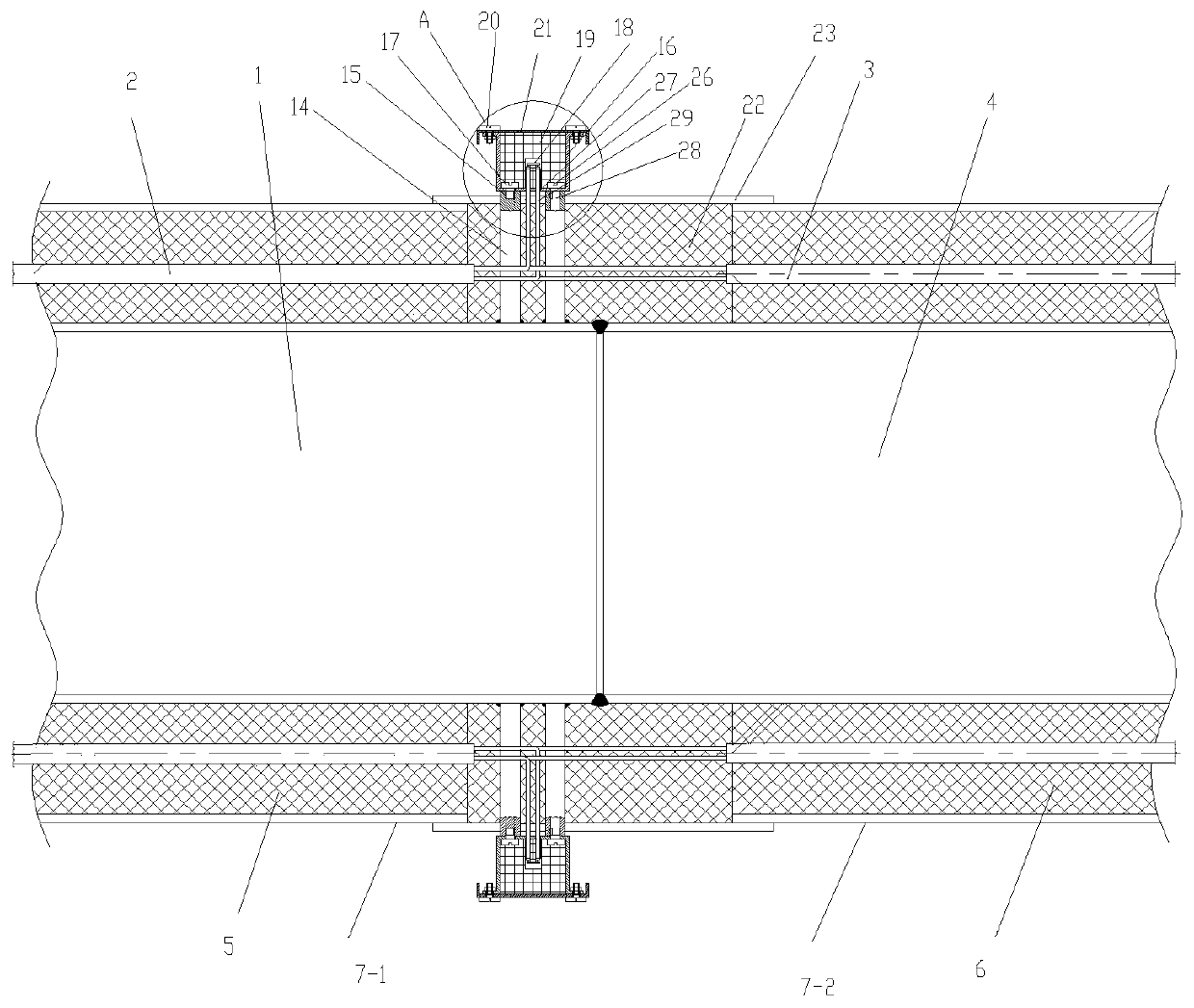

[0090] Such as Figure 1 to Figure 5 A buried thermal pipeline water leakage detection device shown includes four composite sensors arranged at the junction of two adjacent sections i-section thermal pipeline 1 and i+1-th section thermal pipeline 4, and the four composite sensors are respectively For the first composite sensor 301, the second composite sensor 302, the third composite sensor 303 and the fourth composite sensor 304, the first composite sensor 301 and the second composite sensor 302 are along the vertical direction with respect to the thermal pipeline The diameter of is arranged symmetrically, and the first composite sensor 301 and the second composite sensor 302 are located at the diameter of the thermal pipeline along the horizontal direction, and the third composite sensor 303 and the fourth composite sensor 304 are along the vertical direction of the thermal pipeline The diameter is arranged symmetrically, and the third composite sensor 303 and the fourth com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com